Bit diameter measuring device

A technology for measuring device and drill bit diameter, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of low detection efficiency and high cost of manual detection, and achieve the effect of strengthening production automation, improving production efficiency and market competition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

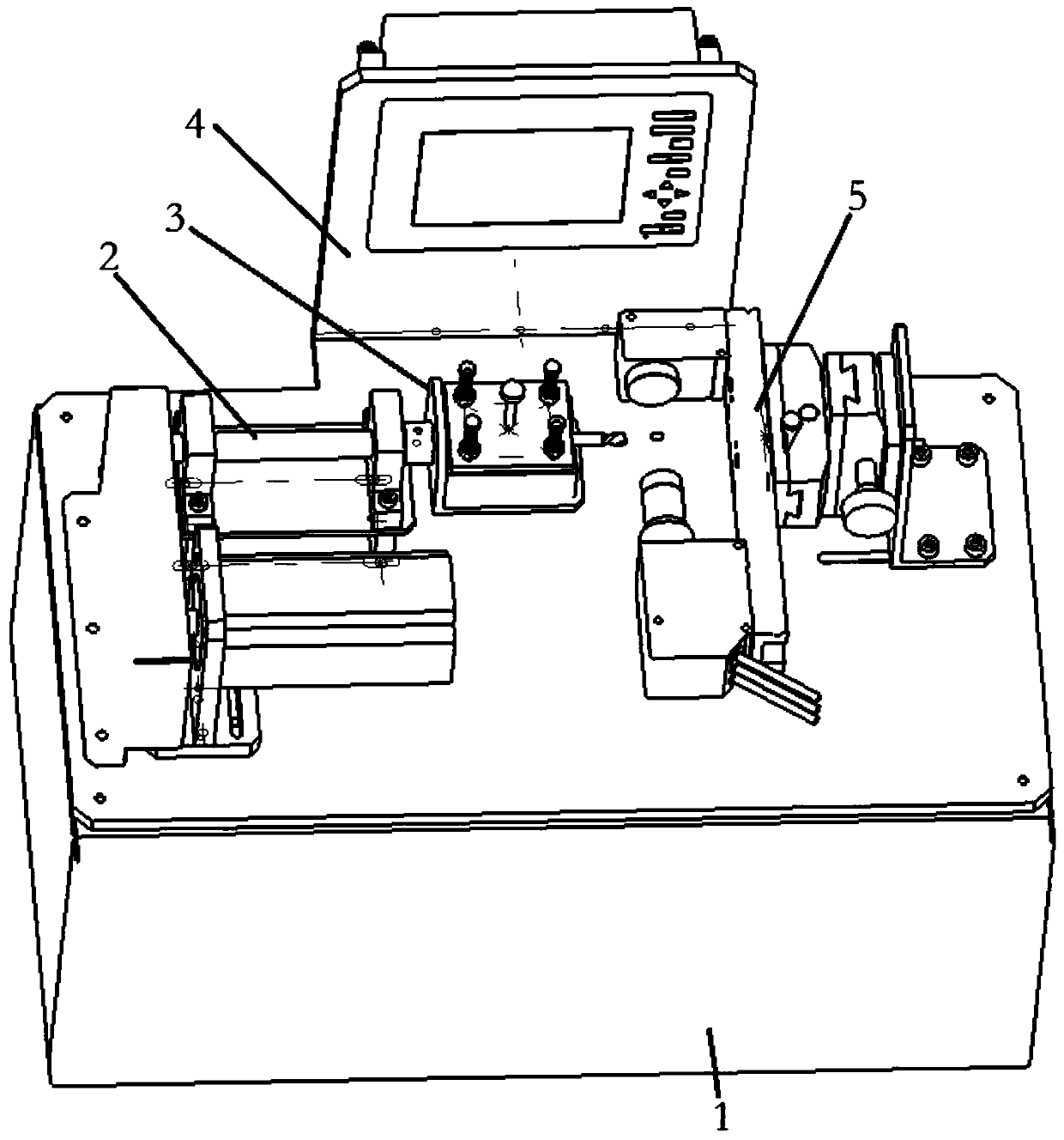

[0016] Embodiment: a kind of drill bit diameter measuring device.

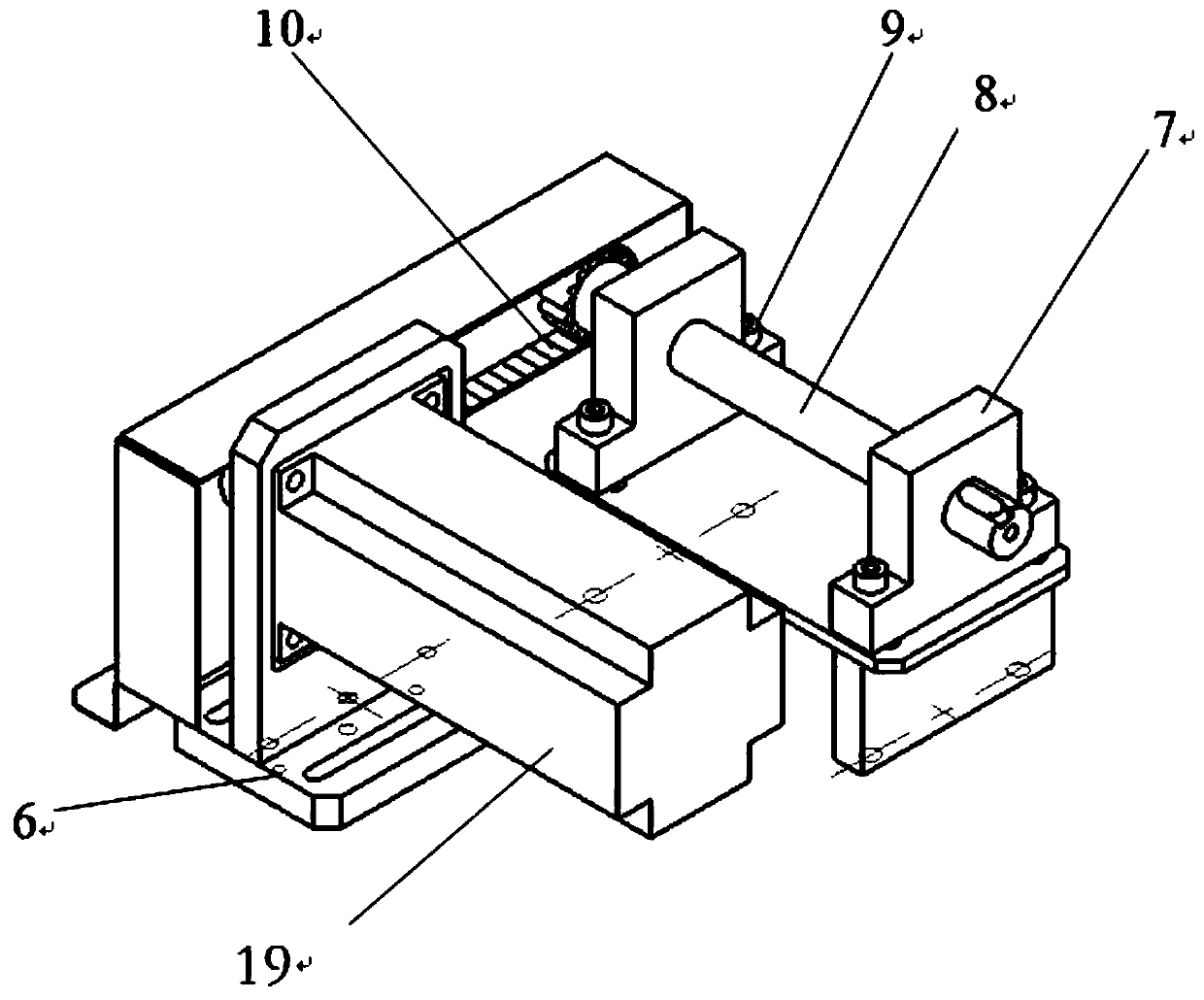

[0017] A drill bit diameter measuring device, comprising a base plate 1, a power mechanism 2, a pressing mechanism 3, a controller display screen 4 and a measuring mechanism 5, and the power mechanism 2, the pressing mechanism 3, the control display screen and the measuring mechanism 5 are all installed On the bottom plate 1, the power mechanism 2 includes a servo motor 19, a flat backing plate 6, a bearing seat 7, a transmission shaft 8, a gasket, a column fixing block and a synchronous belt 10, and the flat backing plate 6 is fixed on the bottom plate 1 There is a motor mounting bracket, the servo motor 19 is installed in the motor mounting bracket, one side of the synchronous belt 10 is installed on the shaft end of the servo motor 19, and the other side is installed on the shaft end of the transmission shaft 8, which is responsible for The power of the servo motor 19 is transmitted to the transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com