Remote control cement head

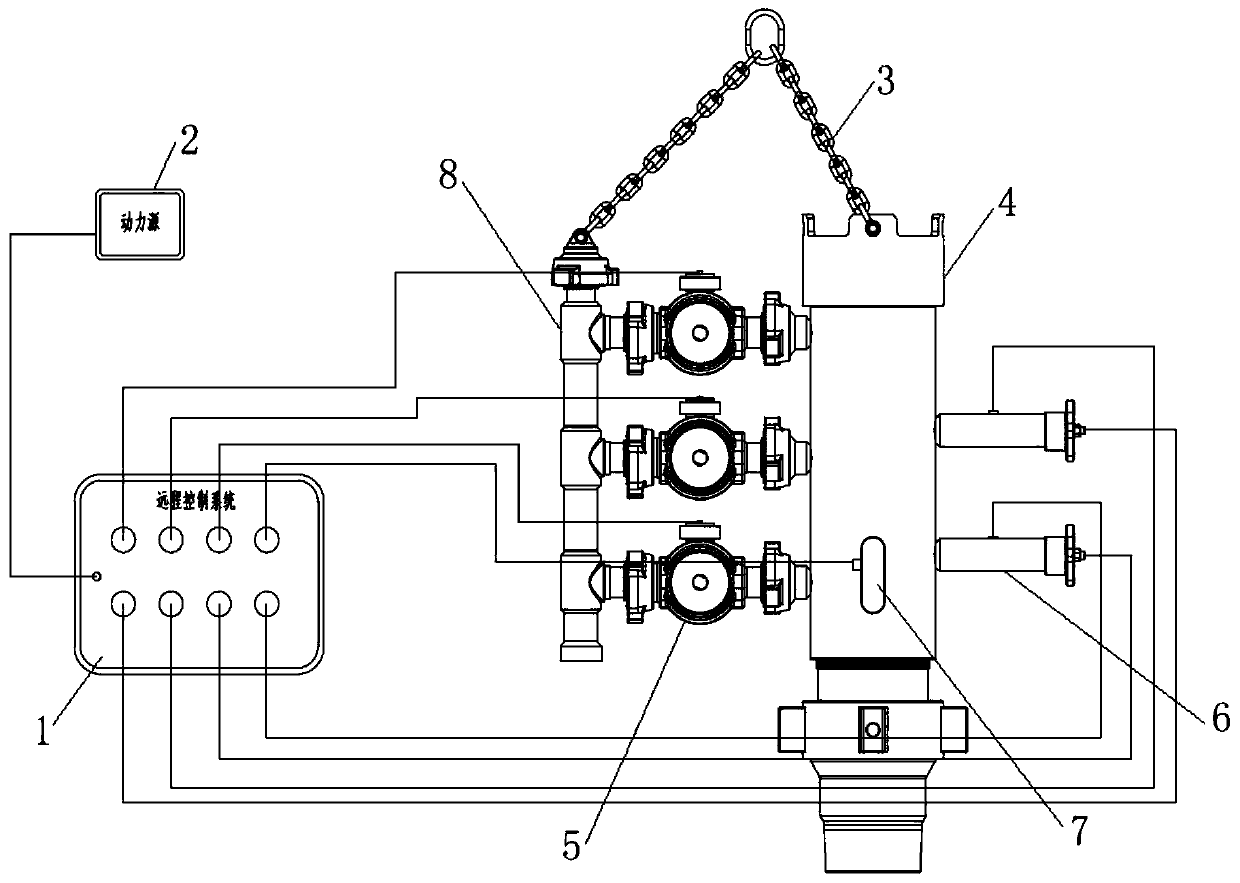

A remote control and remote control system technology, which is applied in the field of oil and gas exploration equipment, can solve problems such as increased operational difficulty, great danger to construction personnel, and complex cementing operation environment, so as to ensure safety and reduce operation risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

