Toughened-glass crushing and recycling device

A recycling device, the technology of tempered glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

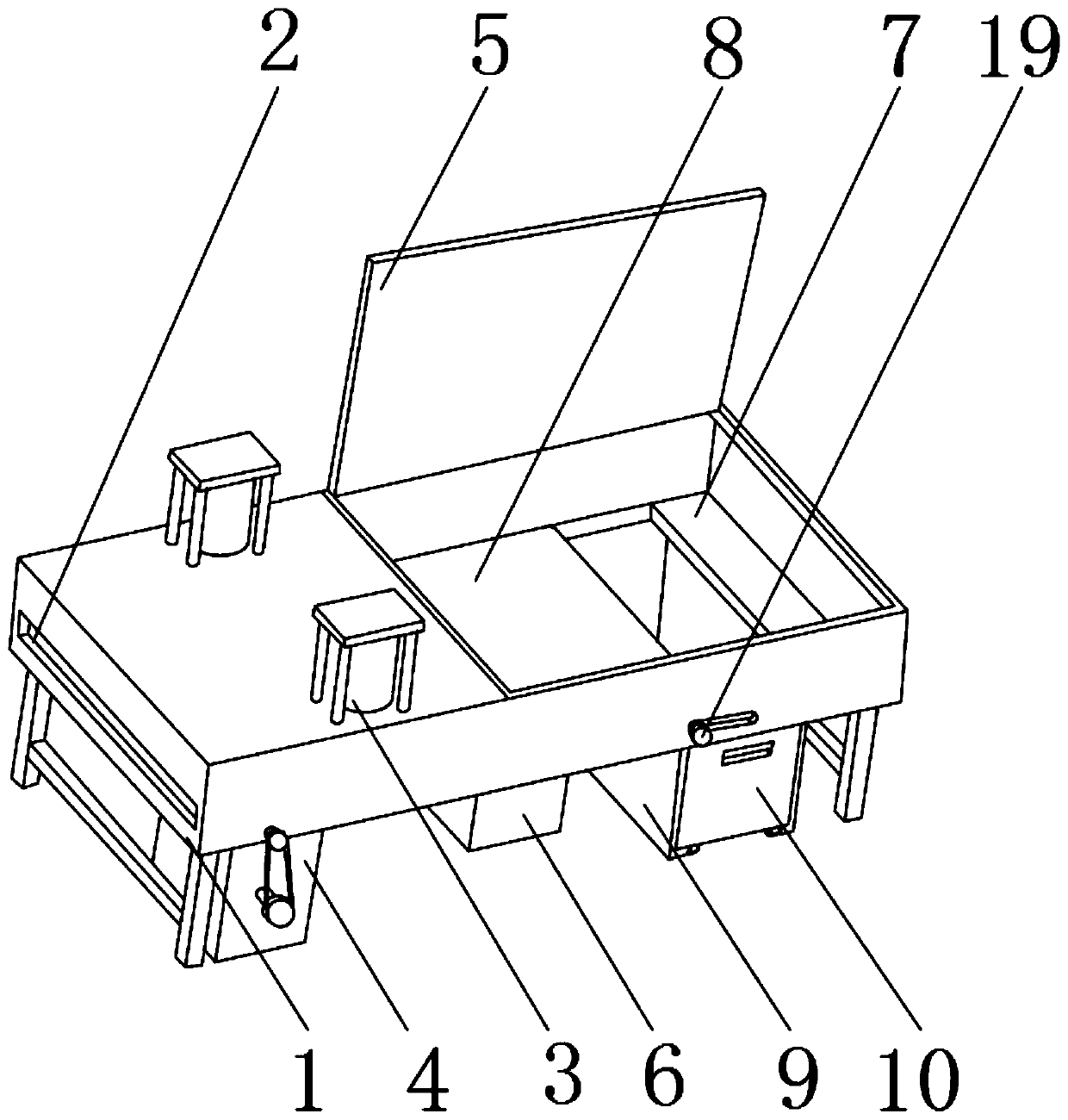

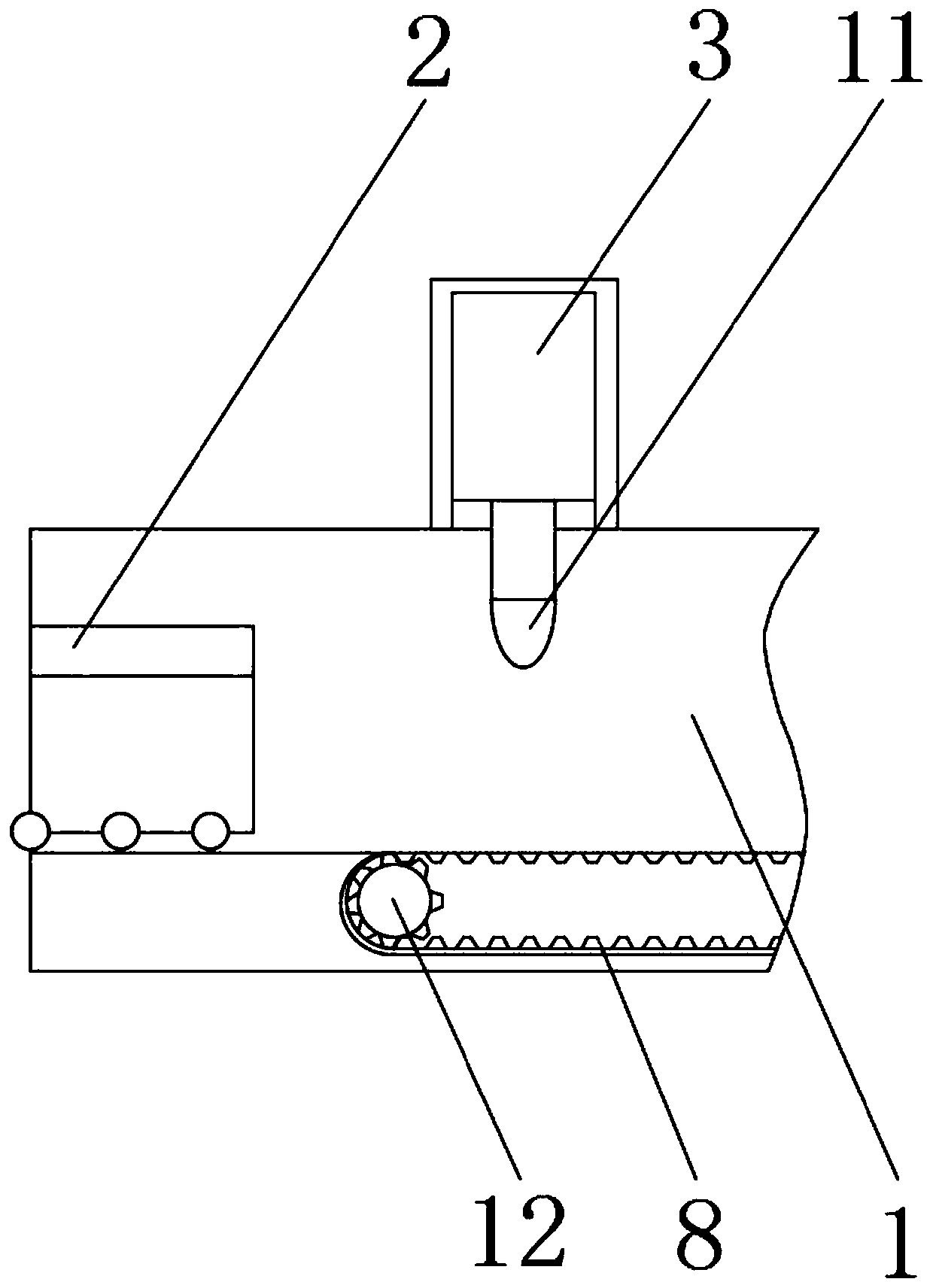

[0031] refer to Figure 1-2 , a broken tempered glass recovery device, comprising a recovery device shell 1, the internal front end of the recovery device shell 1 is fixed with a feed frame 2 by bolts, and the outer surface of the top end of the recovery device shell 1 is fixed by bolts on both sides of the front end A hydraulic rod 3 is installed, and the outer surface of the bottom end of the hydraulic rod 3 is welded with a striking head 11, the outer surface of the bottom end of the recovery device shell 1 is welded with a motor box 4 near the front end, and the top outer surface of the recovery device shell 1 is close to the rear end The position is installed with a movable plate 5 through the hinge movement, and the outer surface of the bottom end of the recovery device shell 1 is welded with a reserved box 6 near the center. A guide frame 9 is welded near the rear end, and a guide chute 13 is welded on the inner surface of the inner wall 7 .

[0032] refer to figure 1...

