Main transportation equipment automatic control method based on mine coal production amount

An automatic control system and main transportation technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problem of automatic start, stop and speed regulation of belt conveyors, long-term idling, and coal piles and other issues to achieve the effect of realizing unmanned operation management, reducing safety hazards, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

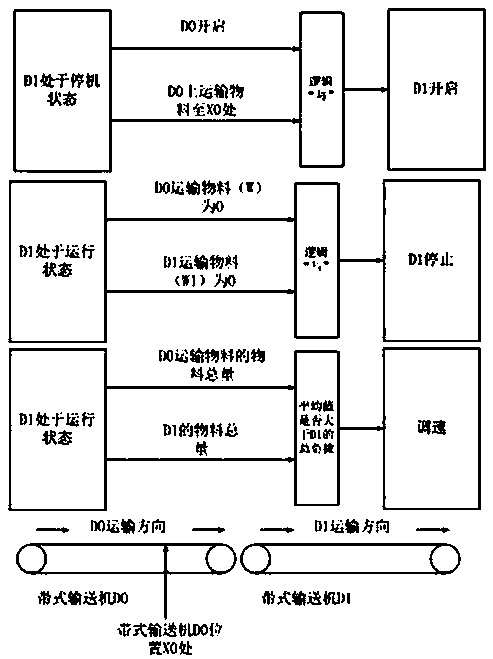

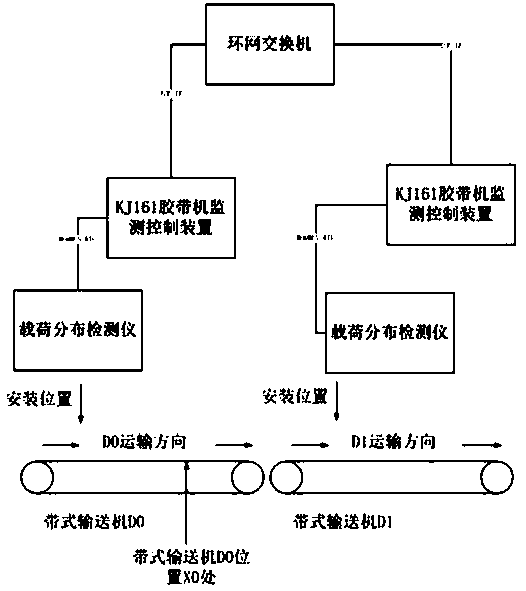

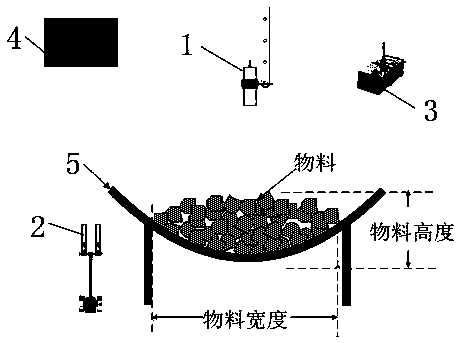

[0032] Such as Figure 1-3 As shown, the automatic control method of the main transportation equipment based on the amount of coal produced in the mine is characterized in that: for the belt conveyor D1 that constitutes the main transportation system of the coal mine, it is started by the belt conveyor D0 on the upstream belt conveyor that overlaps it. The position of the material is determined by X0. When the material is transported to X0, D1 starts; its stop is determined by the total amount of material transported by the upstream belt conveyor overlapping with it W and the total amount of material transported by itself W1, when W=W1=0 , D1 stops; its transportation speed is determined by the output and the total amount of transportation on the current transportation line. If the current output is Wc1, the total upstream transportation volume of D1 is Wc2, and the maximum transportation volume of D1 is Wt (transportation volume per hour), per second The transportation volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com