A Contact Relationship Model and Assembly Error Calculation Method Considering Deformation Error

A technology of deformation error and calculation method, which is applied in the direction of complex mathematical operations, etc., can solve the problems of slow calculation speed and failure to consider the geometric error of the assembly surface, etc., and achieve the effect of accurate solution results and fast calculation convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

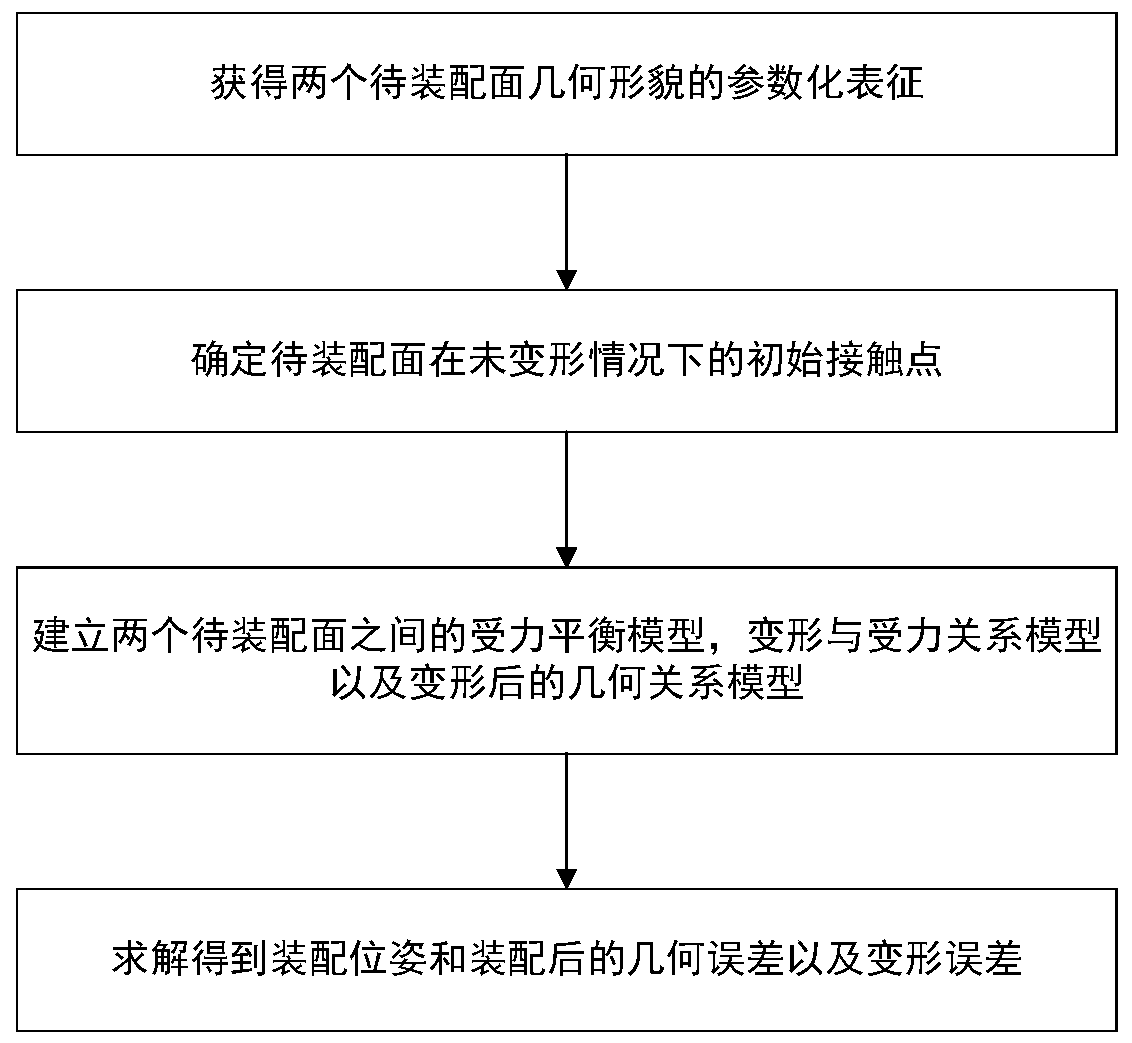

[0033] The method of the invention regards the reference plane as an ideal rigid body, and considers the influence of the deformation of another non-rigid plane matched with it on the final assembly pose. The first step of the method of the present invention is to obtain the geometric shape information of the two mating surfaces, which can be obtained by using the detection equipment to measure the two assembly surfaces; the second step is to obtain the initial contact point and the initial contact surface equation, and the mating surface can be firstly obtained through a clustering algorithm Convex hull contour, then calculate the convex hull radius and center point, and finally calculate and obtain; the third step is to establish the contact model, that is, establish the objective function and constraint conditions, and obtain it by establishing the force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com