Automatic Summa canister sampling system

An automatic sampling and suma tank technology, applied in solar heating systems, sampling devices, mobile/directional solar collectors, etc., can solve problems such as manual tank replacement, and achieve the effect of avoiding moisture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

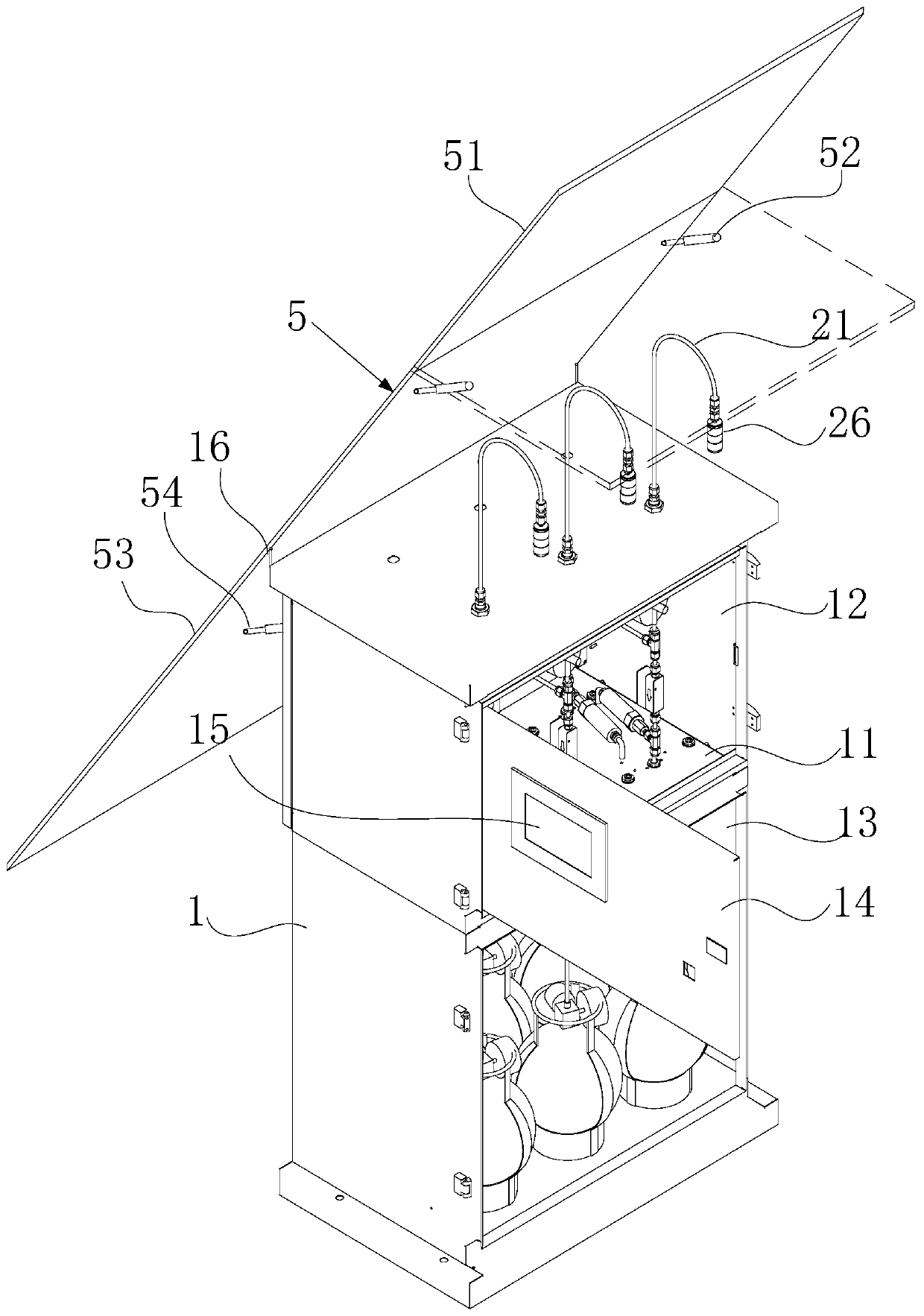

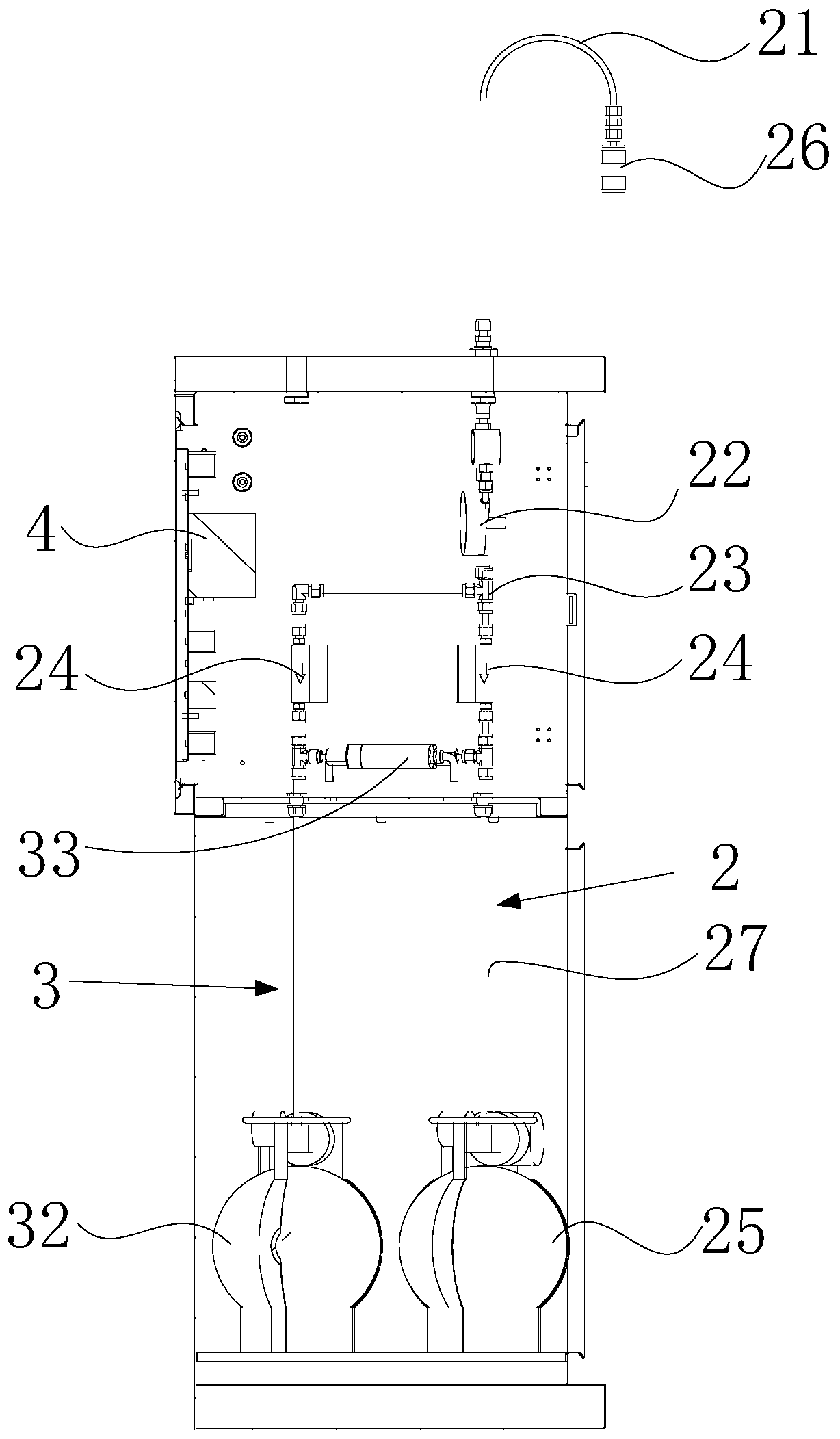

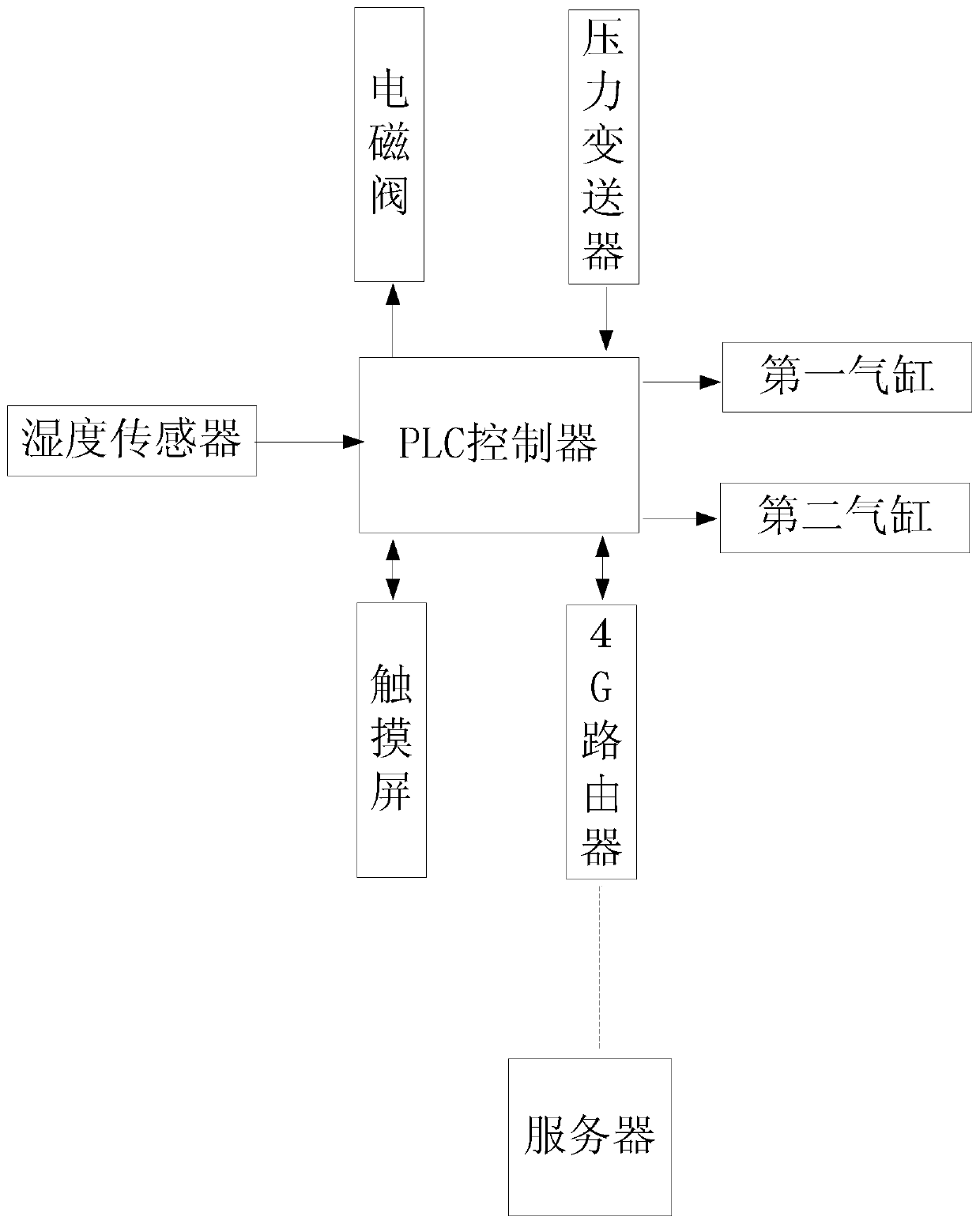

[0024] Example: such as figure 1 , figure 2 As shown, an automatic sampling system for a Suma tank includes a cabinet 1 and three sets of sampling gas circuits 2, the cabinet 1 is divided into an upper box 12 and a lower box 13 through a middle partition 11, and the upper box 12 and the lower box The box body 13 is provided with opening and closing doors 14 . Sealing adjustments are set around the opening and closing doors to prevent rainwater, dust, etc. from entering the box and corroding the internal electronic components. The sampling gas circuit 2 includes a sampling head 21, a flow limiting valve 22, a three-way valve 23, a first solenoid valve 24, and a first suma tank 25 connected in sequence through pipelines. The sampling head 21 protrudes from the top wall of the cabinet 1, A filter 26 is connected to the front end of the sampling head 21 . The flow limiting valve 22, the three-way valve 23 and the first electromagnetic valve 24 are installed in the upper box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com