Hemp fiber corner protector and preparation method thereof

A technology of hemp fiber and hemp fiber, which is applied in the field of hemp fiber corner protection and its preparation, can solve the problems of easy damage, poor secondary utilization rate, and slow waste degradation speed, etc., and achieve high energy-saving reuse rate and wide application range , the effect of not easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

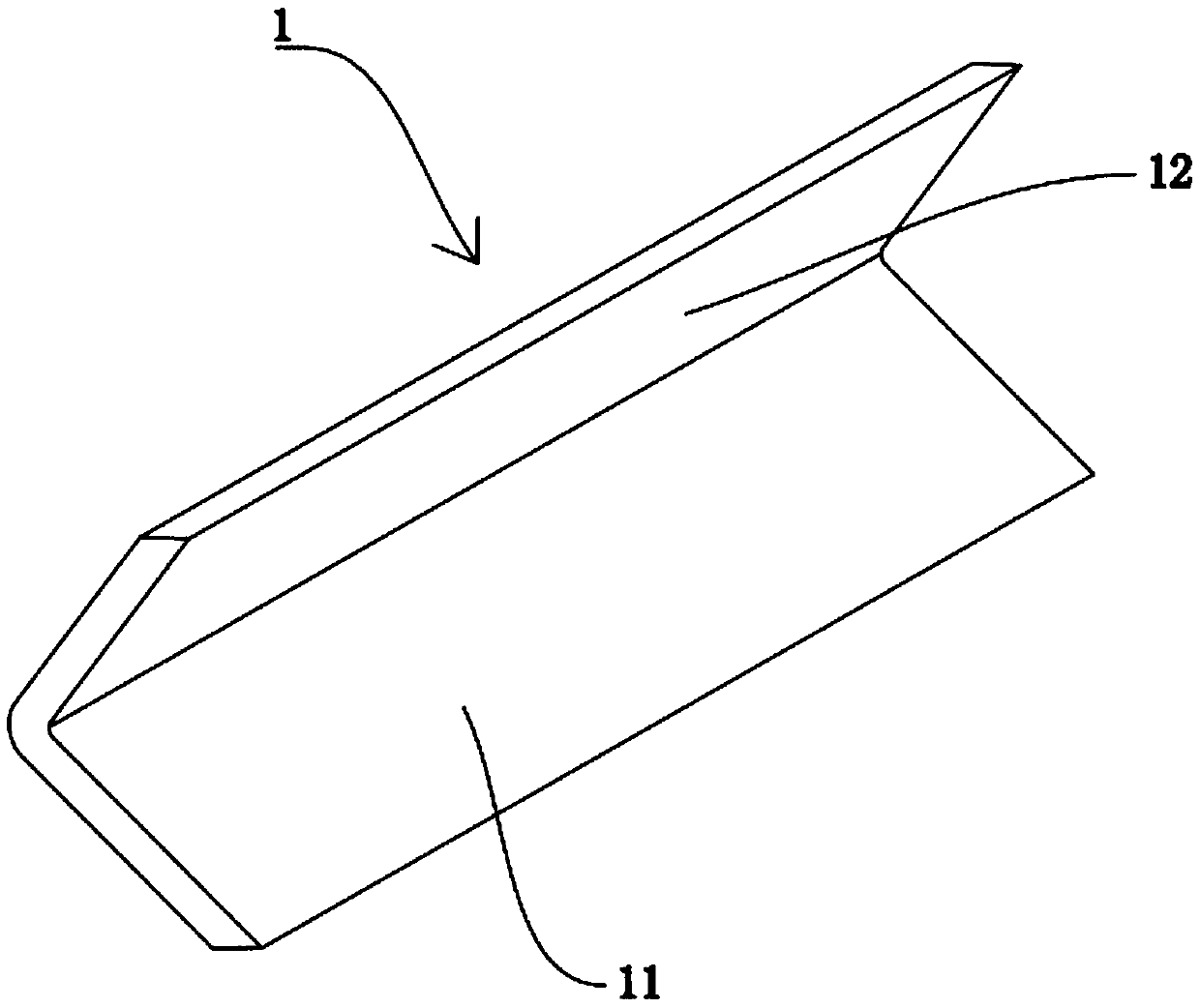

[0024] like figure 1 As shown, a hemp fiber corner protector includes a corner protector body, the corner protector body is "L" shaped, includes a first edge protector and a second edge protector, and the first edge protector and the second edge protector are connected by a long side fixed together, the first edge protection and the second edge protection are perpendicular to each other. The corner protector body is obtained by mixing hemp fiber, composite fiber filament, and non-woven fabric according to a certain weight ratio and then preheating and cold pressing. In this example, the weight ratio of hemp fiber, composite fiber filament, and non-woven fabric is 15:15: 2. The length of the hemp fiber is selected as 10mm, and the length of the composite fiber is selected as PP fiber with a length of 100mm.

[0025] The preparation method of the hemp fiber corner protector of the present embodiment comprises the steps:

[0026] 1) Weigh the raw materials according to the weig...

Embodiment 2

[0032] like figure 1 As shown, a hemp fiber corner protector includes a corner protector body, the corner protector body is "L" shaped, includes a first edge protector and a second edge protector, and the first edge protector and the second edge protector are connected by a long side fixed together, the first edge protection and the second edge protection are perpendicular to each other. The corner protector body is obtained by mixing hemp fiber, composite fiber filament and non-woven fabric according to a certain weight ratio and then preheating and cold pressing. In this example, the weight ratio of hemp fiber, composite fiber filament and non-woven fabric is 18:18: 5. The length of hemp fiber is selected as 50mm, and the length of composite fiber is selected as PP fiber with a length of 100mm.

[0033] The preparation method of the hemp fiber corner protector of the present embodiment comprises the steps:

[0034] 1) Weigh the raw materials according to the weight ratio o...

Embodiment 3

[0040] like figure 1 As shown, a hemp fiber corner protector includes a corner protector body, the corner protector body is "L" shaped, includes a first edge protector and a second edge protector, and the first edge protector and the second edge protector are connected by a long side fixed together, the first edge protection and the second edge protection are perpendicular to each other. The corner protector body is made of hemp fiber, composite fiber filament and non-woven fabric according to a certain weight ratio, which is obtained by preheating and cold pressing after mixed knitting. In this example, the weight ratio of hemp fiber, composite fiber filament and non-woven fabric is 16:18 : 2, the length of hemp fiber is selected as 10mm, and the composite fiber is selected as PP fiber with a length of 100mm.

[0041] The preparation method of the hemp fiber corner protector of the present embodiment comprises the steps:

[0042] 1) Weigh the raw materials according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com