Oil injector and engine

A fuel injector and fuel injector technology, which is applied to machines/engines, engine components, mechanical equipment, etc., can solve problems affecting the opening and closing of the fuel injector valve core, leakage, and changes in fuel injector volume, so as to prevent accidents from happening. Source, high efficiency, and the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

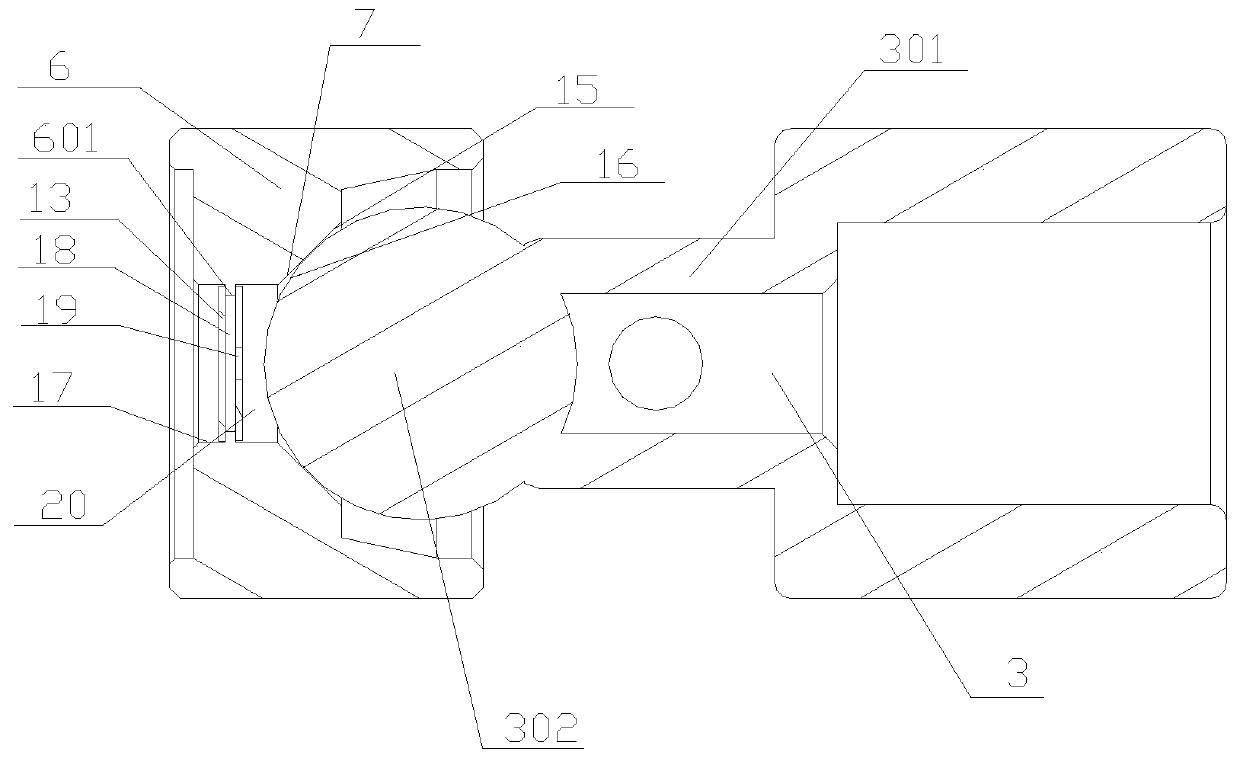

[0034] like Figure 1 to Figure 4 As shown, a fuel injector includes a fuel injector 2, a valve core assembly 3, a valve seat 6 and a first baffle 13. The fuel injector 2 is provided with a fuel injection hole 4, and the valve core assembly 3 It includes a valve core 301 and a sealing ball 302 connected together, the sealing ball 302 is used to seal the oil injection hole 4, and the valve seat 6 is arranged in the oil injection nozzle 2 near the end of the oil injection hole 4 , the valve seat 6 and the sealing ball 302 form an oil passage 17 along the direction that the sealing ball 302 approaches the oil injection hole 4, the first blocking piece 13 is fixedly arranged in the oil passage 17, and It includes a second baffle 19, the second baffle 19 is arranged in the oil passage 17, and both the first baffle 13 and the second baffle are in sealing connection with the valve seat 6;

[0035] The second blocking piece 19 is arranged on the side of the first blocking piece 13 cl...

Embodiment 2

[0048] Embodiment 2: be the preferred embodiment of embodiment 1,

[0049] like Figure 1 to Figure 4 Shown: a fuel injector,

[0050] Comprising a fuel injection nozzle 2, a valve core assembly 3, a valve seat 6 and a first stopper 13, the fuel injection nozzle 2 is provided with an oil injection hole 4, and the valve core assembly 3 includes a valve core 301 and a A sealing ball 302, the sealing ball 302 is used to seal the fuel injection hole 4, the valve seat 6 is arranged in the fuel injection nozzle 2 near the end of the fuel injection hole 4, the valve seat 6 and the The sealing ball 302 forms an oil passage 17 along the direction that the sealing ball 302 is close to the oil injection hole 4, the first blocking piece 13 is fixedly arranged in the oil passage 17, and also includes a second blocking piece 19, the The second blocking piece 19 is arranged in the oil passage 17, and both the first blocking piece 13 and the second blocking piece are in sealing connection w...

