Groove connected repairable low-yield point steel damper

A low-yield point steel and groove connection technology is applied in the field of repairable low-yield point steel dampers, which can solve the problems of energy-consuming dampers that cannot be put into use again, poor repairability, etc., and achieves diversification of energy-consuming parts, The effect of strong energy consumption and shock absorption and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

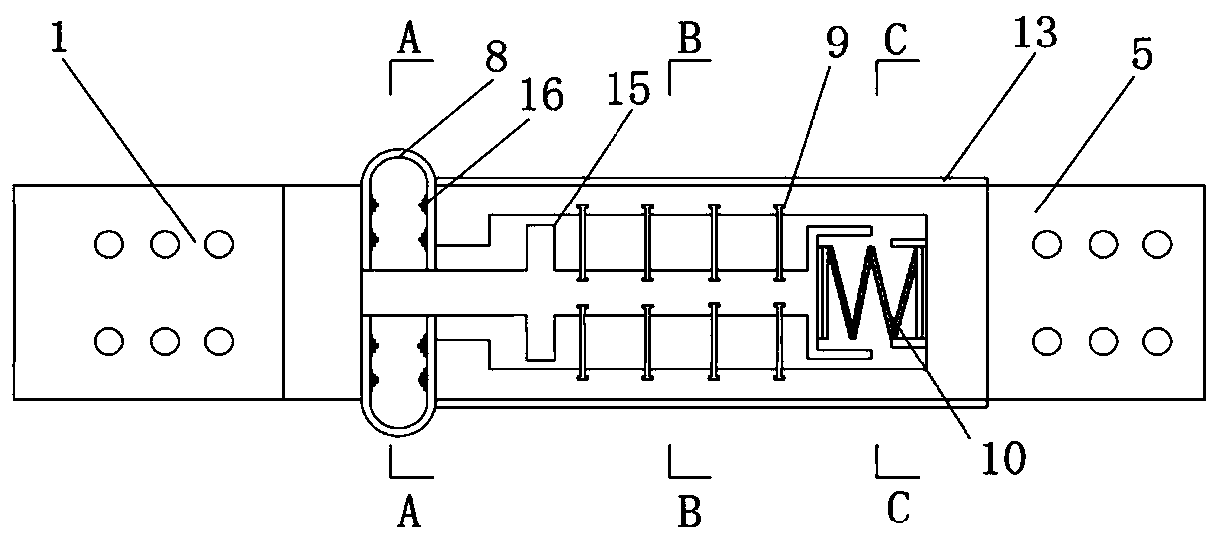

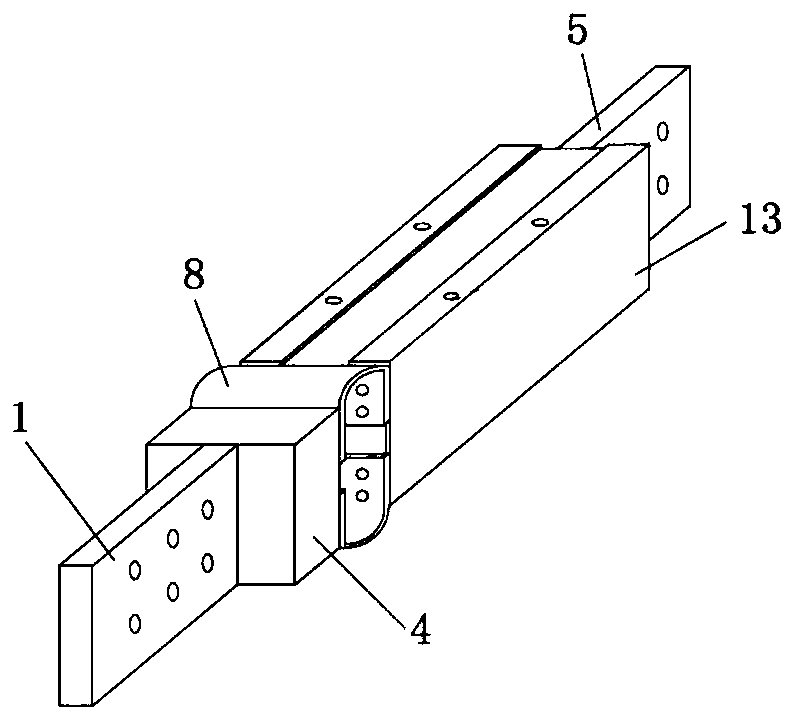

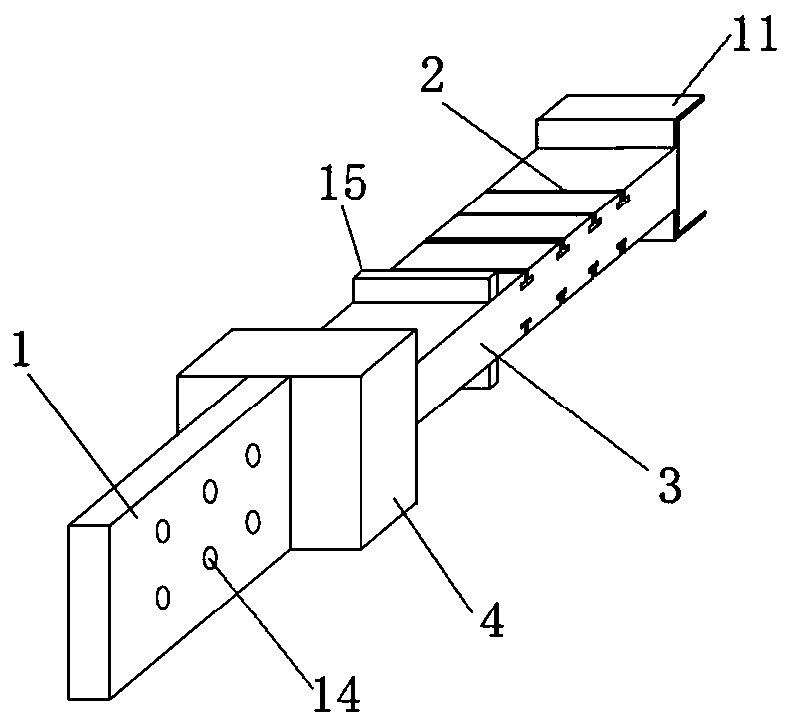

[0019] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] The damper of the invention is suitable for energy dissipation supports and connections in building structures. Such as Figure 1 to Figure 4 As shown, the damper includes a sliding guide rod and a protective case for protecting the sliding guide rod.

[0021] Wherein, the sliding guide rod includes a guide rod connection part 1 connected with a building structure at one end, an energy consumption part connection part 3 with a T-shaped groove 2, and connecting the guide rod connection part 1 and the energy consumption part connection part 3 together. The connected connecting block 4; the T-shaped groove 2 of the connecting part 3 of the sliding guide rod energy-consuming part includes the T-shaped groove 2 arranged on the upper surface of the connecting part 3 of the sliding guide rod energy-consuming part and the T-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com