Preparation method and application of a low-temperature sputtering α-ta coating in a large aspect ratio inner cavity

A technology with large aspect ratio and inner cavity, applied in the field of material science, can solve the problems of reducing the mechanical properties of steel materials, expensive inert gas, difficult to popularize and apply, etc. The effect of excellent corrosion performance and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using a cylindrical tantalum target with a diameter of 150mm and a large aspect ratio (13:1) inner cavity as the substrate, and a target purity of 99.99wt%, the diameter of the inner cavity with a large aspect ratio is the same as that of the target The diameter difference of the outer wall is 60mm (after adjusting the process parameters, the inner wall of the substrate can be placed within the negative glow area), and the inner cavity with a large aspect ratio is degreased and cleaned on the surface, then loaded into a cylindrical target and connected to a vacuum unit; Draw below 2×10 -2 Pa, turn on the heater, heat the surrounding of the sample to 150°C, and then pump the background vacuum to 7×10 -3 Pa. Infuse argon to 4.0×10 -1 Pa, start sputtering. The power supply used is a DC power supply, and the sputtering power density is 3.3W / cm 2 , the deposition time is 12 hours.

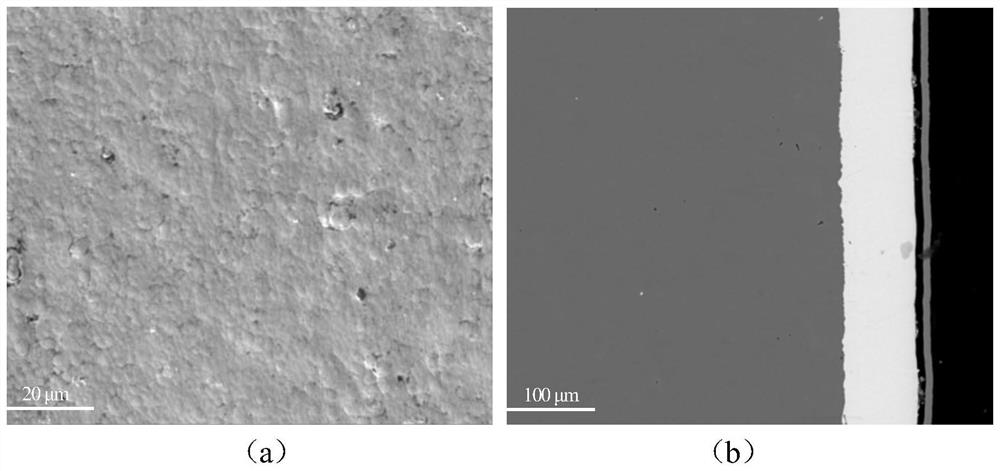

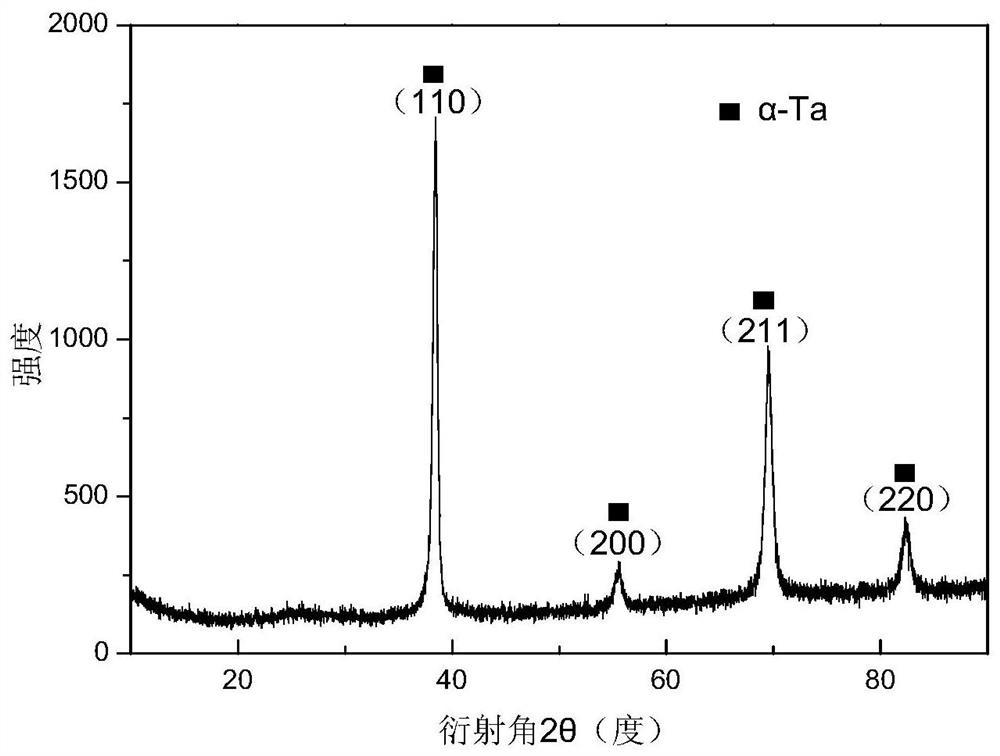

[0026] Observing the cross section and surface of the deposited tantalum coating, it can...

Embodiment 2

[0028] The inner cavity with a diameter of 150mm and a large aspect ratio (aspect ratio of 20:1) is used as the substrate, the purity of the tantalum target is 99.99wt%, and the diameter difference between the inner cavity with a large aspect ratio and the outer wall of the target is 65mm (adjust the process parameters Finally, the inner wall of the matrix can be placed within the range of the negative glow area), and the inner cavity with a large aspect ratio is degreased and cleaned on the surface, and then loaded into a cylindrical target and connected to a vacuum unit; -2 Pa, turn on the heater, heat the surrounding of the sample to 250°C, and then pump the background vacuum to 5×10 -3 Pa. Inject argon to 2.5×10 -1 Pa, start sputtering. The power supply used is a DC power supply, and the sputtering power density is 5W / cm 2 , the deposition time is 12 hours.

[0029] Observation of the cross-section and surface of the deposited tantalum coating shows that the coating ha...

Embodiment 3

[0031] The inner cavity with a diameter of 125mm and a large aspect ratio (aspect ratio of 15:1) is used as the substrate, the purity of the tantalum target is 99.99wt%, and the diameter difference between the inner cavity with a large aspect ratio and the outer wall of the target is 55mm (adjust the process parameters Afterwards, the inner wall of the matrix can be placed within the scope of the negative glow area), the inner wall of the barrel is degreased and cleaned, and then loaded into a cylindrical target and connected to a vacuum unit; the inner wall of the barrel is vacuumed to less than 3×10 -2 Pa, turn on the heater, heat the surrounding of the sample to 200°C, and then pump the background vacuum to 4×10 - 3 Pa. Inject argon to 6.0×10 -1 Pa, start sputtering. The power supply used is a DC power supply, and the sputtering power density is 2.6W / cm 2 , a deposition time of 4 hours.

[0032] Observation of the cross-section and surface of the deposited tantalum coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap