Bushing connection structure of air conditioner compressor support

A technology of air-conditioning compressors and connecting structures, which is applied in mechanical equipment, air handling equipment, machines/engines, etc., can solve the problems of increased manufacturing costs, high rework costs, scrapping, etc., to improve assembly accuracy and assembly efficiency, and reduce labor Strength and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

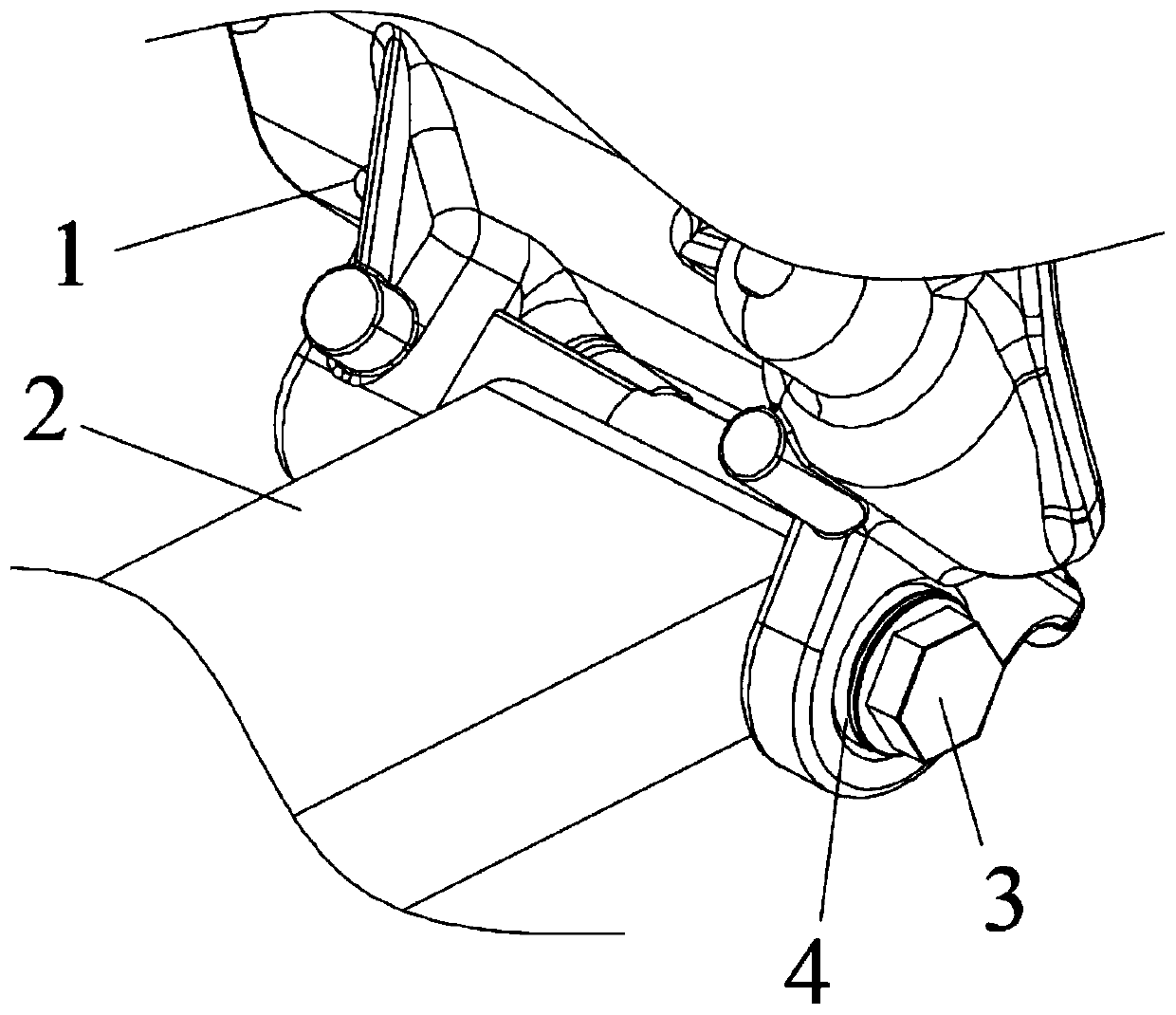

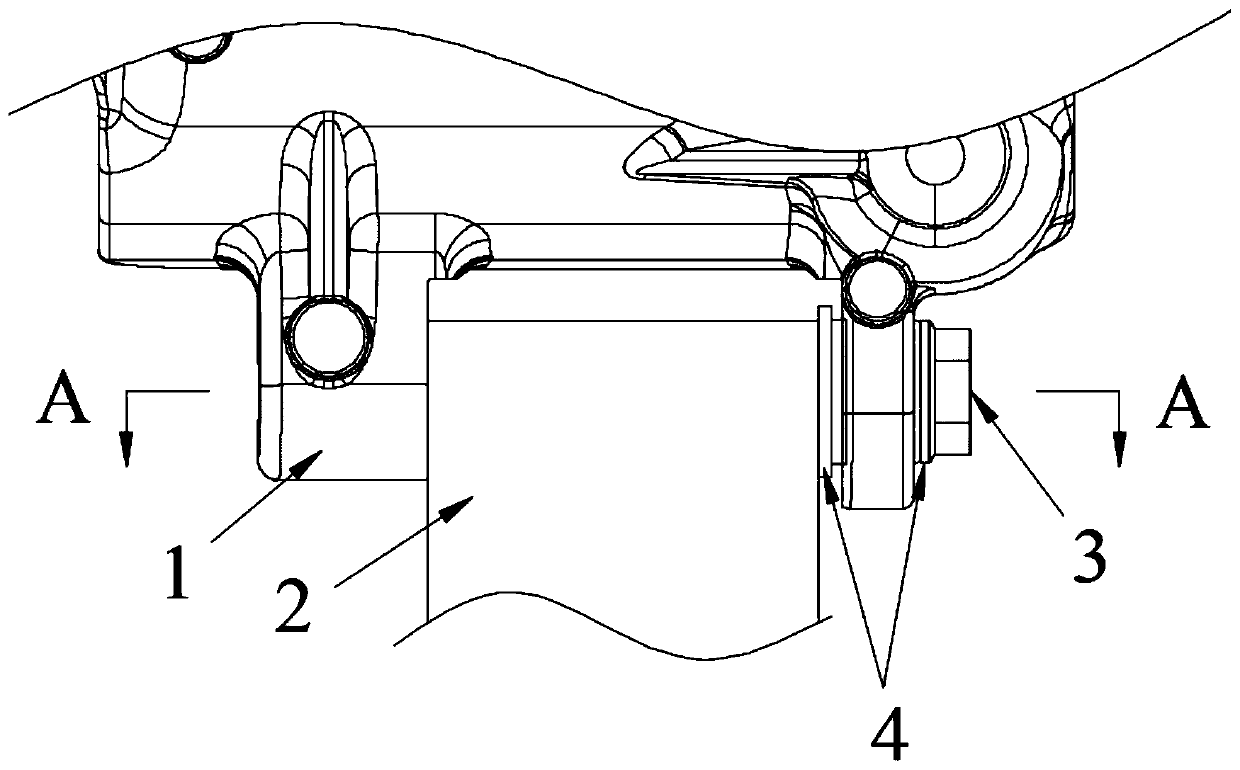

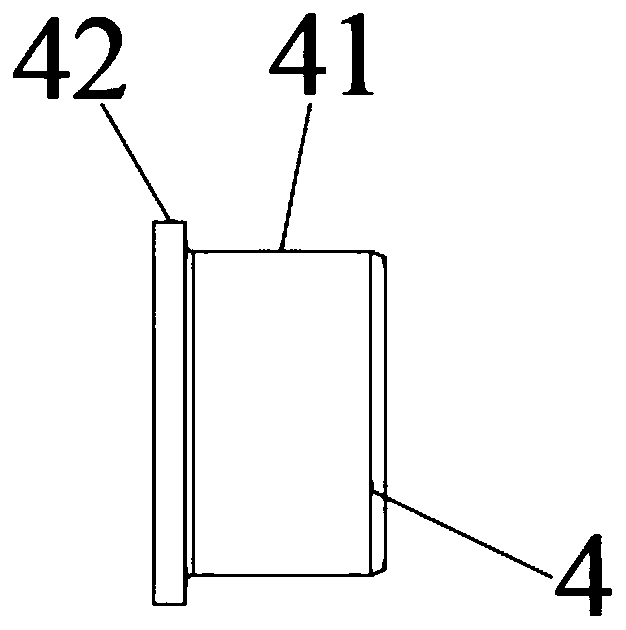

[0016] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a bush connection structure of an air conditioner compressor bracket, which includes an air conditioner compressor bracket 1, assembly parts 2, assembly bolts 3 and bushings 4; the air conditioner compressor bracket 1 includes a first Assembly through holes and second assembly threaded holes; the assembly part 2 is installed between the first assembly through hole and the second assembly threaded hole; the bushing 4 includes a large-diameter circular plate 42 and a small-diameter cylinder 41 integrally formed T-shaped structure, and an axial through hole is opened at the center; the small-diameter cylinder 41 of the bush 4 is inserted into the first assembly through hole, and the end face of the large-diameter disc 42 of the bush is pressed against the fitting On one end of the assembly; the other end of the assembly is pressed on the second assembly threaded hole; after the assembly bolt 3 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com