Embodiment 3

[0081] Embodiment 3: be the preferred embodiment of embodiment 2

[0082] The difference with embodiment 1 is:

[0083] Both the first baffle 13 and the second baffle 19 are welded and hermetically connected to the raised portion 601 on the valve seat 6;

[0084]Preferably, the first blocking piece 13 and the second blocking piece 19 are respectively sealed and welded to the left and right sides of the raised portion 601, so that the first blocking piece 13, the second blocking piece 19 and the raised portion 601 form a buffer condensation chamber 18. The overflow cavity 20 is formed by the second blocking plate 19, the inner wall of the oil passage 17 and the sealing ball 302.

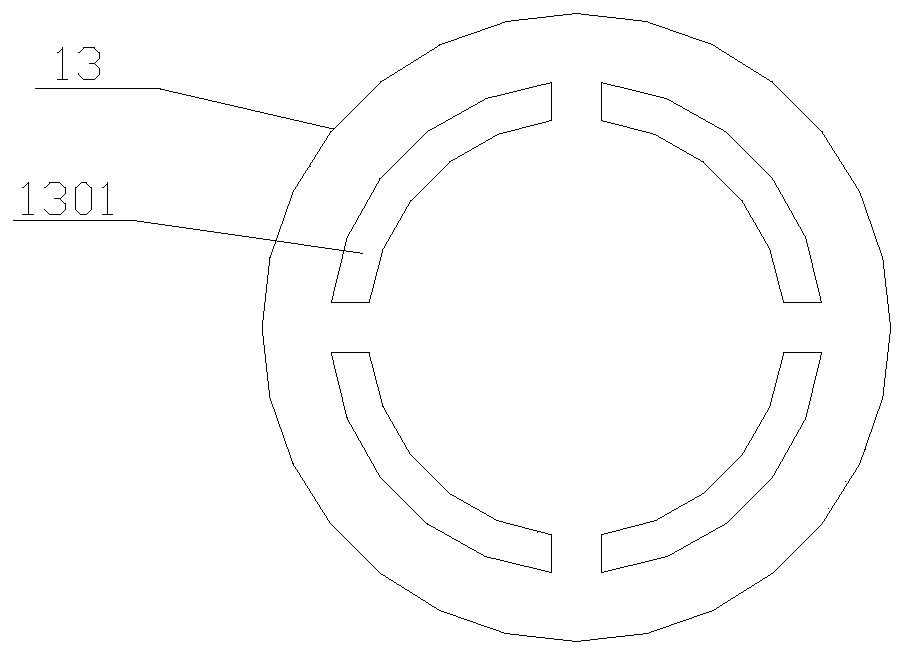

[0085] like figure 2 As shown, the injection hole 1301 on the first blocking plate 13 is an arc-shaped hole around the center of the first blocking plate 13;

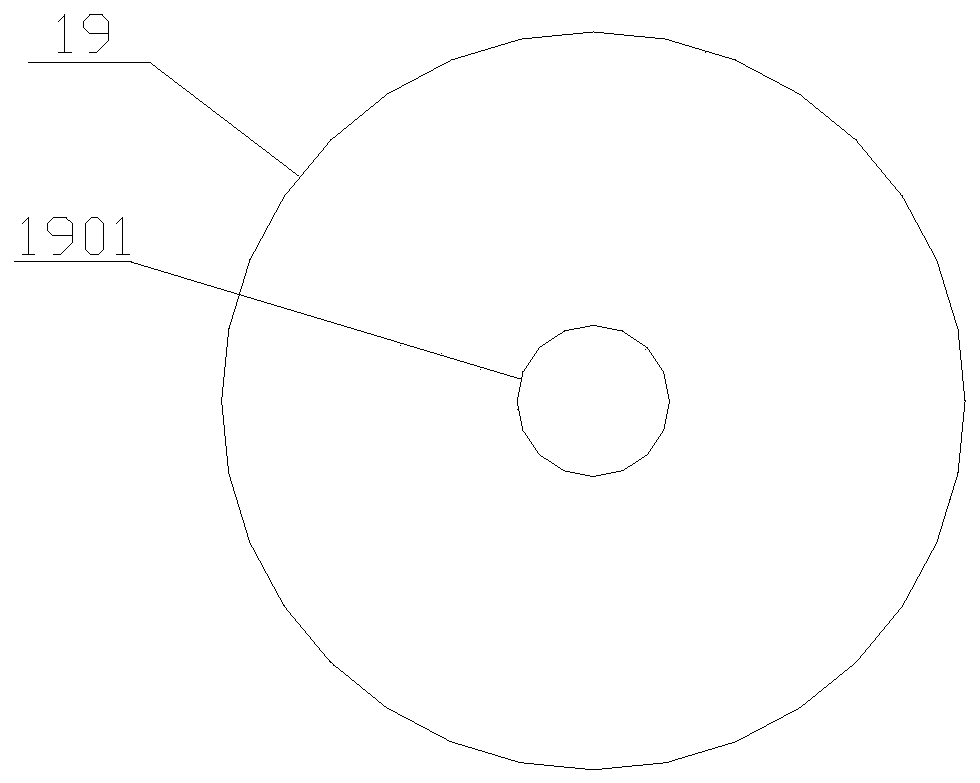

[0086] like image 3 As mentioned above, the opening 1901 in the center of the second blocking piece 19 is a circular hole;

[0087] Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com