Manual welding speed detection equipment

A speed detection, manual welding technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of inaccurate, time-consuming, and difficult to directly detect welding speed, and achieve simple structure, strong anti-interference, high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

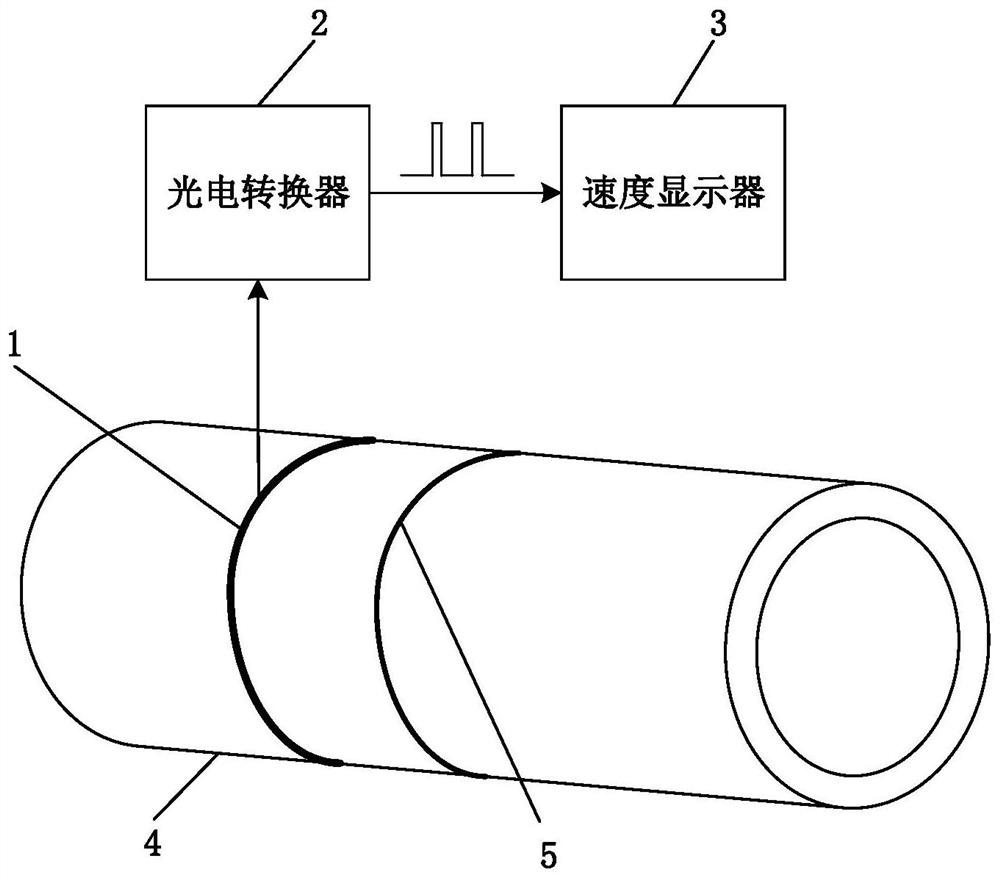

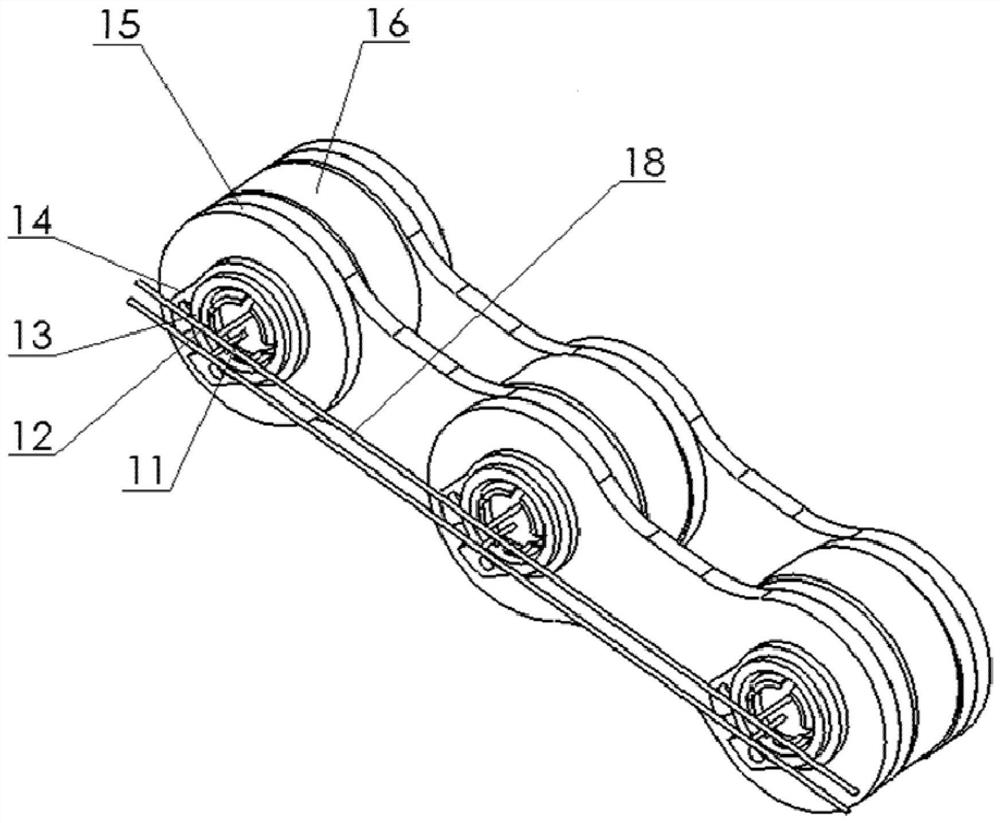

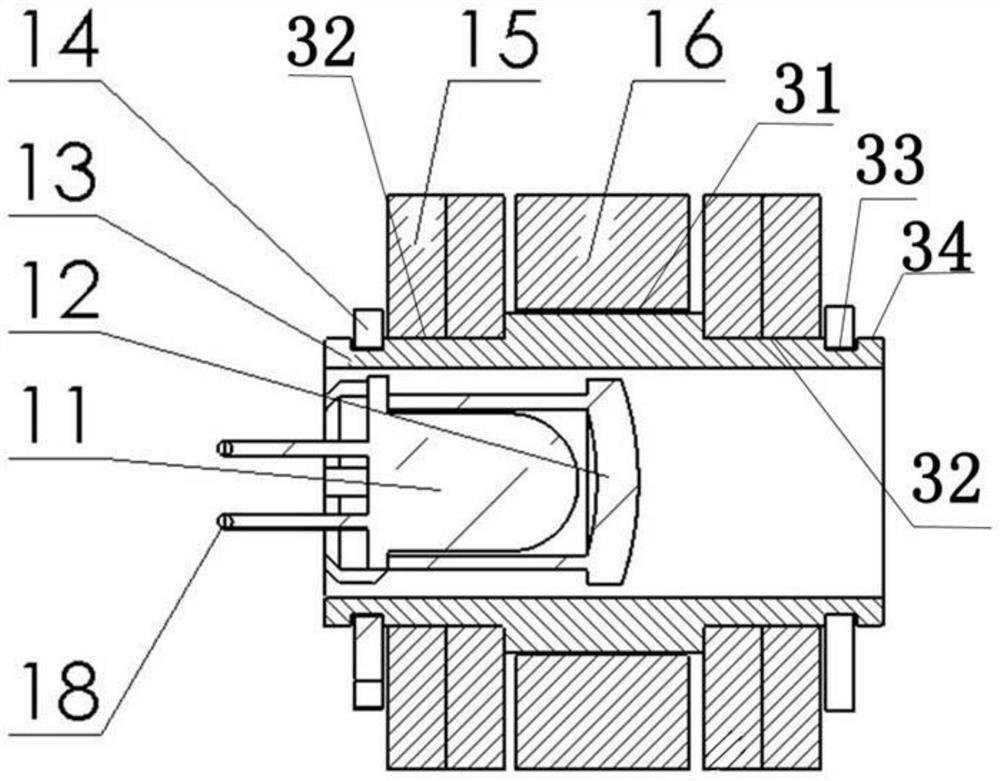

[0029] Such as figure 1 As shown, a manual welding speed detection device, the device includes an arc capture mechanism 1, a photoelectric converter 2 and a speed display 3;

[0030] The arc light capturing mechanism is fixed on the workpiece 4 to be welded parallel to the weld seam, and can be bent freely according to the shape of the weld seam 5. Its function is to capture the arc light incident by the arc perpendicular to the mechanism every time the arc moves a certain distance;

[0031] The photoelectric converter is used to convert the captured arc light signal into a pulse signal reflecting the welding speed;

[0032] The function of the speed display is to process the received pulse si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com