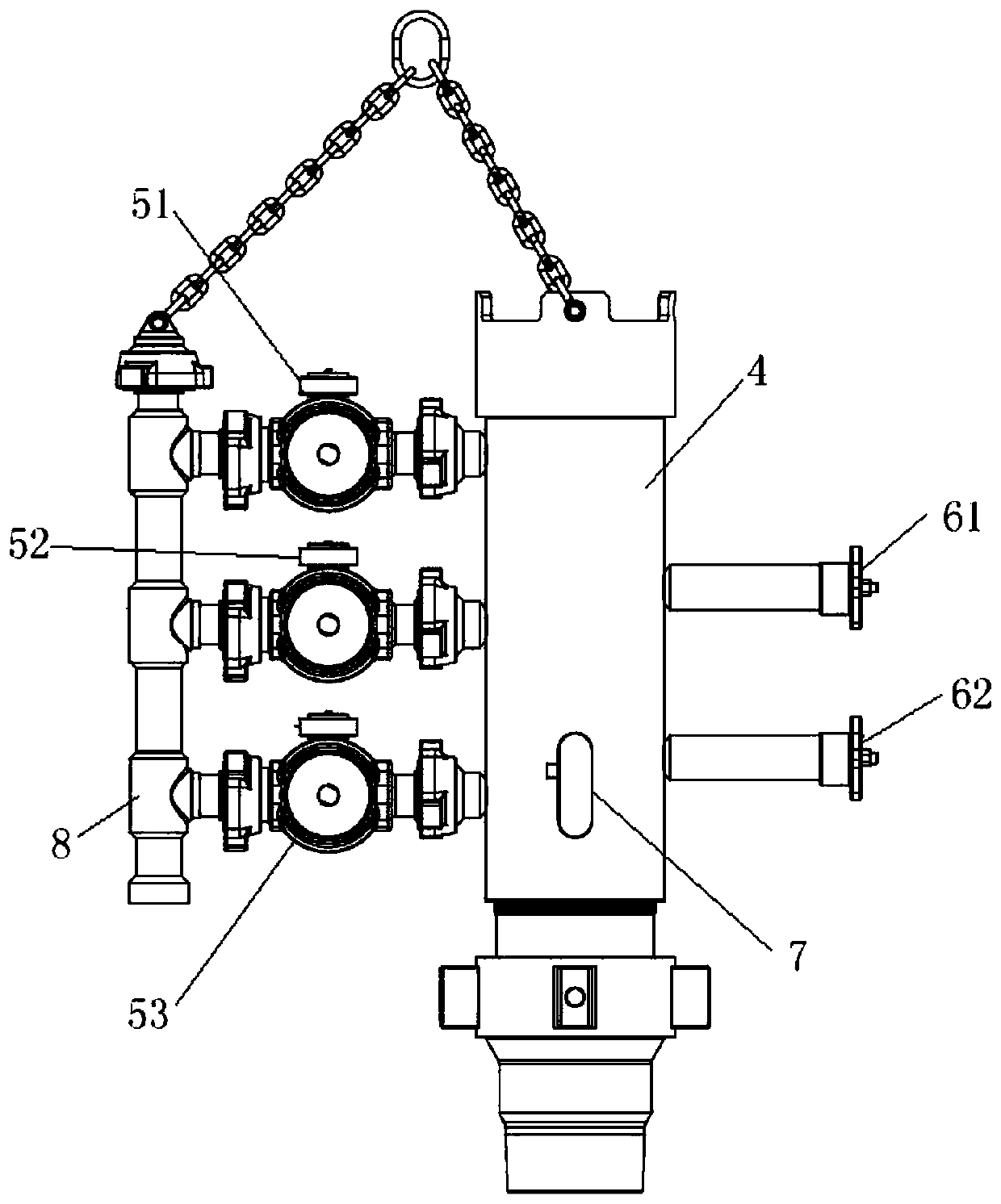

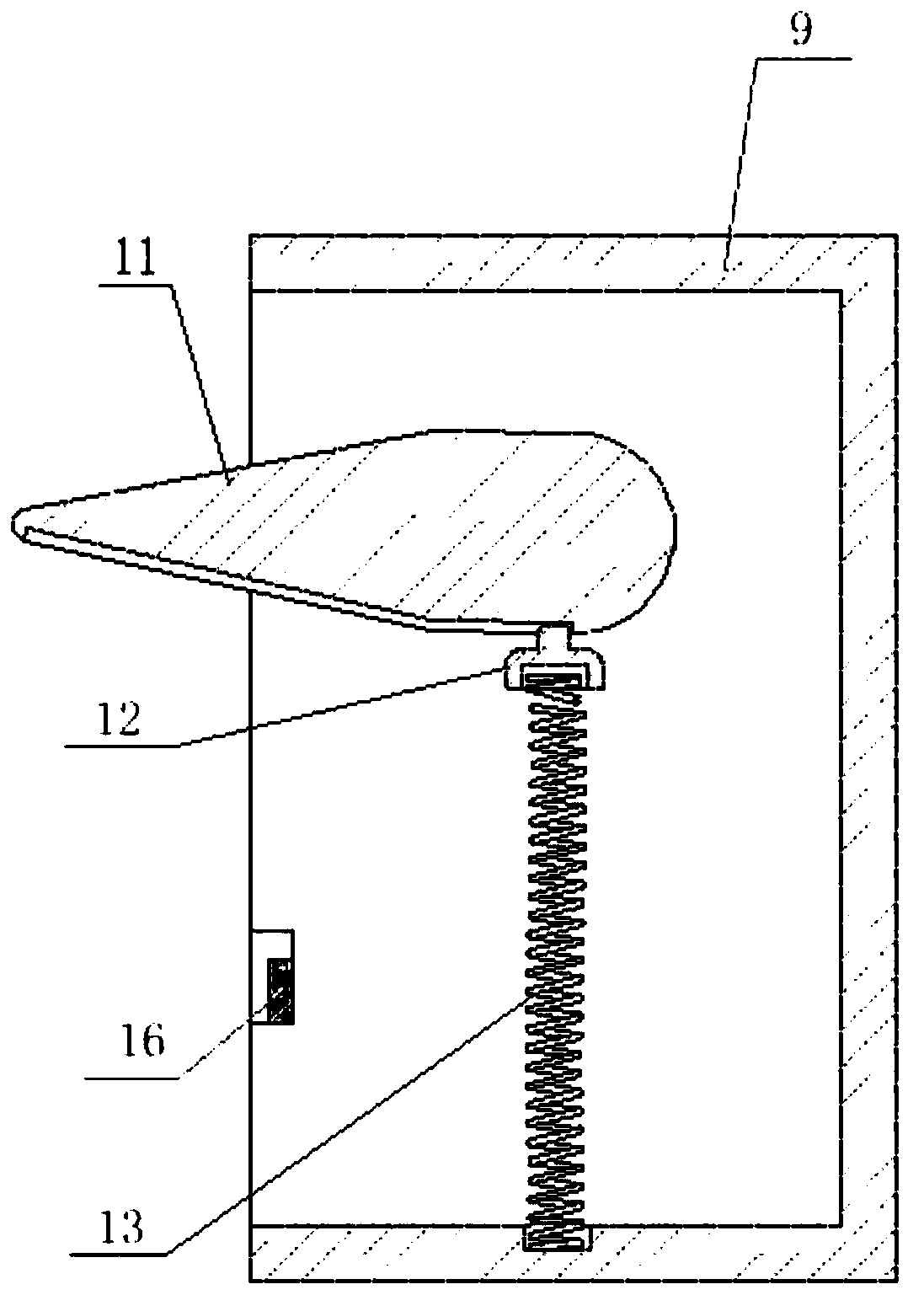

Embodiment 1

[0025] Embodiment 1. In this embodiment, three hydraulic plug valves 5 and two hydraulic retaining pins 6 are used as an example. Before the cementing operation, the hydraulic control cement head 3 is connected to the casing, and the remote control system 1 is passed through Each control pipeline is connected with the hydraulic cock valve 5 on the hydraulically controlled cement head 3 , the hydraulic stop pin 6 , and the indicator mechanism 7 . Connect the power source 2, close the corresponding hydraulic plug valve 5, hydraulic stop pin 6, and indicator mechanism 7 through the remote control system 1, place the double rubber plug, and close the cement head cap; through the remote control system 1 to control the opening of the third hydraulic cock valve 53 connected to the side port of the lower end of the circulation manifold 8 to inject cement slurry, at this time the indicator mechanism 7 is in the closed state; when the bottom plug needs to be released, the remote control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com