ECT-based dual-array sensor system with adjustable duty ratio

A dual-array, sensor technology, applied in the direction of material capacitance, etc., can solve the problems of inability to obtain reconstructed images, inability to select duty cycle, inability to isolate electrodes embedded in insulating pipes, etc., and achieve high-quality and strong feasibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

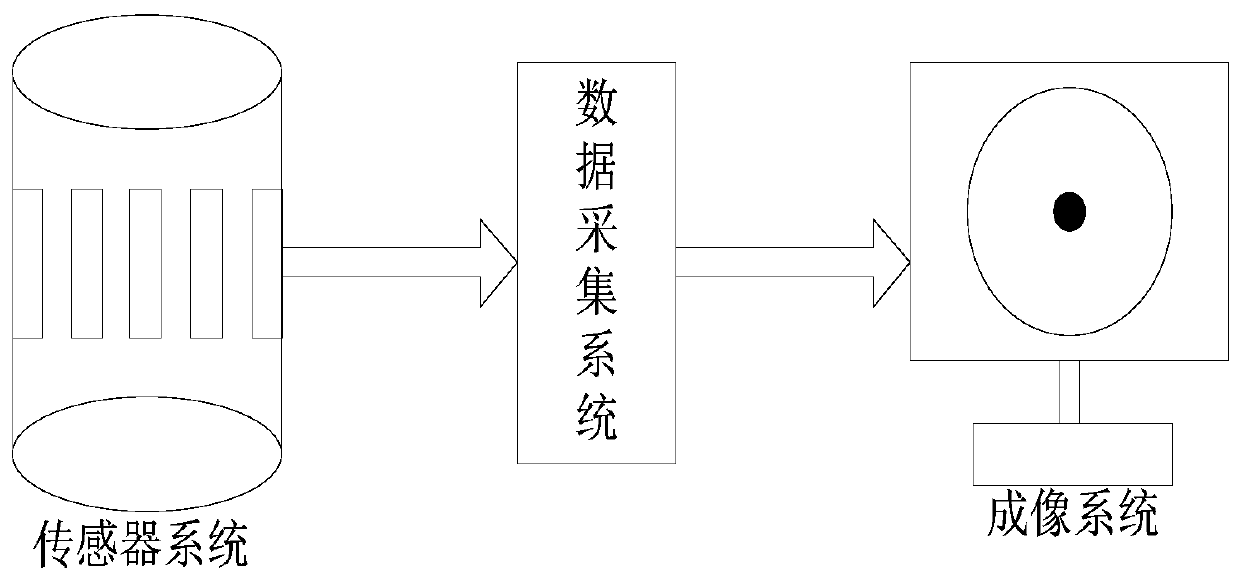

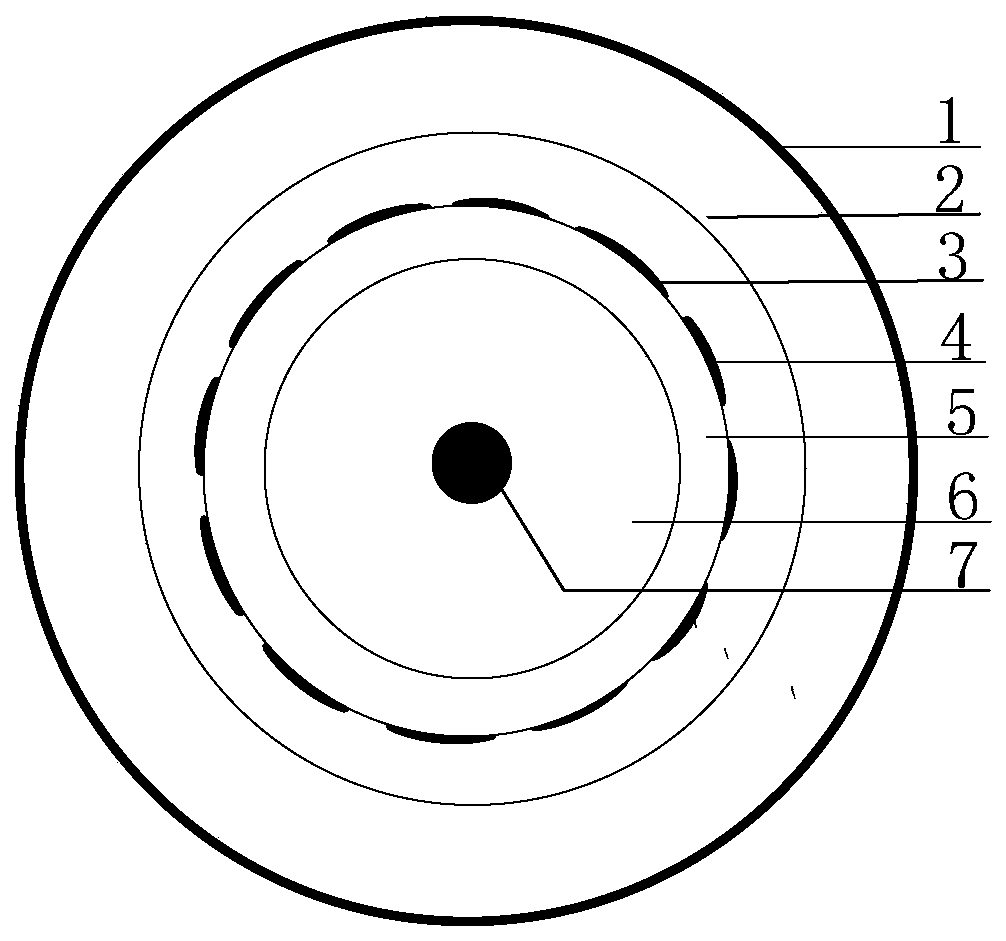

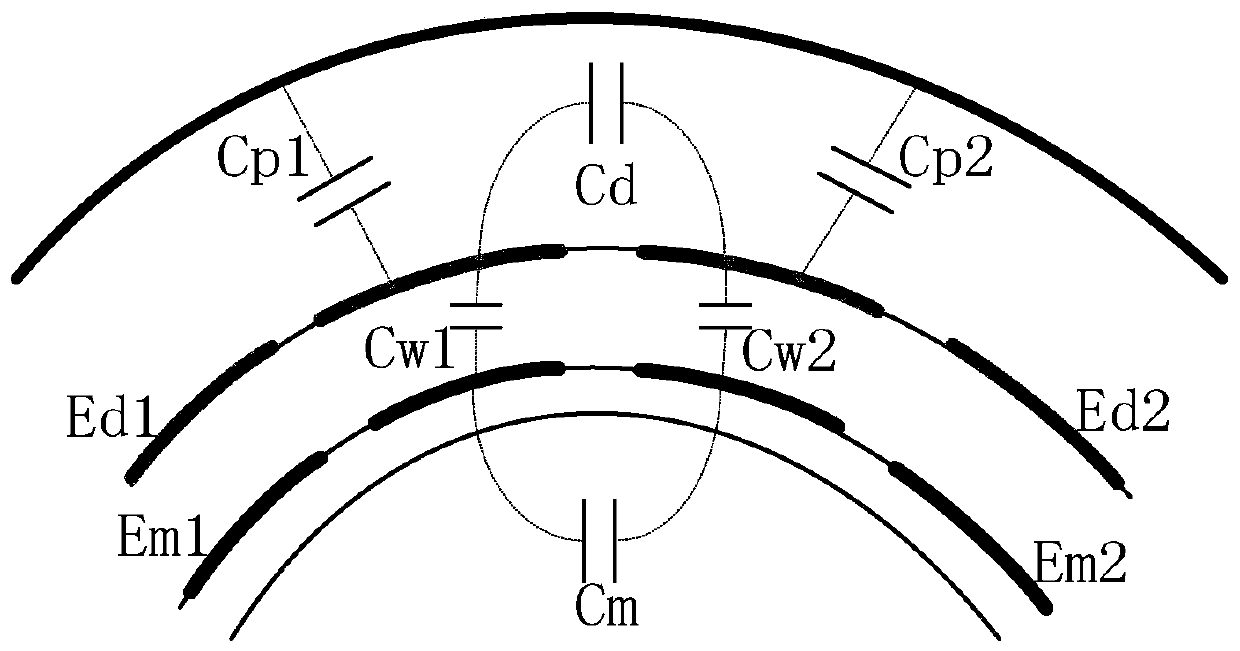

[0019] Such as figure 1 , figure 2 As shown, the ECT-based dual-array sensor system with adjustable duty cycle provided by the present invention includes a shielding cover 1, a plurality of differential electrodes 2, a plurality of measurement electrodes 3 and an adjustable support; wherein, the plurality of measurement electrodes 3 are installed in an annular manner at intervals on the outside of the outer circumferential surface of the pipeline 4; multiple differential electrodes 2 are installed on the outside of multiple measuring electrodes 3 through adjustable brackets, and each differential electrode 2 is connected to a measuring electrode The position of 3 is corresponding and the measuring electrode 3 and the differential electrode 2 are set concentrically; the differential electrode 2 and the measuring electrode 3 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com