Special tool for quality inspection of weld joints in pipelines

An internal weld and quality inspection technology, applied in the direction of optical testing for defects/defects, can solve the problems of long pipelines, inability to accurately find the position of the weld, and inability to judge the quality of the weld to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

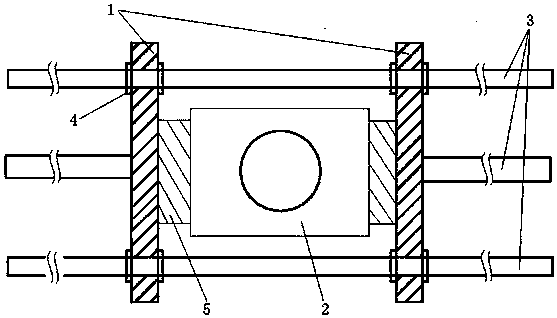

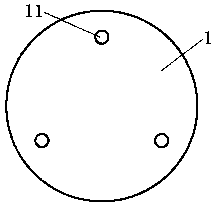

[0013] Example figure 1 As shown, the special tooling of the present invention for the inspection of the internal weld seam of the pipeline includes two discs 1, an endoscope 2 and a long screw 3, and the two discs 1 are arranged in parallel at intervals and have a diameter smaller than that of the inner ring of the pipeline. The two discs 1 have through holes 11 equidistantly spaced from each other, and the long screw 3 penetrates through the through holes 11 on the two discs 1 and uses nuts 4 to fix the positions of the two discs 1. The endoscope 2 is clamped between the two discs 1 and the lens direction is consistent with the radial direction of the discs 1 .

[0014] Preferably, there are at least three through holes 11 on the surface of the two disks 1 , and there are at least three long screws 3 .

[0015] Preferably, the two discs 1 are wooden discs with a distance of 200 mm. The wooden disc prevents the tooling from scratching the inner wall of the pipeline when it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com