Automatic photovoltaic panel frame 45-degree sawing machine

A photovoltaic panel, automatic technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment, etc., can solve the problems of inability to guarantee the stability and accuracy of sawing, and the inability to fix the photovoltaic panel frame, so as to ensure safety. With the effect of stability, good self-locking, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the accompanying drawings, the components and their interrelationships of the present invention will be described.

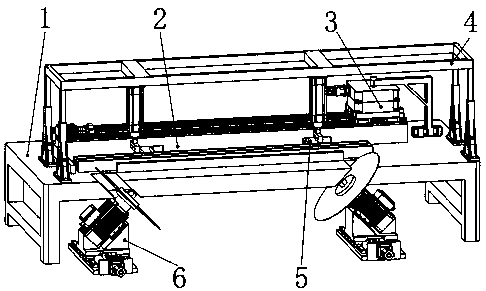

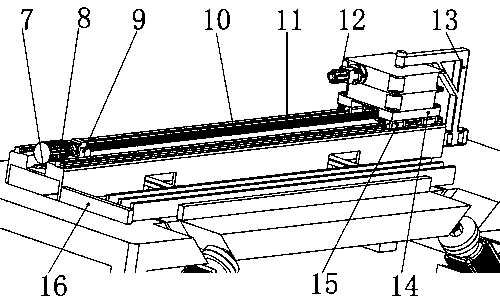

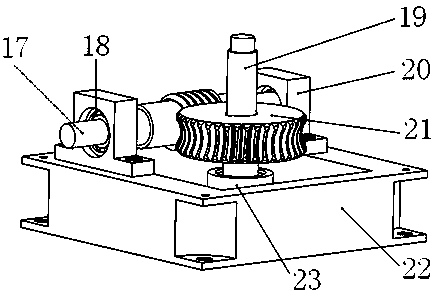

[0018] Overall structure of the present invention is as attached figure 1 As shown, the moving platform (2) is fixed on the workbench (1), the rotating mechanism (3) is connected with the sliding platform one (14) on the movement platform (2), and the fixed frame (4) is connected with the workbench (1) , the pushing alignment mechanism (5) is installed in the workbench (1), and the sawing mechanism (6) is fixed at the bottom of the workbench (1). as attached figure 2 , 3 , 4, 5, and 6, the connecting bearings at both ends of the long ball screw (10) are fixed on the screw fixing seat (9) and the screw support seat, and the slide table (14) is fixed on the four sliders (15 ), the motor (8) is fixed on the motion platform (2) through the motor bracket (7), and connected with the long ball screw (10) through the coupling, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com