Embodiment 2

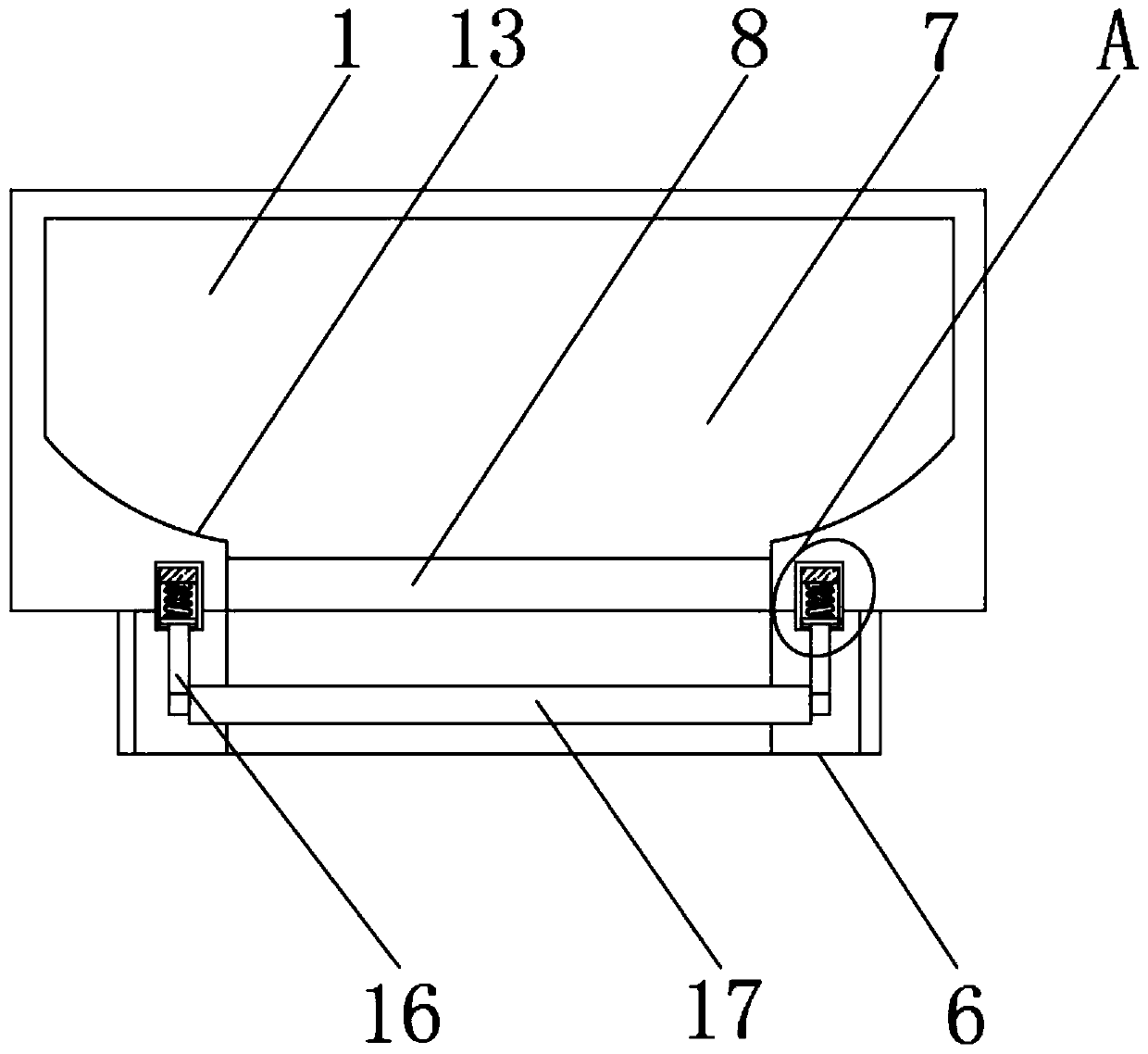

[0039] refer to Figure 2-6A fixed frame 14 is welded between the recovery device shell 1 and the reserved box 6 near both sides, and the inner surface of the fixed frame 14 is fixed with a pressure sensor 15 by bolts near the outer surface of the top end, and the outer surface of the bottom end of the pressure sensor 15 is A connecting rod 16 is movably installed by a spring, a conveyor belt 8 is movably installed on the inner surface of the inner wall 7 near the center, and a drive roller 12 is fixedly installed inside the conveyor belt 8 near the front end, and a pressure roller is welded on the outer surface of the bottom end of the connecting rod 16 17, and the top of the pressure roller 17 is fixedly installed near both sides of the pinch roller 18, and the inside of the conveyor belt 8 is movably installed with a movable roller 19 near the rear end.

[0040] refer to Figure 4 , The inner surface of the fixed frame 14 is provided with a guide groove, which facilitates ...

Embodiment 3

[0044] refer to figure 1 , Figure 6 and Figure 7 The inside of the guide frame 9 is movably equipped with a collection box 10, and the front end of the collection box 10 is movably equipped with a dodge door 20 through a hinge, and two electric telescopic rods 21 are fixedly installed in the inside of the collection box 10.

[0045] refer to Figure 7 , the inside of the collection box 10 is provided with a retractable groove, and two storage boxes are installed for the movement of the retractable groove. The handle is capable of pulling the collection box 10 outward.

[0046] refer to Figure 7 , the outer surface of the bottom of the collection box 10 near the four corners is fixed with pillars by bolts, the outer surface of the bottom of the pillars is movably equipped with rollers through the rotating shaft, rollers are installed at the bottom of the collection box 10, and the collection box is convenient 10 slides.

[0047] There are two storage boxes installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com