An installation vehicle for a turbofan aircraft engine

A technology for aircraft engines and installation vehicles, which is applied to lifting devices, workbenches, manufacturing tools, etc., and can solve problems such as inability to lock the lifting mechanism, inconvenient adjustment of engine pitch angle and deflection angle, and potential safety hazards of the engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

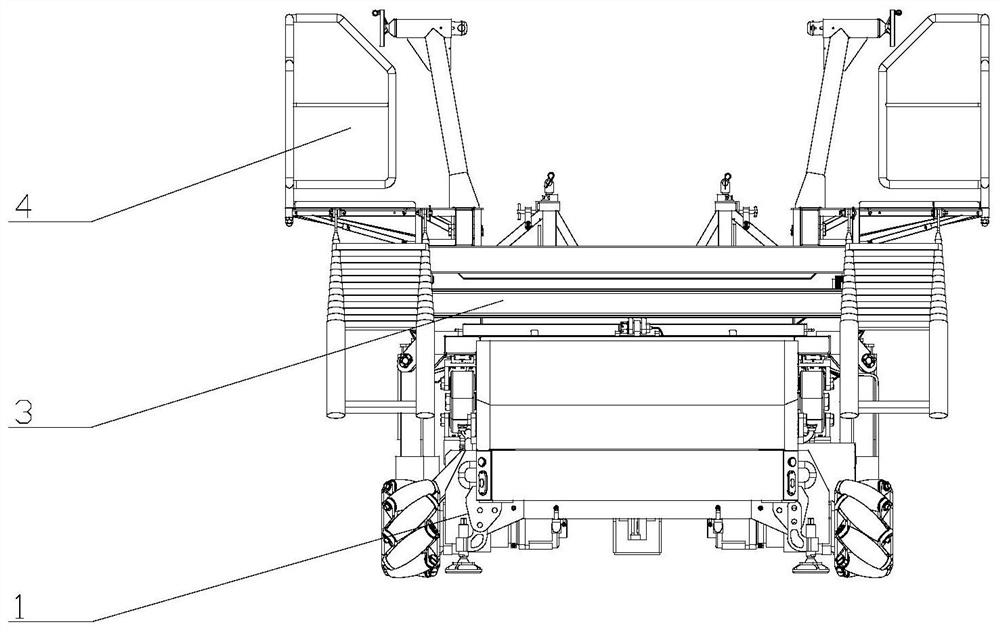

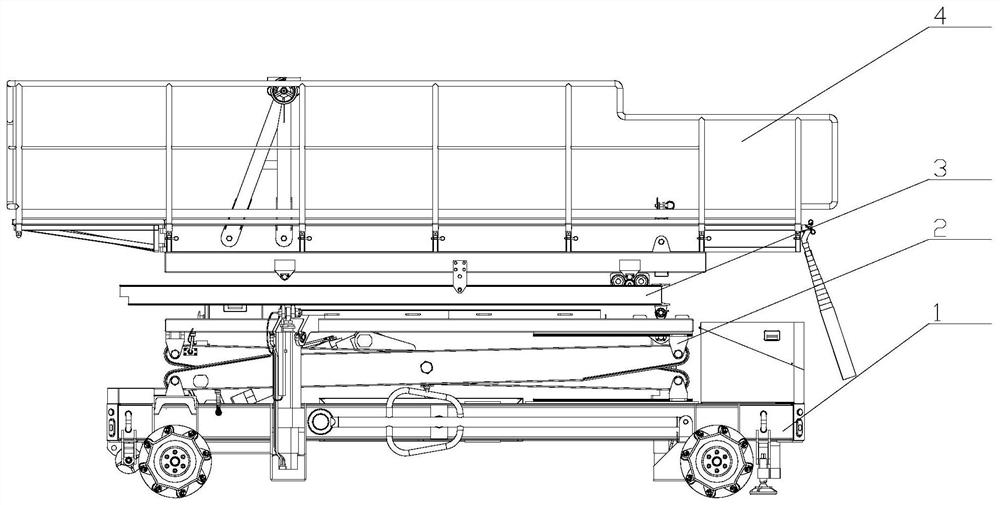

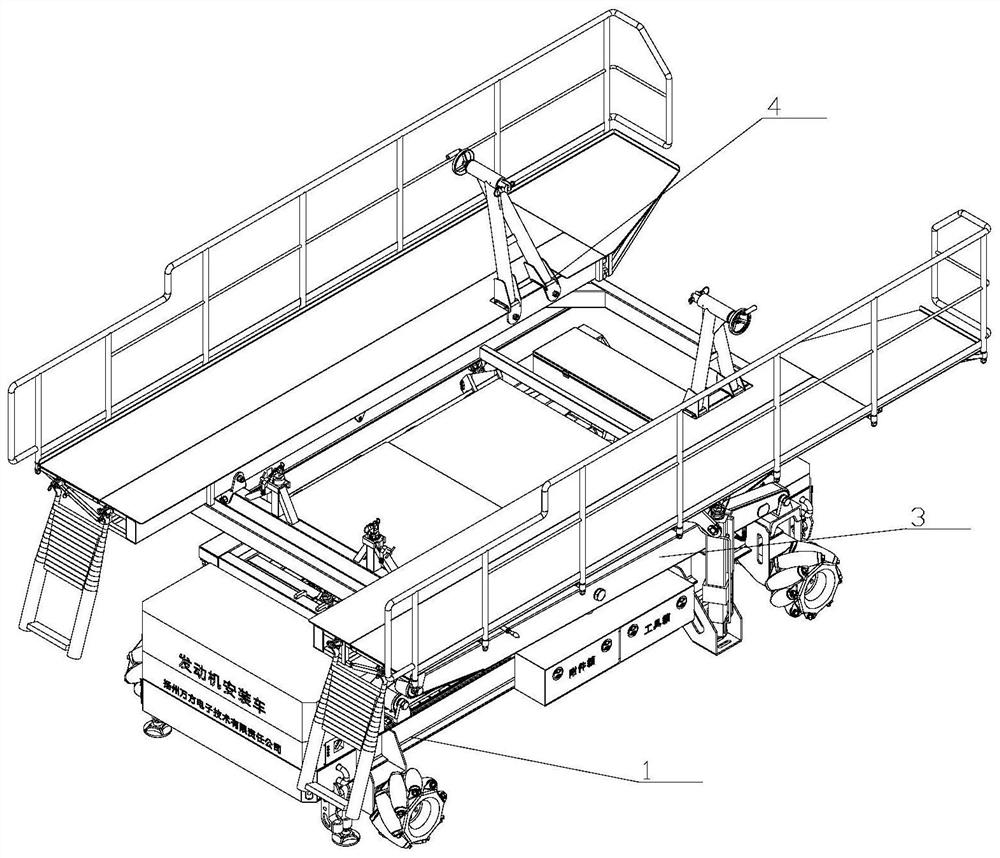

[0048] The present invention is as Figure 1-22 As shown, it includes a chassis assembly 1, a lifting assembly 2, a turning assembly 3 and a working platform 4; the chassis assembly 1 includes a frame 11 and a number of Mecanum wheels 12 connected to the frame 11, and the lifting assembly 2 is connected On the frame 11, the turning assembly 3 is connected to the lifting assembly 2, and the working platform 4 is connected to the turning assembly 3;

[0049] The lifting assembly 2 includes a lifting platform 21 (in actual implementation, the lifting platform can be processed into a frame shape as shown in the drawings, thereby reducing the operating load and production cost of the equipment), at least one outer scissor arm 22, and at least one inner scissor fork. Arm 23, at least one linear drive device 24 and at least one safety lock 25, the lifting platform 21 is horizontally arranged above the frame 11, the bottom surface of the lifting platform 21 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com