Nickel phosphate/Co-MOFs composite material, and preparation methods and application thereof

A composite material, nickel phosphate technology, applied in the direction of material electrochemical variables, etc., can solve the problems of agglomeration and low specific surface area, and achieve the effects of simple preparation process, increased specific surface area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

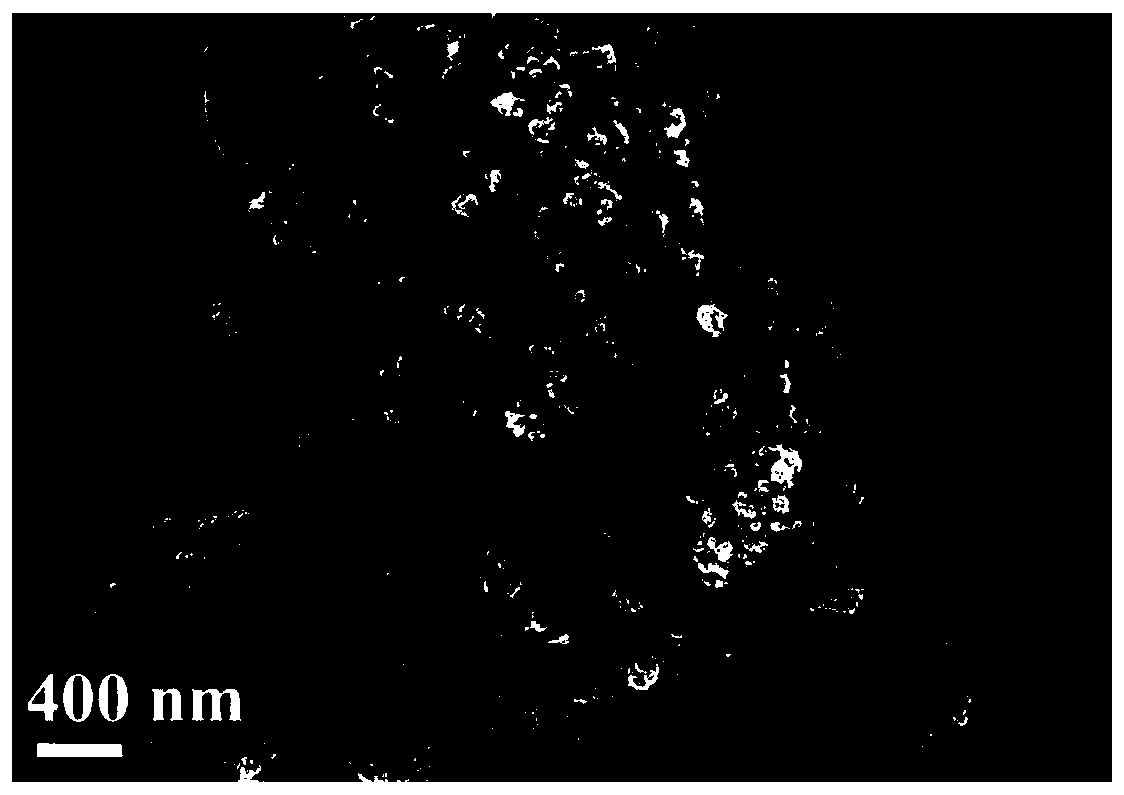

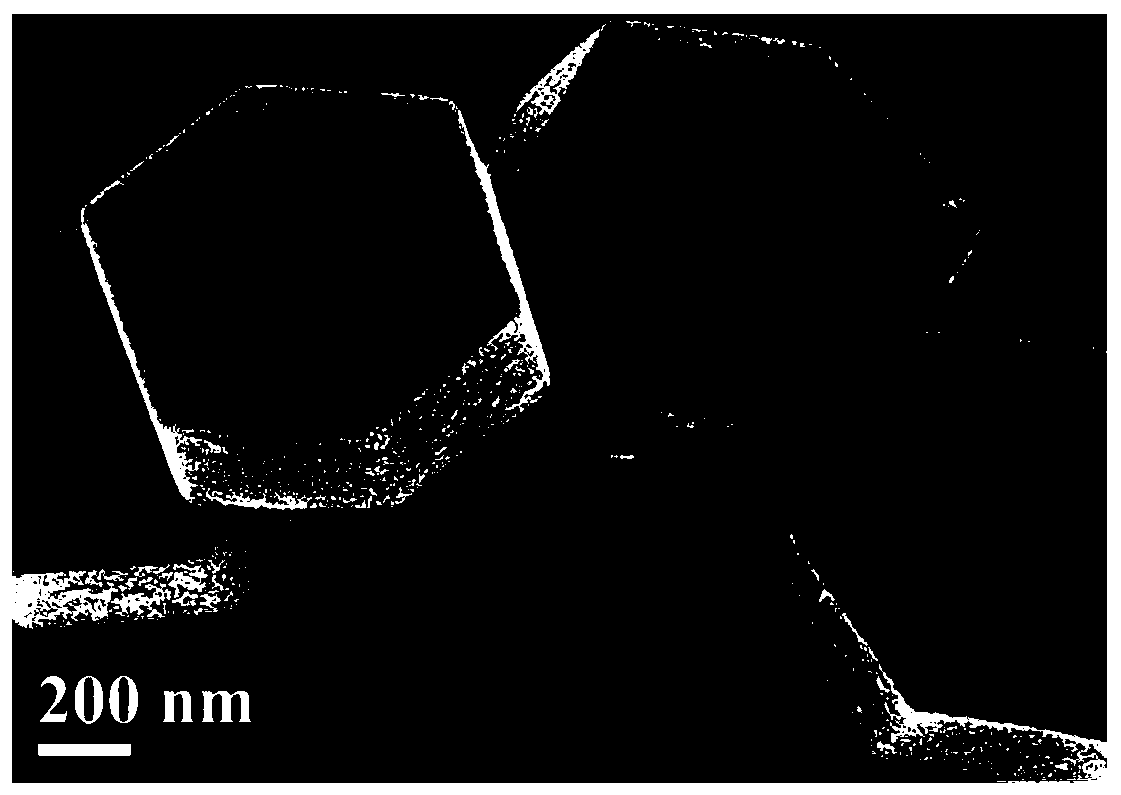

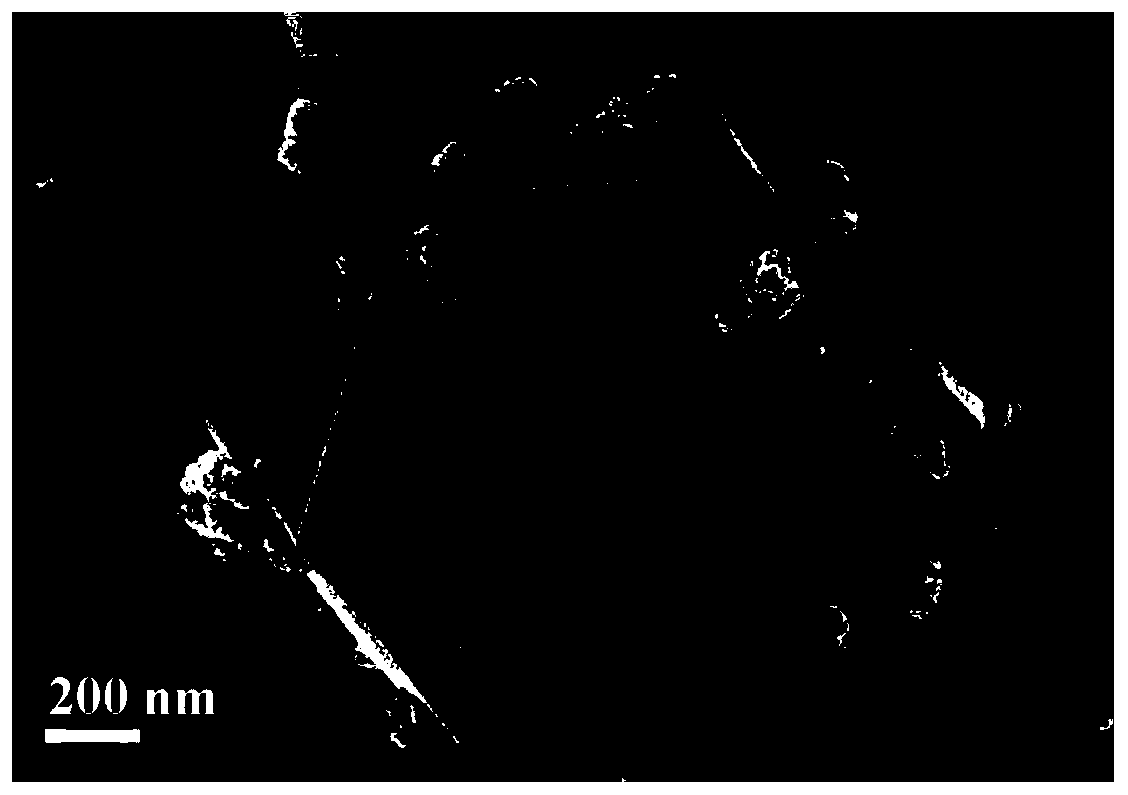

Image

Examples

Embodiment 1

[0034] Preparation of nickel phosphate / Co-MOFs composites

[0035] (1) After dissolving nickel nitrate and ammonium dihydrogen phosphate in deionized water, add N,N-dimethylformamide, mix well, and conduct a hydrothermal reaction at 100°C in the reactor for 5 hours. After the hydrothermal reaction is completed, filter and take Precipitate, wash the precipitate and dry at 60°C for 10 hours to obtain nano-nickel phosphate, wherein the molar ratio of nickel element in nickel nitrate, phosphorus element in ammonium dihydrogen phosphate, water and N,N-dimethylformamide is 40 :20:6:9;

[0036] (2) Disperse the nano-nickel phosphate prepared in step (1) in methanol, then add cobalt nitrate, add 2-methylimidazole methanol solution after stirring for 2 hours, obtain the reaction solution, stir the reaction solution for 2 hours and then let it stand 24h, centrifuge and get precipitation, make nickel phosphate / Co-MOFs composite material, wherein the mass ratio of nano-nickel phosphate, ...

Embodiment 2

[0038] Preparation of nickel phosphate / Co-MOFs composites

[0039] (1) Dissolve nickel sulfate and sodium dihydrogen phosphate in deionized water, add N,N-dimethylformamide, mix well, and conduct a hydrothermal reaction at 150°C for 10 hours in the reactor, and filter to take Precipitate, wash the precipitate and dry it at 60°C for 10 hours to obtain nano-nickel phosphate, wherein the molar ratio of nickel element in nickel salt, phosphorus element in phosphate, water and N,N-dimethylformamide is 40:20 :35:1;

[0040] (2) Disperse the nano-nickel phosphate prepared in step (1) in ethanol, then add cobalt sulfate, add 2-methylimidazole ethanol solution after stirring for 1h, obtain the reaction solution, stir the reaction solution for 0.5h and then statically Put 10h, centrifuge and get precipitation, make nickel phosphate / Co-MOFs composite material, wherein the mass ratio of nano-nickel phosphate, cobalt salt and 2-methylimidazole prepared in step (1) in the reaction solution...

Embodiment 3

[0042] Preparation of nickel phosphate / Co-MOFs composites

[0043] (1) After dissolving nickel chloride and diammonium hydrogen phosphate in deionized water, add N,N-dimethylformamide, mix well, and conduct a hydrothermal reaction at 180°C for 3 hours in the reactor, and filter after the hydrothermal reaction is completed Take the precipitate, wash the precipitate and dry it at 60°C for 10 hours to obtain nano-nickel phosphate, wherein the molar ratio of nickel in the nickel salt, phosphorus in the phosphate, water and N,N-dimethylformamide is 40: 20:18:5;

[0044] (2) Disperse the nano-nickel phosphate prepared in step (1) in N,N-dimethylformamide, then add cobalt chloride, stir for 5h and then add 2-methylimidazole N,N-dimethylformamide base formamide solution, to obtain the reaction solution, the reaction solution was stirred for 5h and left to stand for 18h, centrifuged to get the precipitate, and the nickel phosphate / Co-MOFs composite material was obtained, wherein the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com