Hot-plug assembly used in matched mode with circuit breaker and circuit breaking arrangement

A hot-swap, circuit breaker technology, applied in coupling devices, two-component connection devices, emergency protection devices, etc., can solve the problems affecting data service quality and inconvenience in data centers, reduce plugging force, and ensure work safety. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

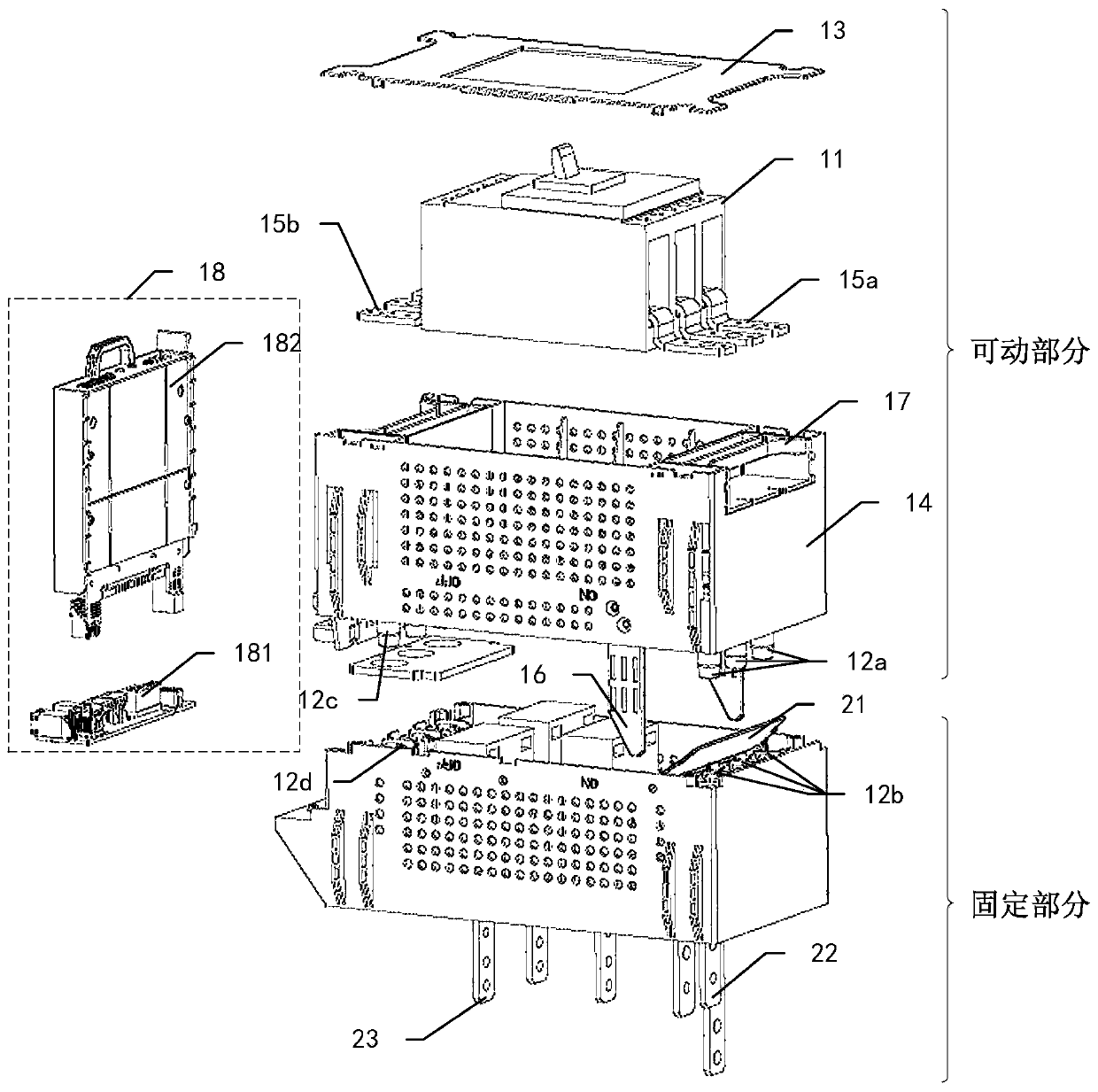

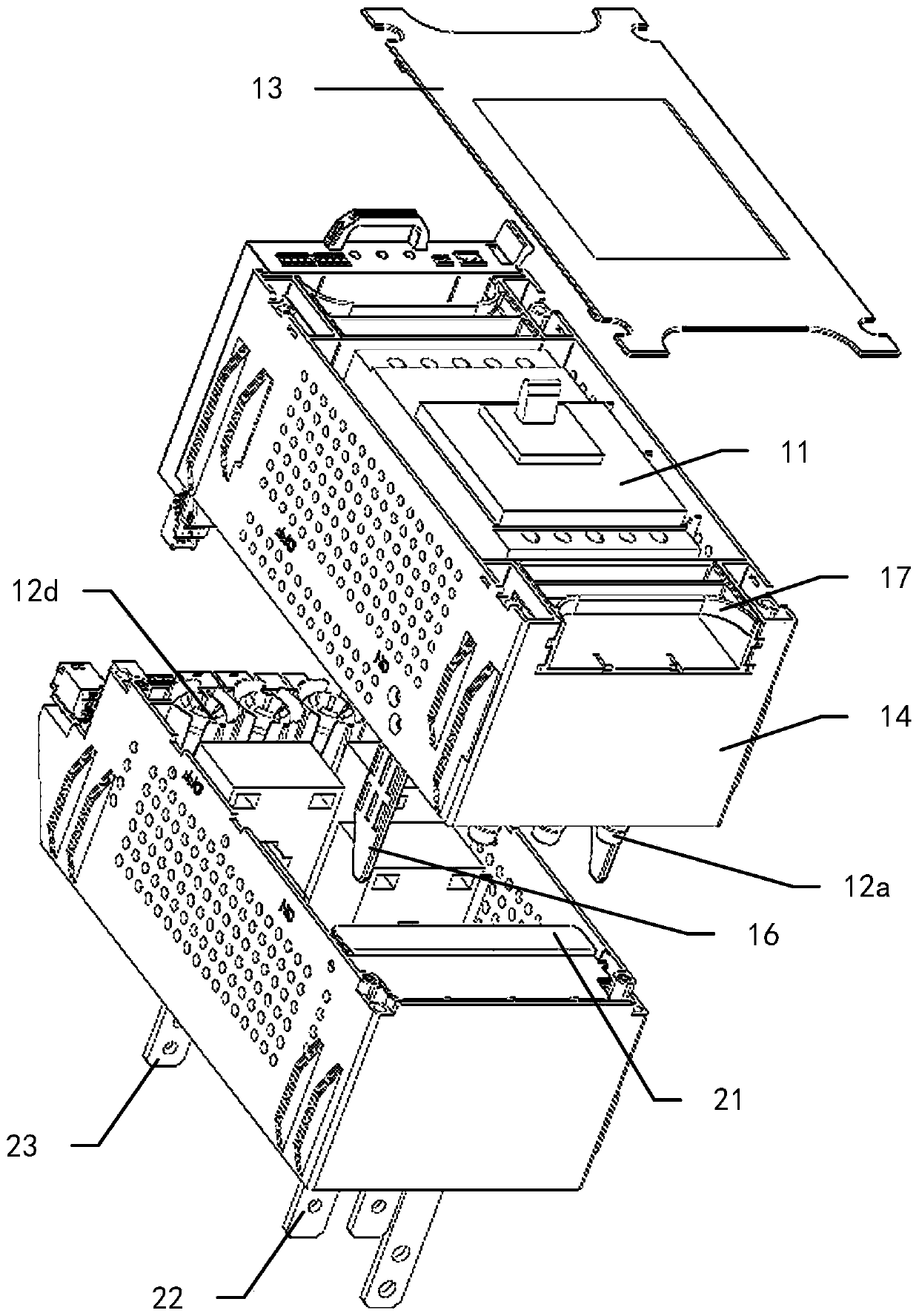

[0043] As described above, the inventors have found that when the circuit breaker of a single branch of the power distribution module in the current power supply system fails and needs to be repaired or replaced, there is often the problem of "one move will affect the whole body", and the total circuit breaker of the system needs to be disconnected. power off. The main reason is that most of the current circuit breakers are installed in a fixed way, and it is inconvenient to disassemble. Only after the entire system is powered off, maintenance personnel can smoothly and safely perform maintenance or replacement operations on the faulty circuit breaker. Apparently, this kind of maintenance method that requires the entire system to be powered off often interrupts the data services provided by the data center to users, thereby causing a lot of inconvenience to people's production and life.

[0044] In order to solve the above problems, the inventor provided a hot-swappable assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com