Automobile fuel tank nut cover assembly method

An assembly method and technology for automobile fuel tanks, which are applied in the directions of power units, vehicle components, transportation and packaging to achieve the effect of preventing driving safety and personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

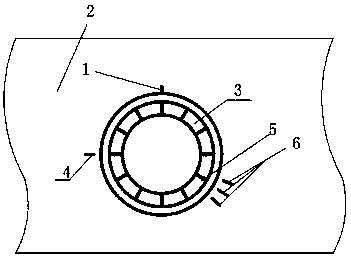

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in Figure 1, the method for assembling the automobile fuel tank nut cover according to the embodiment of the present invention differs in that:

[0018] Step A), place the fuel tank body 2 on the assembly jig;

[0019] Step B), after installing the sealing ring and the oil pump in sequence, install the nut cover 3 on the oil tank body 2;

[0020] Step C), from the starting point 1 of the fuel tank thread, rotate the nut cover 3 clockwise by hand, and align the nut cover assembly arrow 5 with the nut assembly start mark 4;

[0021] Step D), put the electric torque wrench with the set angle on the nut cover 3, and then start the electric torque wrench for automatic rotation;

[0022] Step E), when the nut assembly arrow 5 automatically rotates to the nut arrow end area formed by the nut assembly end mark 6 controlled by torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com