Soft shaft support device of glass bent tempering equipment

A support device and glass tempering technology, applied in glass tempering, glass manufacturing equipment, glass forming, etc., can solve problems such as deformation and affecting glass shape accuracy, and achieve the goals of improving forming accuracy, ensuring production quality, and avoiding deformation problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

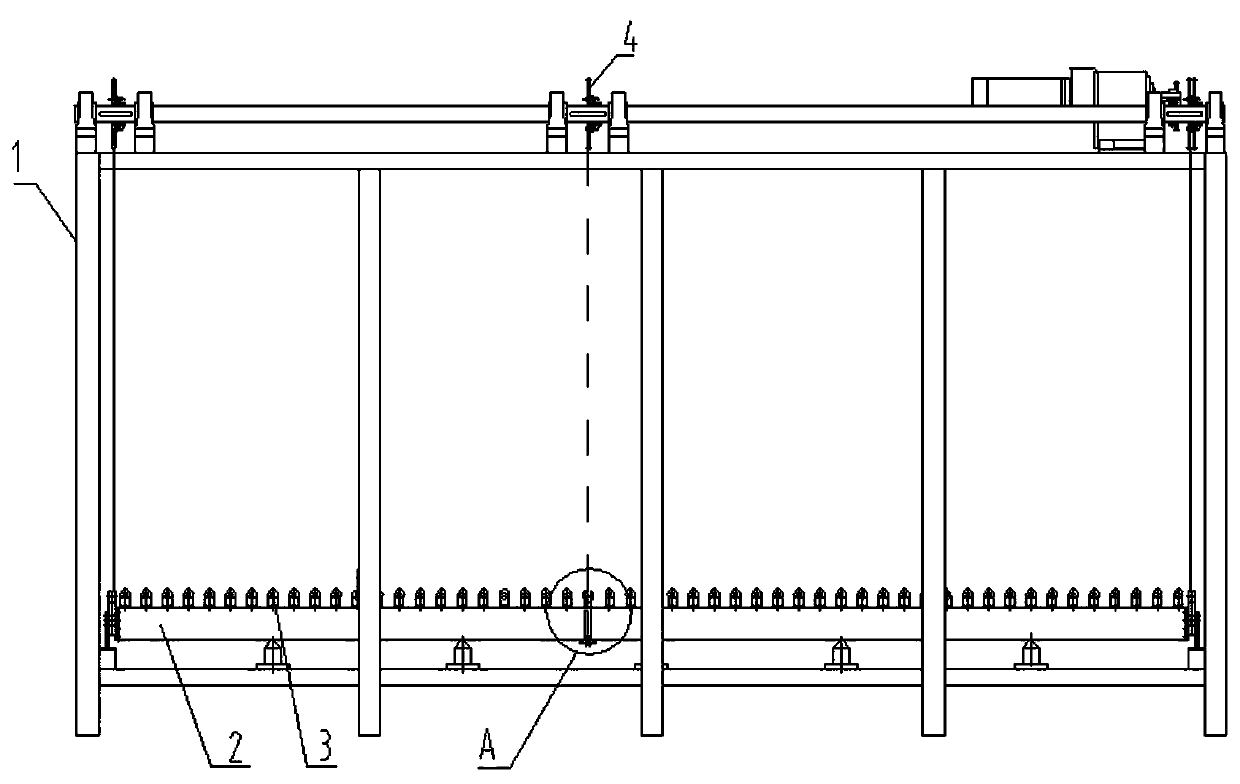

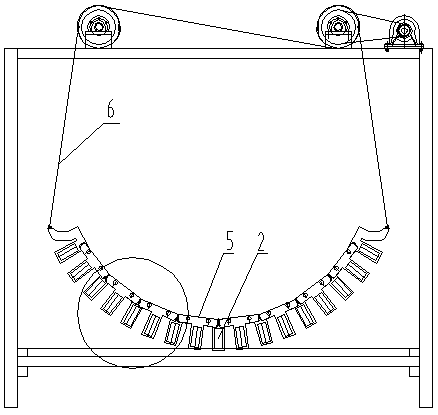

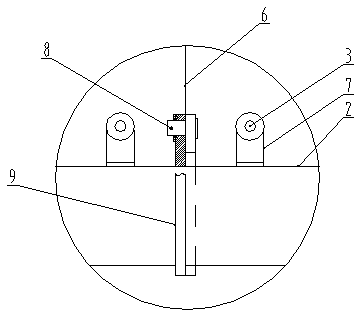

[0026] As shown in the figure, a flexible shaft support device for flexible shaft bending glass tempering equipment, which is installed on the flexible shaft bending glass tempering equipment, figure 1 , 2 Shown is flexible shaft bending glass tempering equipment, including frame 1, arc-changing mechanism 5, flexible shaft 3 and air grille. The air grille has square tubes 2 made of aluminum profiles, and multiple rows of square tubes 2 are arranged in parallel perpendicular to the direction of glass movement. The square tubes 2 on both sides are respectively provided with a plurality of flexible shaft supports 7 (see image 3 ), used to carry the flexible shaft 3, mostly arranged in parallel with the flexible shaft 3 and the axial direction of the flexible shaft 3 is perpendicular to the glass movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com