Keratin-base bamboo charcoal modified dye powder and method for preparing same

A keratin and bamboo charcoal technology, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve problems such as difficulty in applying dyes, and achieve the effects of improving binding force, moderate adsorption, and improving adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

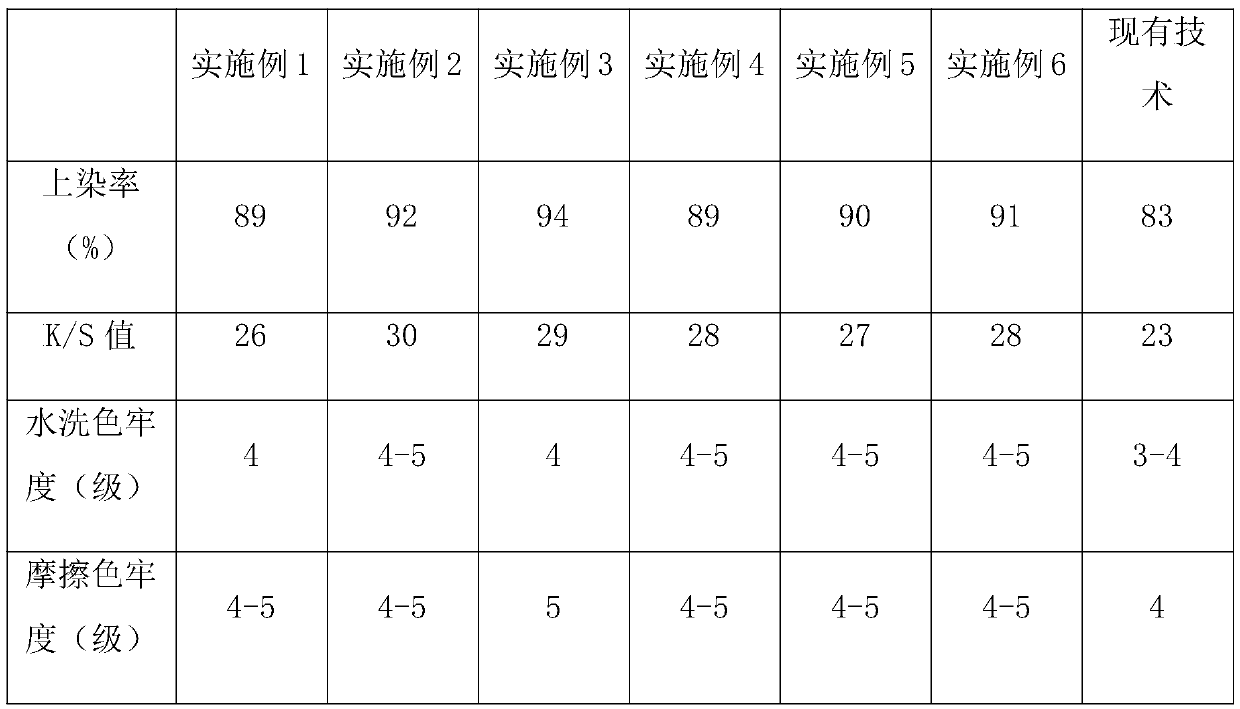

Examples

Embodiment 1

[0026] (1) Using bamboo chips as raw materials, boil and soften them in 15g / mL lye at 98°C for 30 minutes, wash them thoroughly, place them in 20U / g pectinase solution, and vibrate enzymatically at 35°C and 800Hz frequency In 1 hour, a preliminary porous bamboo sheet is obtained, in which the hole size of the preliminary porous bamboo sheet is 0.5 mm, and the proportion of unconnected sizes is 30%.

[0027] (2) According to the mass ratio of the porous bamboo sheet to the keratin of 1.6:1, the porous bamboo sheet is immersed in the keratin solution, taken out, steamed at 125°C for 60 minutes, and dried to obtain keratin The first modified porous bamboo sheet.

[0028] (3) The initial product of keratin-modified porous bamboo chip was heated to 420°C at a rate of 5°C / min for 45 minutes, and then heated to 500°C at a rate of 3°C / min, and held for 60 minutes. The temperature is lowered to 100°C at a rate of 20°C / min, naturally lowered to room temperature, and fully ground to obtain m...

Embodiment 2

[0031] (1) