Horizontal-type-structure repairing equipment for stainless-steel-wrapped vertical column remanufacturing

A stainless steel and remanufacturing technology, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of cumbersome assembly process, small applicable range of column size, low assembly efficiency and accuracy, and improve assembly efficiency and assembly accuracy. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

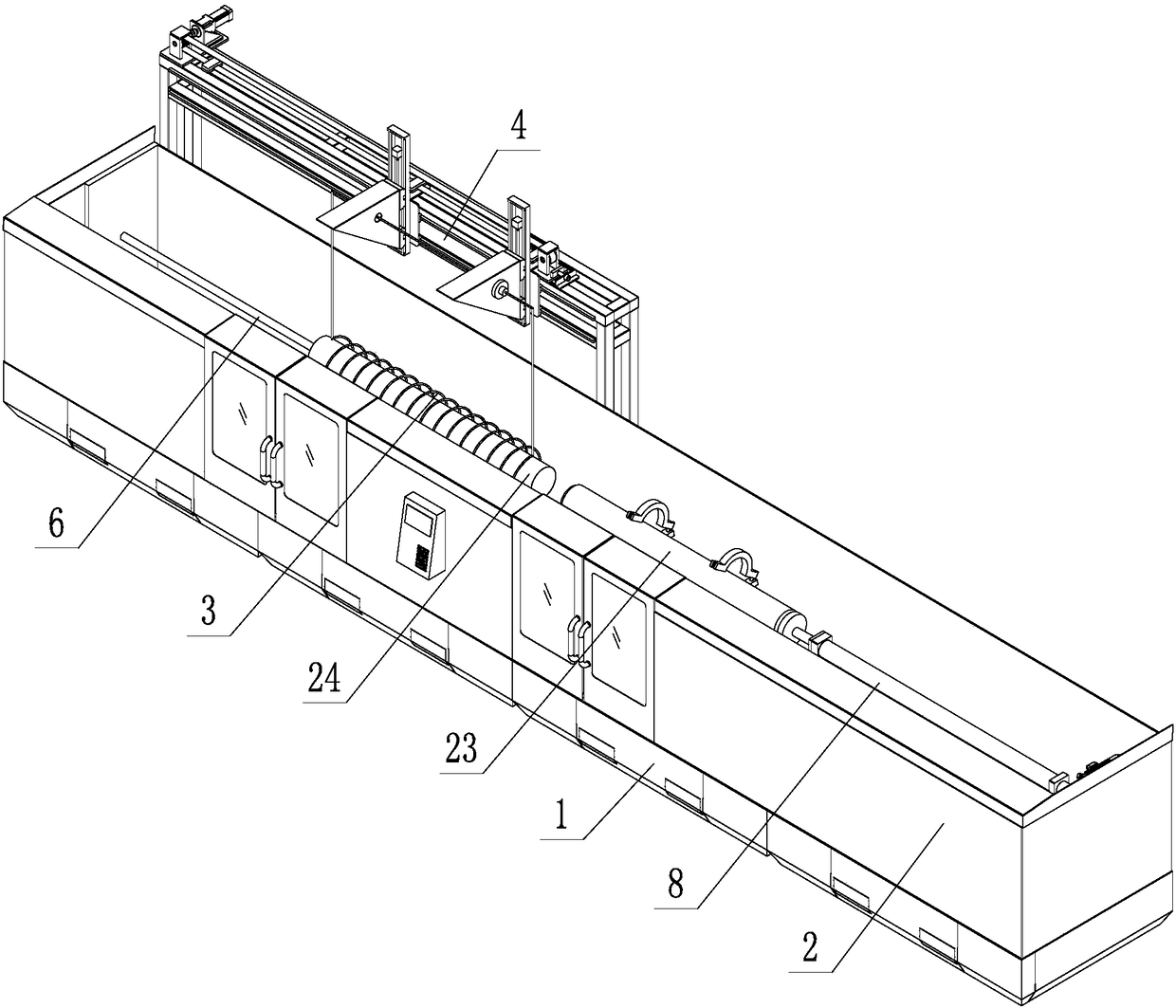

