Compound corrosion inhibitor suitable for N80 steel and stainless steel galvanic couples in oilfield sewage medium and preparation method thereof

A technology of oilfield sewage and corrosion inhibitor, which is applied in the field of corrosion and protection of metal materials, can solve the problems of low corrosion inhibition efficiency of linseed oil corrosion inhibitor and unfavorable industrial application, etc., to inhibit uniform corrosion and pitting corrosion, and improve dissolution Sexuality and dispersion, the effect of reducing the potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present invention proposes a compound corrosion inhibitor suitable for N80 steel and stainless steel galvanic couple in oilfield sewage medium and a preparation method thereof, which specifically includes the following steps:

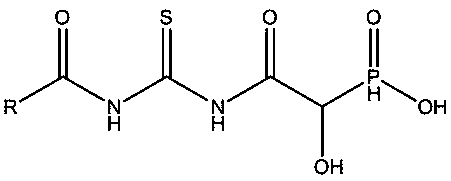

[0053] Step 1: Preparation of ureido linseed oil.

[0054]Add linseed oil and xylene solvent into a 250 ml four-necked bottle, add 20-40 ml of xylene per mole of linseed oil, slowly heat to 110-160°C under nitrogen protection, and the molar ratio is 1:0.5 – 1:1.2 Slowly add thiourea to the above mixture, condense and reflux for 6 – 8 h under the condition of mechanical stirring, and obtain the urea-based linseed oil product.

[0055] Among them, the raw material of linseed oil was purchased from Zhangjiakou Xinte Vegetable Oil Co., Ltd., and its main components are shown in the following table:

[0056]

[0057] The reaction equation is:

[0058]

[0059] Wherein R includes R1, R2, R3 and R4;

[0060]

[0061]

[0062]

[00...

Embodiment 2

[0079] The main difference between this embodiment and embodiment 1 lies in step three, specifically:

[0080] Mix phosphonourea-based linseed oil derivatives, polyaspartic acid, sodium molybdate and isopropanol according to their mass fractions of 60%, 10%, 20% and 10%, respectively, to obtain a compound buffer etchant.

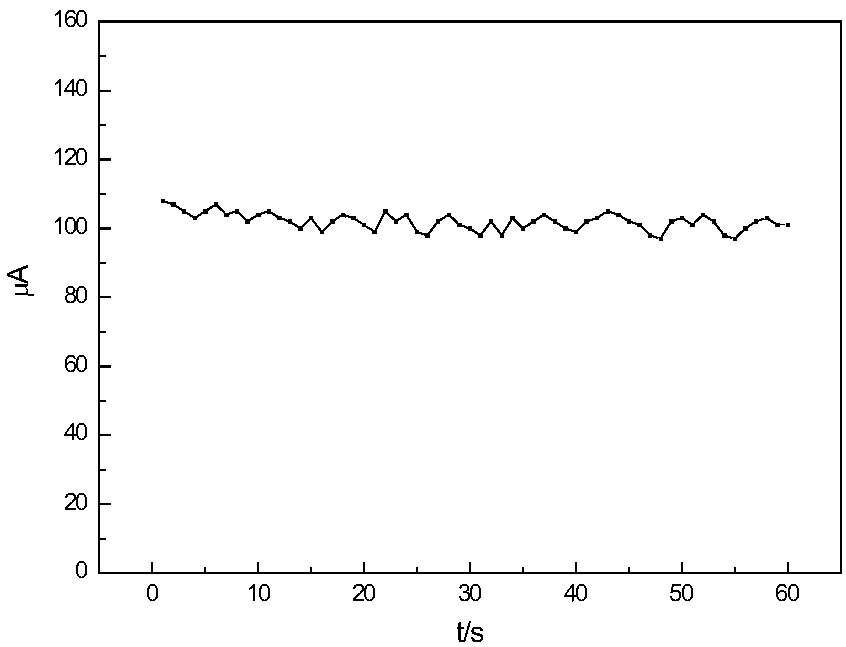

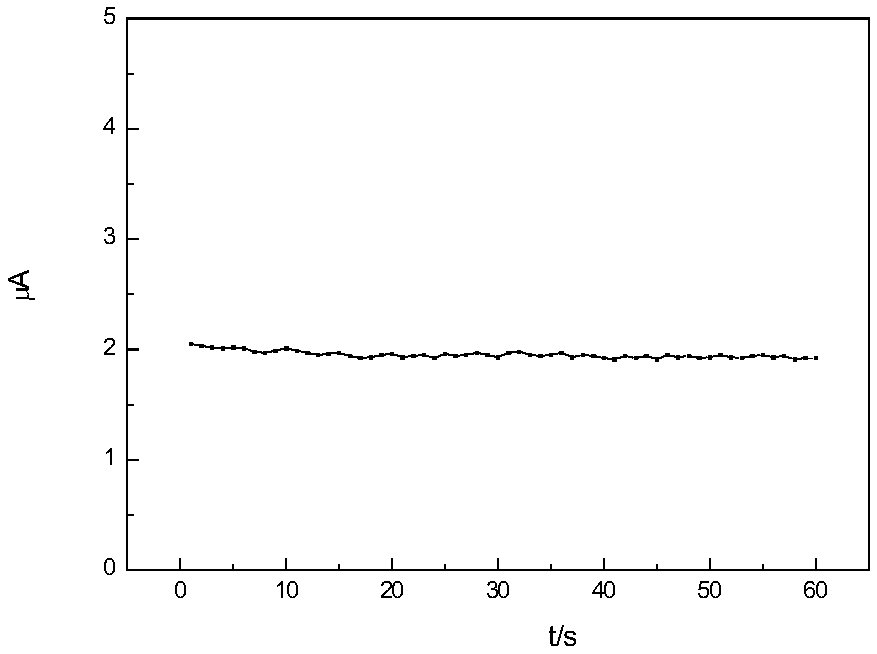

[0081] Add the obtained composite corrosion inhibitor to every 100g of simulated oilfield sewage medium (Tahe oilfield sewage testing results: distilled water + 13.6% NaCl + 4.5% CaCl2 + 0.8% MgCl2.6H20 + 0.6% Na2SO4 + 0.08% KCl) The specific gravity of 5 mg compound corrosion inhibitor was added to the simulated oilfield sewage corrosion solution, and the N80 steel and stainless steel galvanic couple test pieces were placed in the simulated oilfield sewage solution with and without the compound corrosion inhibitor. Soak at 25°C for 24 h for weight loss test. The results are shown in Table 2. After adding this compound corrosion inhibitor, the corrosion wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com