Folding type chip removal machine and control method thereof

A control method and technology of a chip conveyor, which are applied in the directions of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of poor work stability, low separation efficiency, and large floor space, and achieve a small floor space. , The effect of high conveying efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

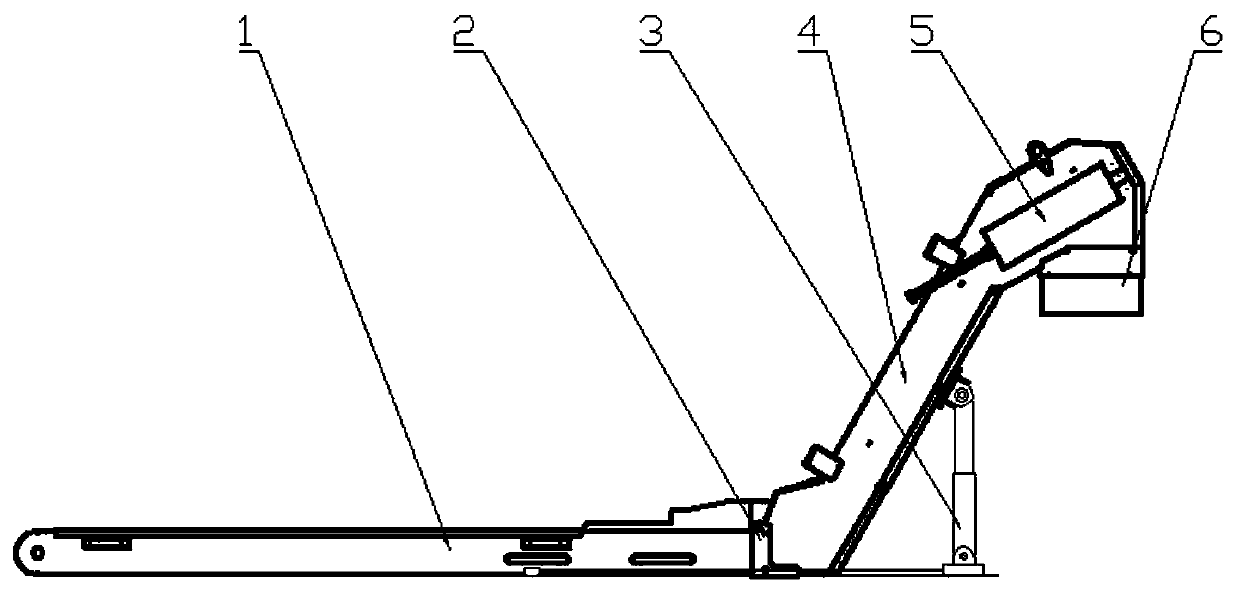

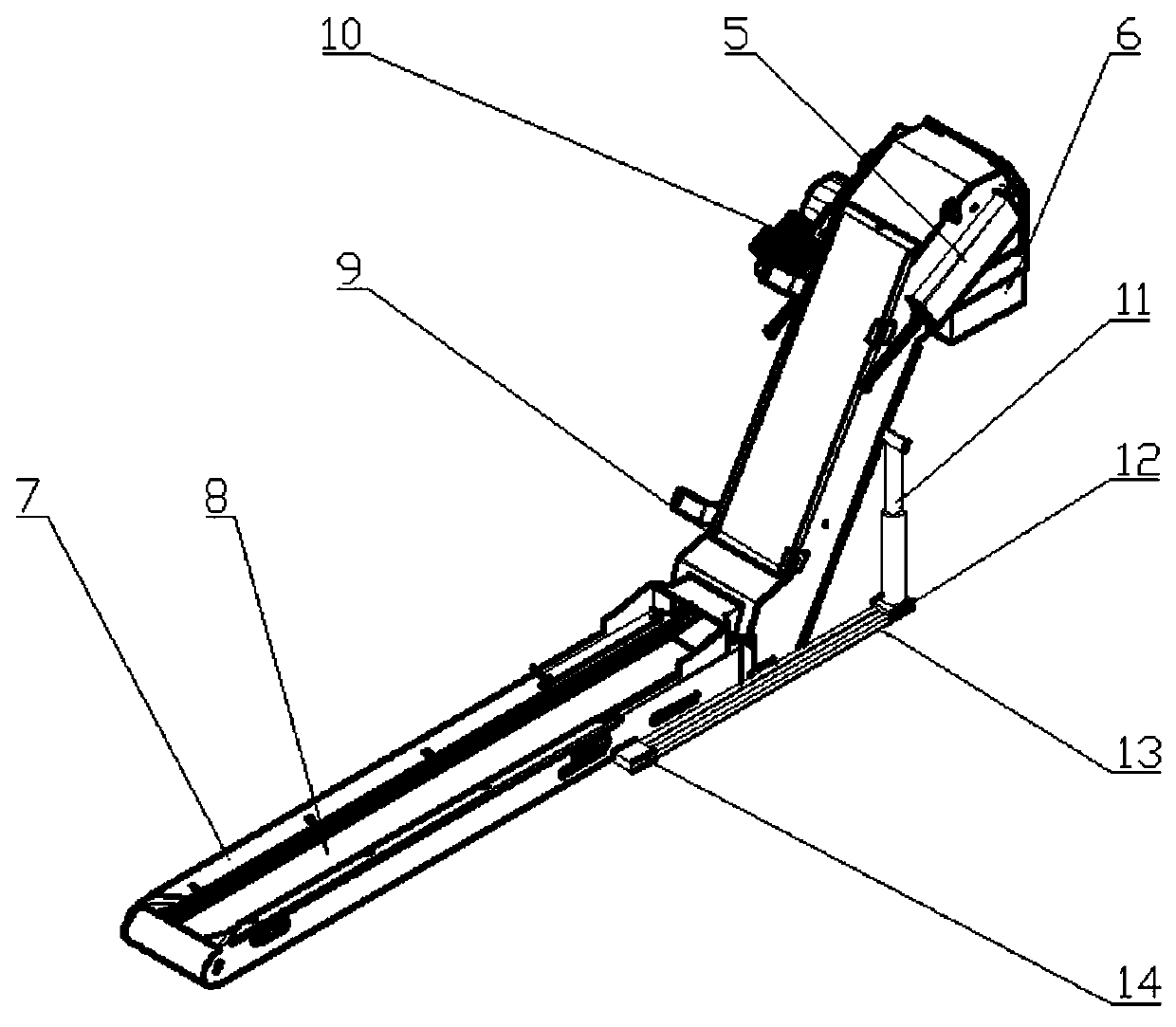

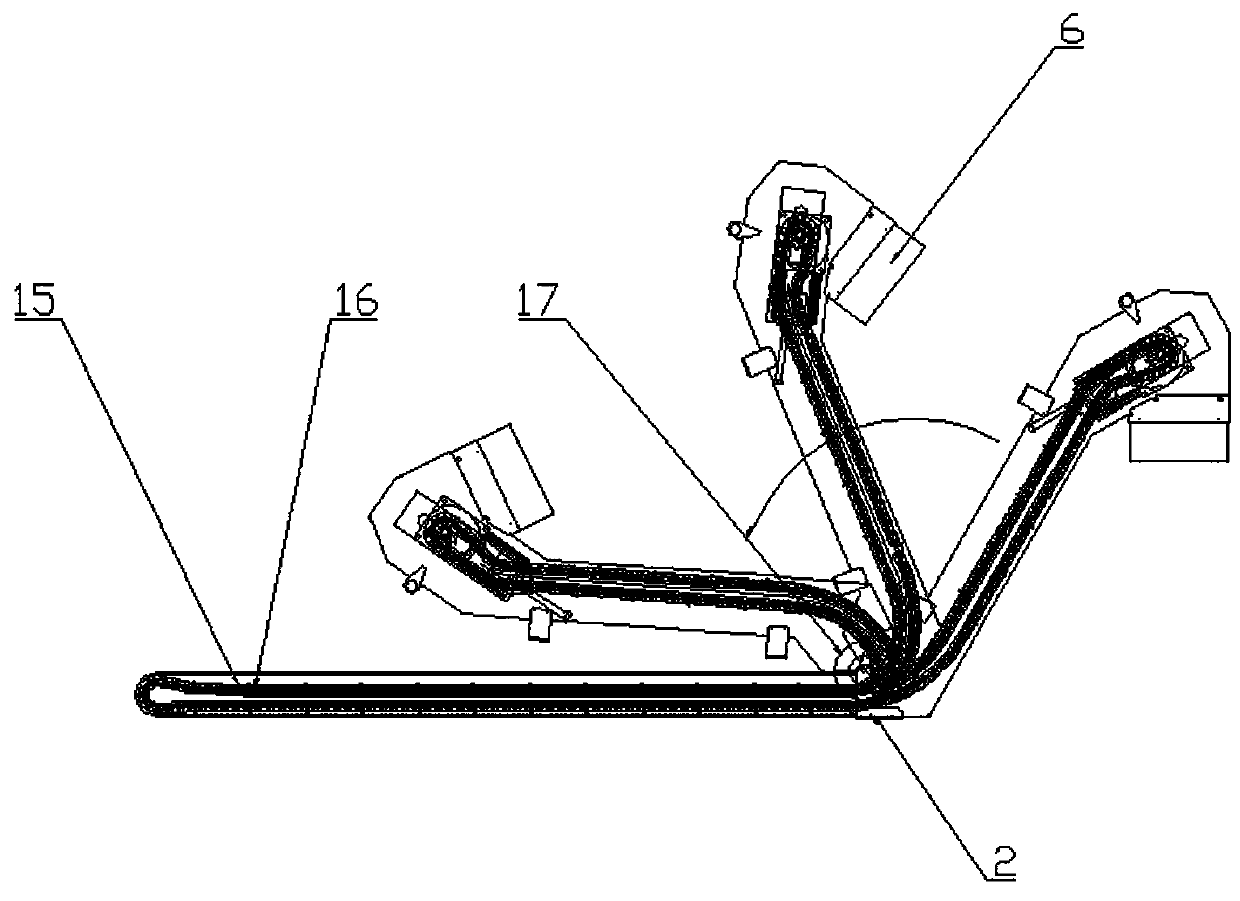

[0029] Example: such as Figure 1-4 As shown, a foldable chip removal machine includes a feeding chip removal rack 4, one end of the feeding chip removal rack 4 is provided with a feeding chip removal rack 1, and the other end of the feeding chip removal rack 4 is provided with a discharge bin 6, and the discharge bin 6 and both sides of the feeding chip rack 4 are equipped with a discharge angle adjustment seat 5 that is movably connected with the feeding chip rack 4, and the feeding chip rack 1 and the feeding chip rack 4 are provided with a feeder chip rack The folding rotating frame 2 connected by the 4-phase rotating pin shaft, the folding rotating frame 2 is provided with the rotating shaft 17 which is socketed with the folding rotating frame 2 phase pin shaft, and the rotating shaft 17 and the crawler ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com