Offshore wind power foundation, installation method thereof and wind generating set

A technology for wind turbines and offshore wind power, which is applied in infrastructure engineering, construction, etc., can solve the problems of high construction period and construction and installation cost, high construction cost, and increased construction period, so as to shorten construction and installation time and reduce construction and installation. cost, the effect of reducing the dynamic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

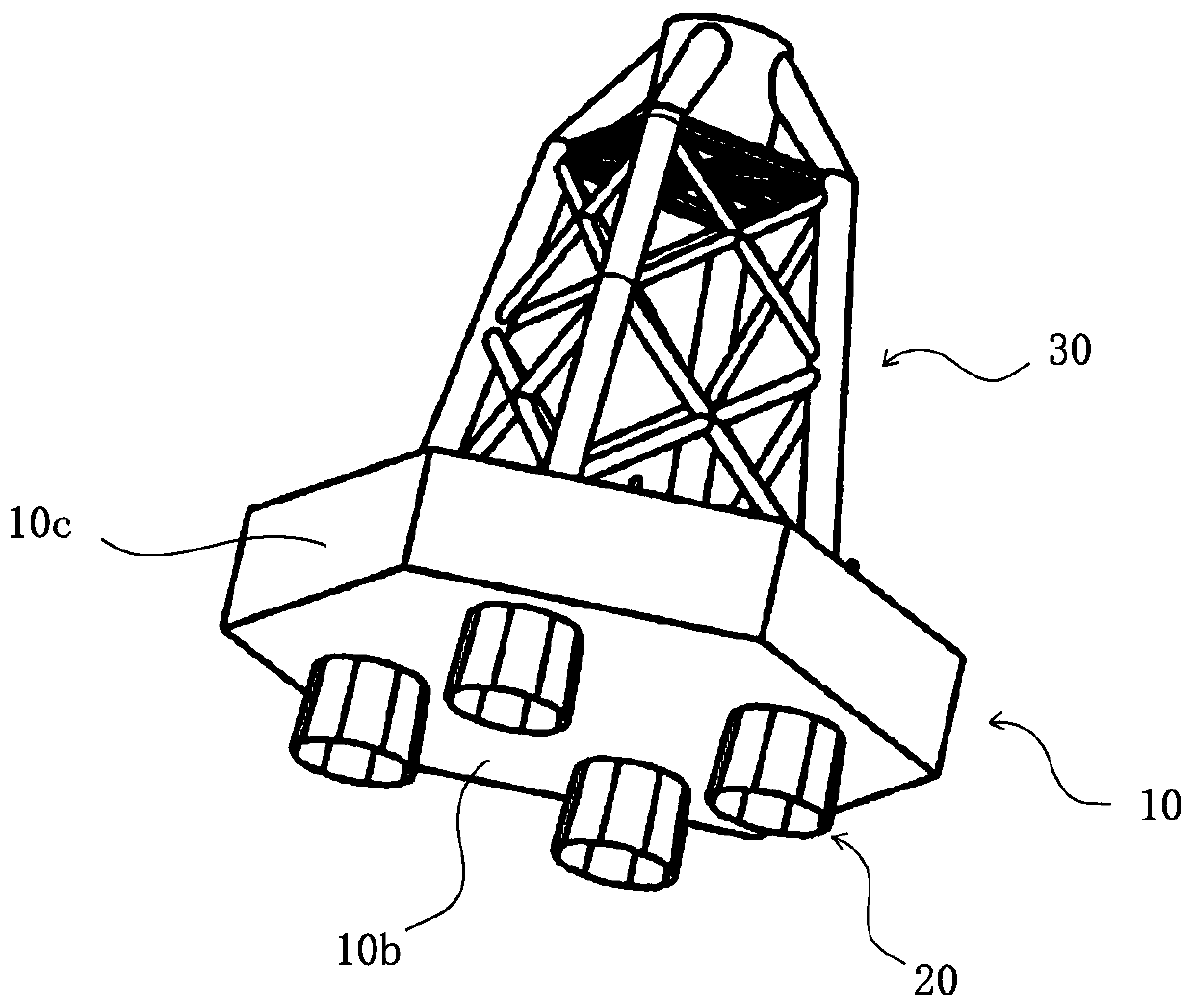

[0034] Below, will refer to Figure 1 to Figure 19 The offshore wind power foundation according to the embodiment of the present invention will be described in detail.

[0035] Such as figure 1 and figure 2 As shown, the offshore wind power foundation according to the embodiment of the present invention may include: a buoyancy tank 10, a cavity is formed inside the buoyancy tank 10, and a through hole 11 communicating with the cavity is provided on the upper surface 10a of the buoyancy tank 10; The cylinder 20, the suction cylinder 20 is arranged on the lower surface 10b of the buoyancy tank 10; the jacket 30, the jacket 30 is arranged on the upper surface of the buoyancy tank 10.

[0036] According to an embodiment of the present invention, the offshore wind power foundation may include a buoyancy tank 10 which may have a box-like structure, and a cavity is formed inside the buoyancy tank 10 . Such as figure 1 As shown, the buoyancy tank 10 may have an upper surface 10a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com