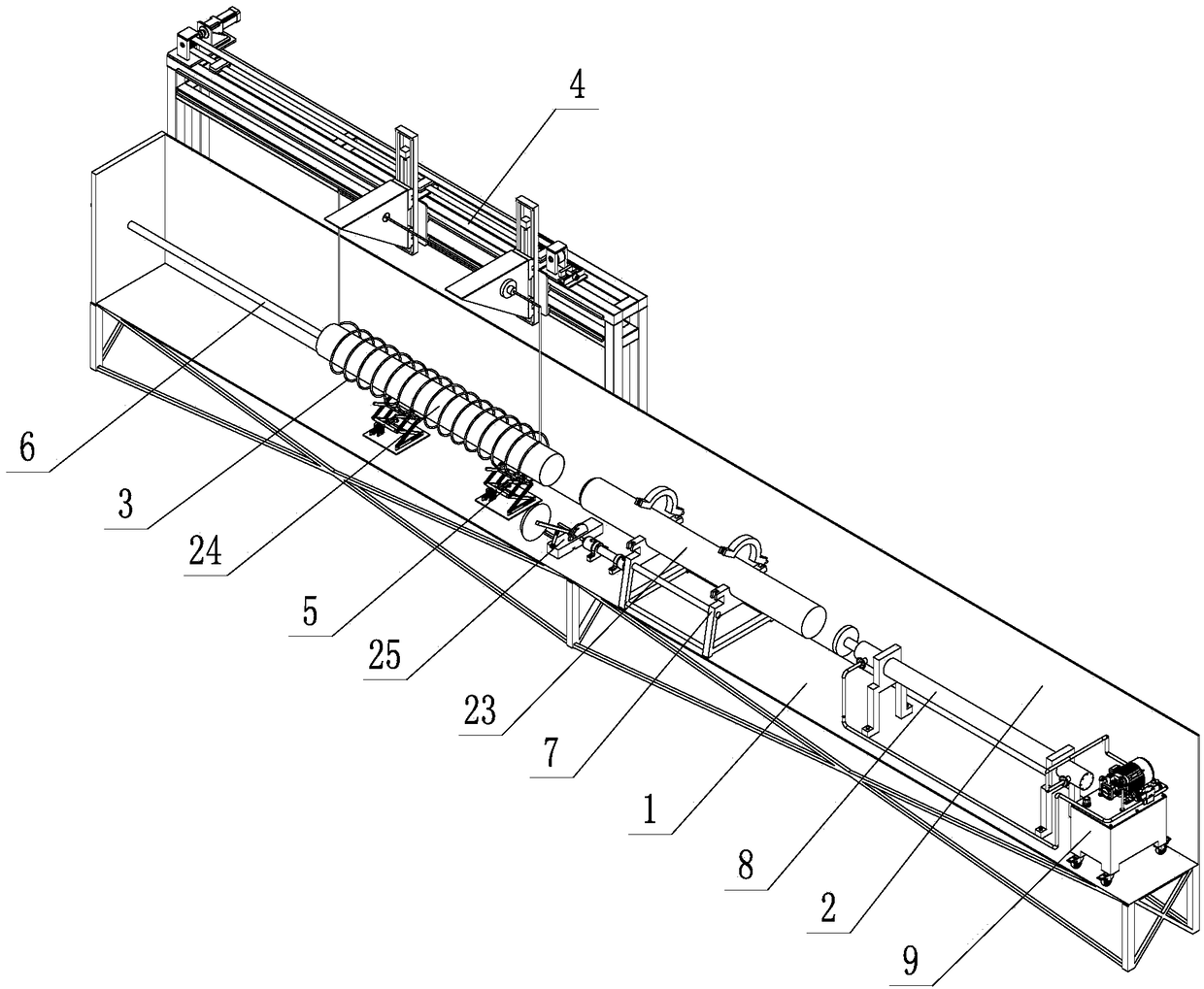

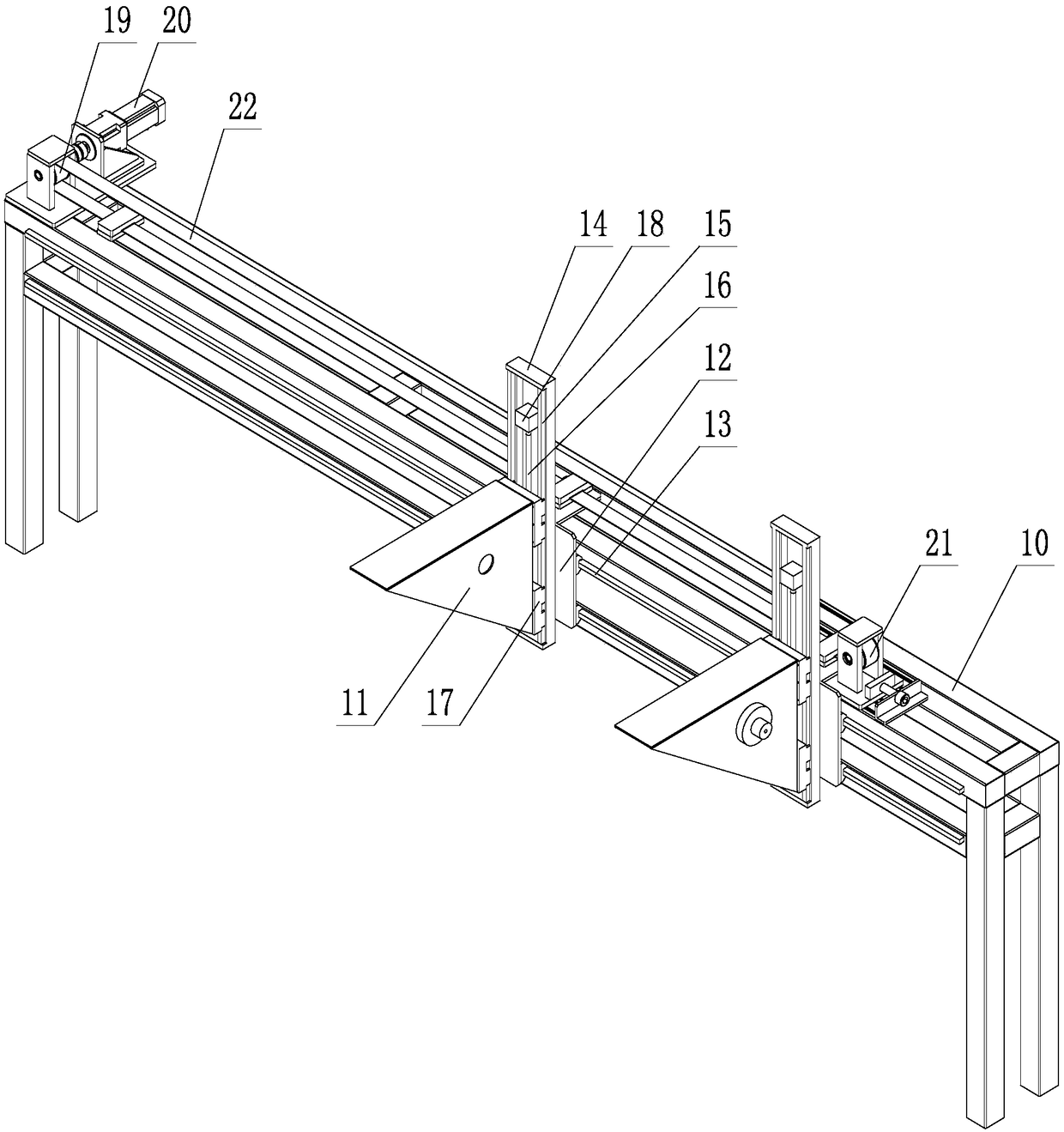

[0018] Such as Figure 1~4 As shown, a horizontal structure stainless steel clad column remanufacturing repair equipment, including base 1, enclosure 2, intermediate frequency heating tube 3, intermediate frequency heating tube position adjustment mechanism 4, stainless steel clad lifting support frame 5, stainless steel clad Layer axial limit ejector rod 6, column support frame 7, column push hydraulic cylinder 8 and hydraulic station 9; the enclosure 2 is fixed on the base 1, and the intermediate frequency heating tube 3 is hoisted on the intermediate frequency heating tube position adjustment mechanism 4, and the intermediate frequency heating tube 3 is located in the enclosure 2; the stainless steel cladding layer axial limit ejector rod 6, the stainless steel cladding layer lifting support frame 5, the column support frame 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com