Active portable welding joint intelligent detector

A detector and portable technology, which is applied in the field of active portable intelligent weld detectors, can solve the problems of difficult welding of structural parts, large ultrasonic emission, and large electromagnetic pollution, and achieve the effects of light weight, uniform heating, and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

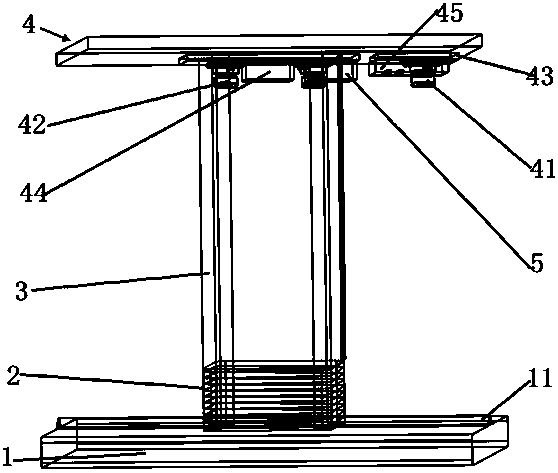

[0030] Such as figure 1As shown, this embodiment provides an active portable intelligent detector for welds. The intelligent detector includes an active heat source 2 located above the position of the weld 11 of the welding workpiece 1. The upper part of the active heat source 2 is connected to the information through the installation bracket 3. The detection and processing unit 4, the mounting bracket 3 in this embodiment is a rectangular bracket, and the power supply module 5 is respectively connected to the active heat source 2 and the information detection and processing unit 4 to provide power to the active heat source 2 and the information detection and processing unit 4 , the information detection and processing unit 4 includes an array infrared temperature detection module 41 for detecting the temperature of the weld and a visible light and depth camera module 42 for detecting the luminosity and depth of the weld, and the information processing module 43 is connected wi...

Embodiment 2

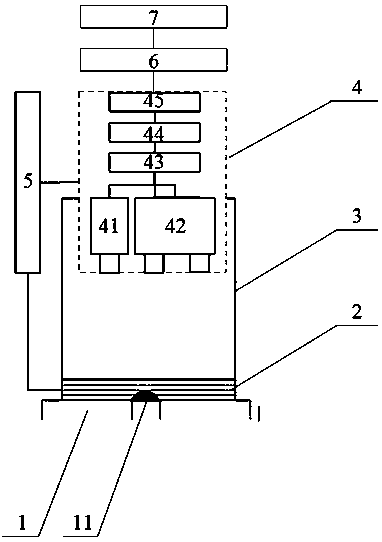

[0039] Such as figure 2 As shown, this embodiment provides an active portable intelligent detector for welds. The intelligent detector includes an active heat source 2 located above the position of the weld 11 of the welding workpiece 1. The upper part of the active heat source 2 is connected to the information through the installation bracket 3. The detection and processing unit 4, the power supply module 5 are respectively connected with the active heat source 2, the information detection and processing unit 4 to provide power to the active heat source 2, the information detection and processing unit 4, the information detection and processing unit 4 includes The array type infrared temperature detection module 41 of the seam temperature and the visible light and depth camera module 42 used to detect the luminosity and depth of the weld seam, the information processing module 43 is respectively connected with the array type infrared temperature detection module 41, the visib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com