Method for treating azide ions, non-genotoxic impurity Sartan raw material medicine and immediate thereof

A genotoxic, sartan-like technology, applied in organic chemistry and other directions, can solve problems such as the generation of genotoxic impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Example 1 Preparation of Compound I-1

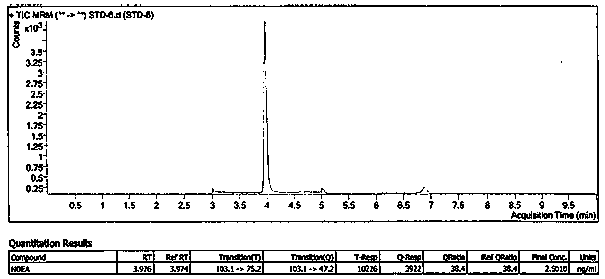

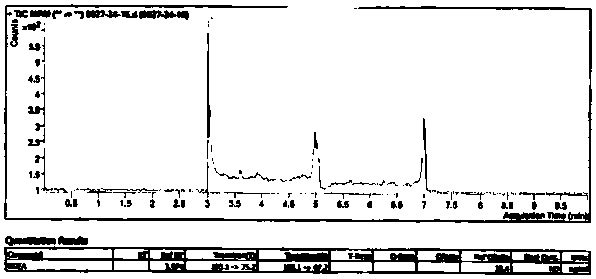

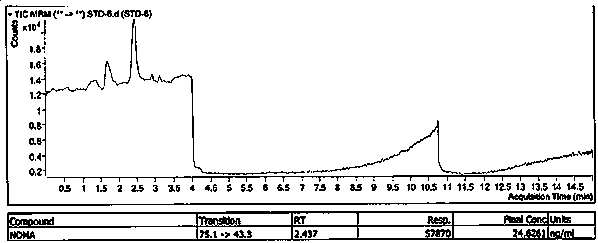

[0126] In the three-neck flask, add about 50g of compound II-1, 36g of triethylamine hydrochloride, 17g of sodium azide and 100g of toluene, stir and heat up to 100~110°C for reaction. After the reaction is completed, cool down and use 10% NaOH solution After washing, extract with 180g of water and separate liquids to obtain a water layer, add 72g of ethanol and 50% hydrogen peroxide to the water layer, slowly add hydrochloric acid dropwise, adjust the pH to 4~4.5 (the residual azide ion of the ferric chloride indicator detection system , hydrogen peroxide can be added when insufficient). Filter, wash, and dry to obtain compound I-1, yield: 86.5%, HPCL purity: 99.10%, azide: not detected, NDEA content: not detected.

Embodiment 2

[0127] Example 2 Preparation of Compound I-1

[0128] In the there-necked flask, add about 50g of compound II-1, 21g of diethylamine hydrochloride, 12g of sodium azide and 55g of toluene, stir and raise the temperature to 130°C for reaction. After the reaction, cool down and wash with 10% KOH solution , extracted with 250g of water, and separated to obtain the water layer, adjust the pH to 8~9, add 15% hydrogen peroxide to the water layer (the azide ion remains in the ferric chloride indicator detection system, hydrogen peroxide can be added when it is insufficient) After the quenching is complete, slowly add dilute hydrochloric acid dropwise to adjust the pH to 3~4. Filter, wash, and dry to obtain compound I-1, yield: 84.5%, HPCL purity: 99.12%, azide: not detected, NDEA content: not detected.

Embodiment 3

[0129] Example 3 Preparation of Compound I-1

[0130] In the three-neck flask, add about 50g of compound II-1, 62g of dimethylamine hydrochloride, 33g of sodium azide and 400g of toluene, stir and raise the temperature to 130°C for reaction. After the reaction, cool down and wash with saturated sodium bicarbonate solution Finally, extract with 300g of water, separate the liquid to obtain the water layer, adjust the pH to 5, add 70% hydrogen peroxide in the water layer, slowly add dilute hydrochloric acid, adjust the pH to be 3 ~ 4 (ferric chloride indicator detection system azide Ions remain, hydrogen peroxide can be added if insufficient), crystallization, filtration, washing, drying to obtain compound I-1, yield: 83.3%, HPCL purity 99.27%, azide: not detected, NDEA content: not Check out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com