A fly ash composite phase change material wall and a solar greenhouse with it

A composite phase change material and a technology of phase change materials, which are applied in the fields of fly ash composite phase change material walls and solar greenhouses, can solve the problems of non-compliance with national environmental protection industrial policies, unsatisfactory effects, consumption of fuel and resources, etc. Achieve the effect of solving the degradation problem of thermophysical properties, reducing easy leakage from the substrate, and solving the problem of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

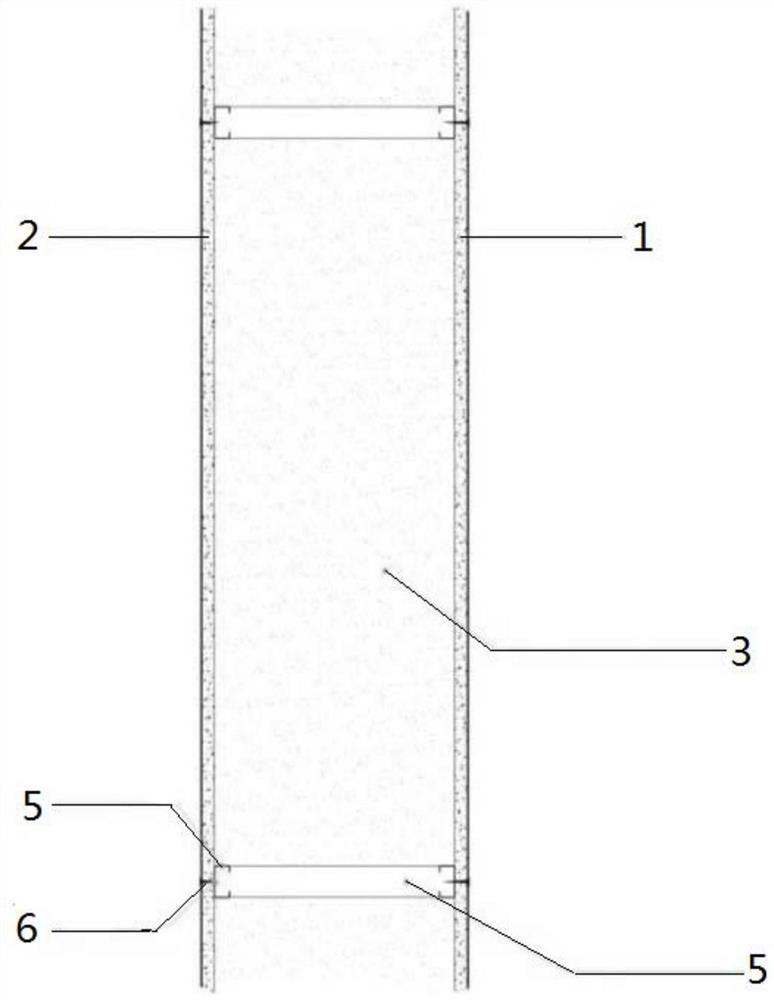

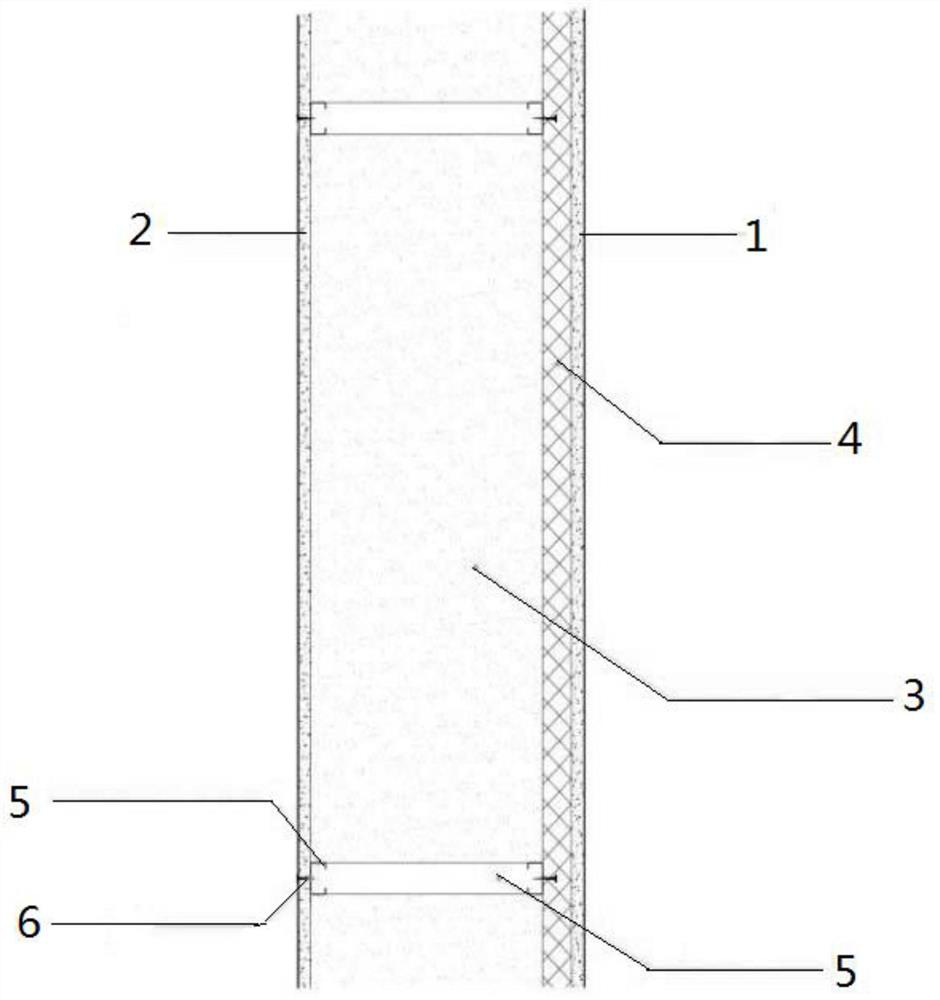

[0061] The fly ash composite phase change material wall, including the inner wall 1, the outer wall 2 and the phase change material layer 3 between the inner wall 1 and the outer wall 2, the inner wall 1 and the outer wall 2 are made of light H-shaped steel 5 for structural connection, light H-shaped steel 5 and inner wall 1 and outer wall 2 are fixed with self-tapping screws; inner wall 1 and outer wall 2 are 9-12mm thick cement pressure plates;

[0062] The phase change material layer 3 is composed of the following raw materials: 50 kg of fly ash, 5 kg of Glauber's salt, 5 kg of paraffin phase change material, 20 kg of loess, and 3 kg of desulfurized gypsum.

[0063] The preparation method of the fly ash composite phase change material wall comprises the following steps:

[0064] (1) Take each raw material by the above weight;

[0065] (2) Mix water and Glauber's salt, fully stir and dissolve, then add 4kg of fly ash and stir and mix to obtain mixture A, for subsequent use;...

Embodiment 2

[0070] The fly ash composite phase change material wall, including the inner wall 1, the outer wall 2 and the phase change material layer 3 between the inner wall 1 and the outer wall 2, the inner wall 1 and the outer wall 2 are made of light H-shaped steel 5 for structural connection, light H-shaped steel 5 and inner wall 1 and outer wall 2 are fixed with self-tapping screws; inner wall 1 and outer wall 2 are built with 120mm thick machine-made red bricks;

[0071] The phase change material layer 3 is composed of the following raw materials: 65 kg of fly ash, 8 kg of sodium hydrogen phosphate dodecahydrate, 7 kg of paraffin-graphite composite phase change material, 30 kg of loess, and 5 kg of lime.

[0072] The preparation method of the fly ash composite phase change material wall comprises the following steps:

[0073] (1) Take each raw material by the above weight;

[0074] (2) water is mixed with sodium hydrogen phosphate dodecahydrate, fully stirred and dissolved, then t...

Embodiment 3

[0079] The fly ash composite phase change material wall, including the inner wall 1, the outer wall 2 and the phase change material layer 3 between the inner wall 1 and the outer wall 2, the inner wall 1 and the outer wall 2 are made of light H-shaped steel 5 for structural connection, light H-shaped steel 5 and inner wall 1 and outer wall 2 are fixed with self-tapping screws; inner wall 1 and outer wall 2 are built with 100mm thick lightweight blocks;

[0080] The phase change material layer 3 is composed of the following raw materials: 50 kg of fly ash, 8 kg of calcium chloride hexahydrate, 7 kg of fatty acid phase change material, 30 kg of loess, and 5 kg of phosphogypsum.

[0081] The preparation method of the fly ash composite phase change material wall comprises the following steps:

[0082] (1) Take each raw material by the above weight;

[0083](2) water is mixed with calcium chloride hexahydrate, fully stirred and dissolved, then the fly ash that adds 4kg is stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com