Novel tooth-connected type elastic bearing bush

An elastic shaft, a new type of technology, applied in the direction of couplings, couplings with safety disconnection joints, bearing components, etc., can solve the problems of motor burnt damage, inability to rotate, driven shaft stuck, etc., to achieve vibration Small, practical, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following describes the present invention through specific implementation cases shown in the drawings. However, these descriptions are only an example, and are not intended to limit the scope and limitations of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessary obscurity or misunderstanding of the concept of the present invention.

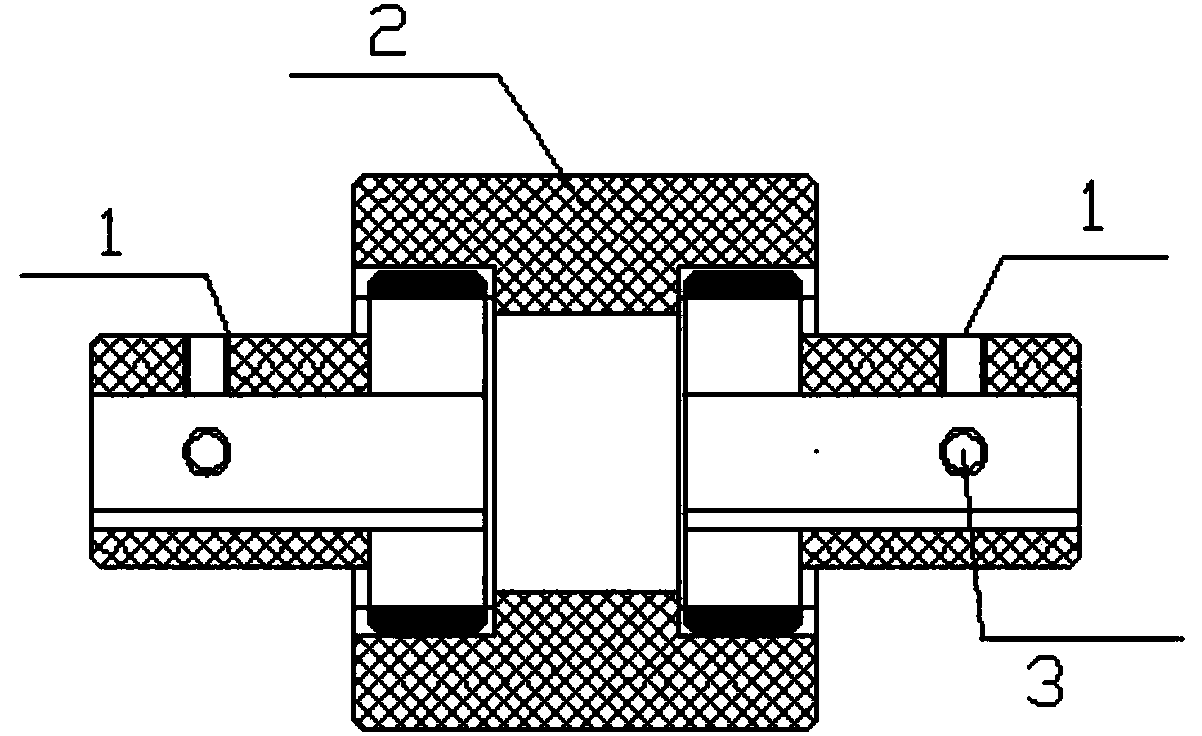

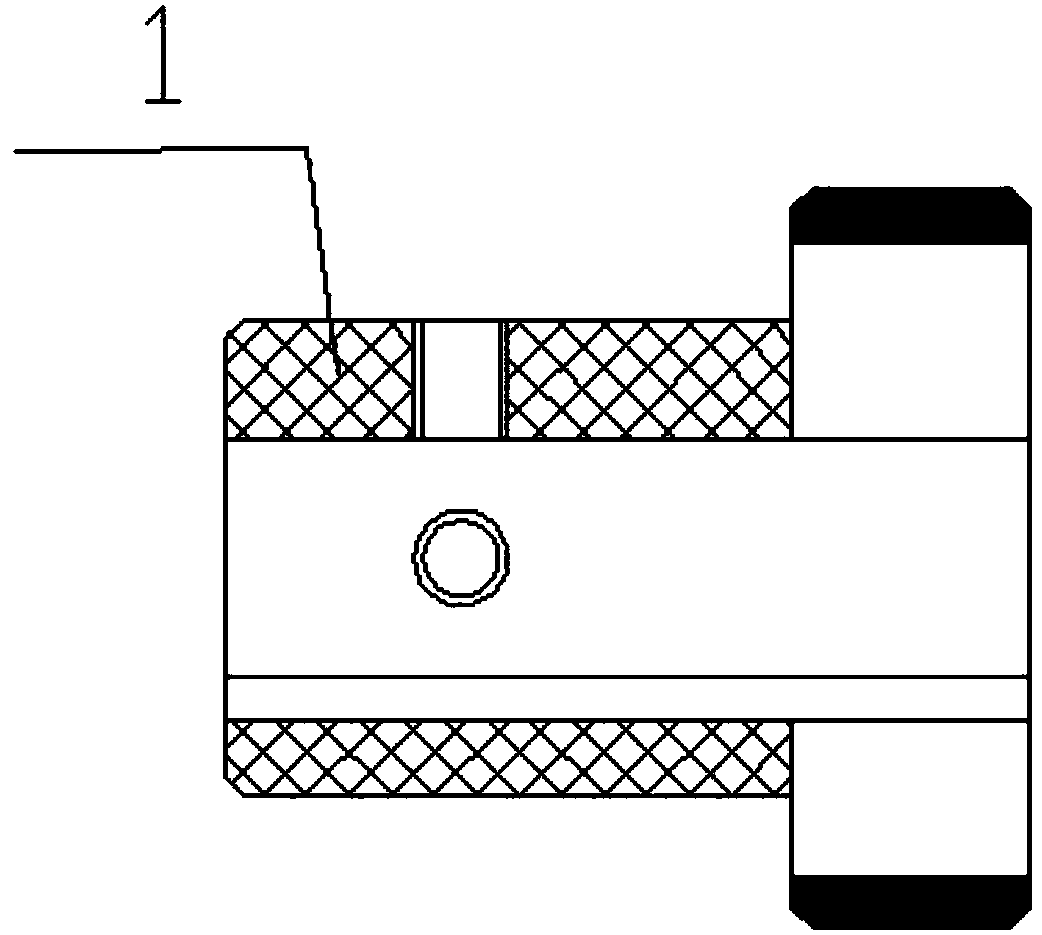

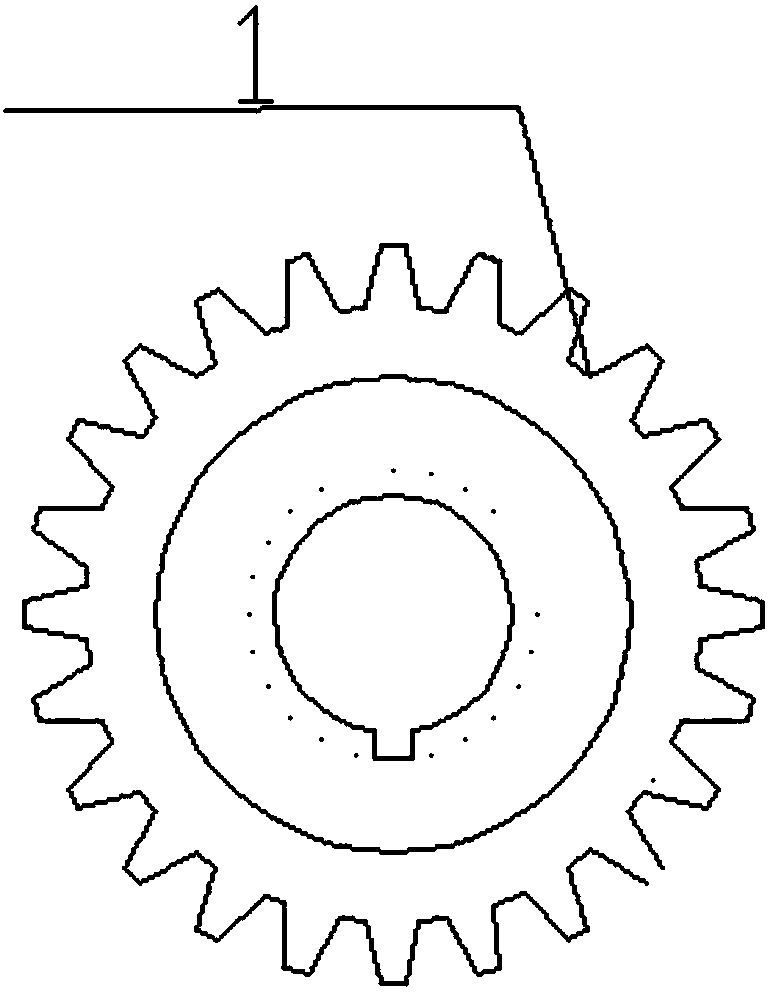

[0017] Such as figure 1 As shown in --6, this specific implementation adopts the following technical solutions: it contains a connecting shaft 1, a nylon gear sleeve 2, a set screw 3; the complete set of bearing shells have two connecting shafts, a nylon gear sleeve, and four set screws . The two ends of the connecting shaft 1 are respectively provided with four set screws 3 opposite to each other, the inner hole of the connecting shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com