A kind of smart sweat acid-base color-changing clothing

A technology for fabrics and concentrates, applied in the field of intelligent sweat acid-base discoloration clothing, can solve the problems of the acid-base discoloration indicator cannot be used repeatedly, the acid-base indication range is small, the application range is limited, etc. , the effect of rapid color change, reversible pH color change and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for dyeing clothing with intelligent sweat acid-base discoloration, comprising the following steps:

[0043] 1) Pre-dyeing treatment: soak the cotton fabric or cotton label sample in dimethyl sulfoxide (DMSO) solution at room temperature for 1 hour before dyeing.

[0044] 2) Dyeing:

[0045] Dyeing formula: Benthic algae natural raw material concentrate is 2% relative to the weight of the fabric; dimethyl sulfoxide; NaHCO3 / Na2CO3 buffer solution with pH=8;

[0046] When dyeing, select 2% benthic algae natural raw material concentrate relative to the fabric weight, mix the soaking solution (DMSO) and water one to one as the dyeing solution, control the bath ratio at 1:30, and combine it with ultrasonic waves (300W, 26KHZ) To achieve mordantless dyeing, the temperature is 45°C, and the dyeing time is 30min. After that, the temperature was raised to 65°C at 2°C / min, and the NaHCO3 / Na2CO3 buffer solution was added twice, the pH was controlled at 8, and the color ...

Embodiment 2

[0053] A method for dyeing clothing with intelligent sweat acid-base discoloration, comprising the following steps:

[0054] 1) Pre-dyeing treatment: Before dyeing, after winding the cotton yarn according to the density of 0.33g / cm3, because the pressure between the yarns is tighter than that of the fabric, fully soak the yarn in dimethyl sulfoxide (DMSO) solution for one hour Two hours, during which ultrasonic vibrations are used to promote yarn expansion.

[0055] 2) Dyeing:

[0056] Dyeing formula: Benthic algae natural raw material concentrate is 2% relative to the weight of the fabric; NaHCO with pH=8 3 / Na 2 CO 3 buffer solution;

[0057] When dyeing, take 2% benthic algae natural raw material concentrate relative to the weight of the fabric, mix the soaking solution (DMSO) and water one to one as the dyeing solution, and the bath ratio is 1:30. Put the cheese dyeing machine at room temperature for dyeing, adjust the cheese dyeing machine to start dyeing from the po...

Embodiment 3

[0064] 1) Printing:

[0065] Dye formula: 2% benthic algae natural raw material concentrate relative to the weight of the fabric, 5% mordant, 4% urea, 2% ammonium sulfate, mix with water, stir to fully dissolve, then add paste (sodium alginate and synthetic dragon Glue 1:1 mixed with 40% solid content paste) and fully stirred in a beaker for two hours for later use.

[0066] Print the clothes, dry at 60°C for 10 minutes, and steam at 105°C for 15 minutes.

[0067] 2) Post-processing: ① Drain after dyeing → ② Rinse with cold water to remove undyed dye → ③ Soap (85℃×20min, soap flakes 2g / L) to remove floating color and increase gloss → ④ Wash with water → ⑤ Dry at 60℃ Dry.

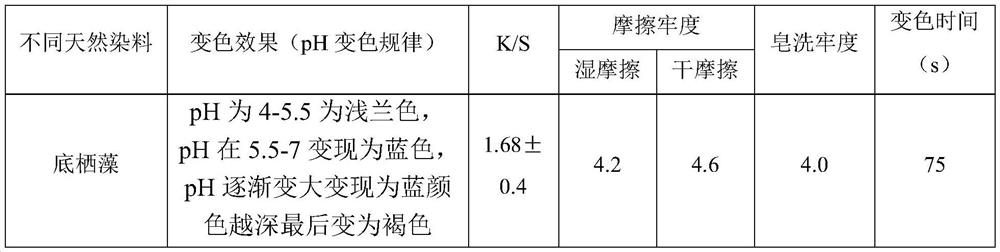

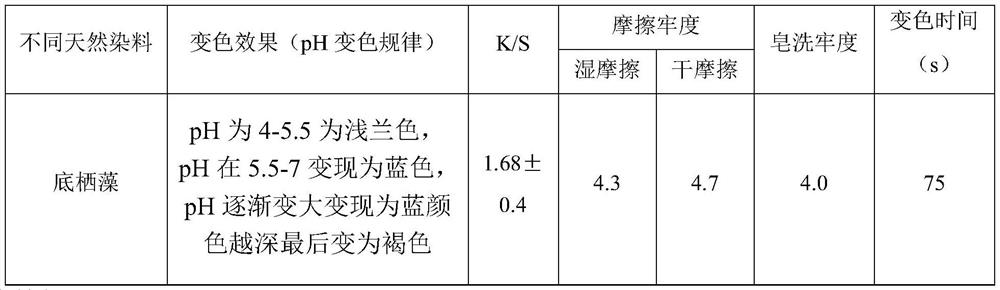

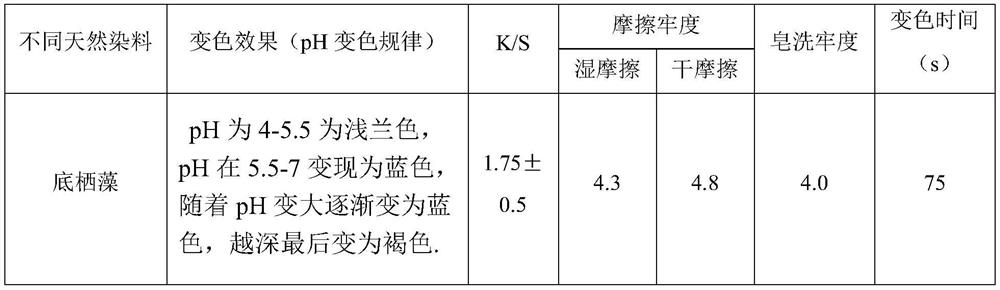

[0068] The discoloration effect of the resulting printed clothes is shown in Table 3.

[0069] Table 3 The discoloration effect of the clothes printed with benthic algae natural dyes

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com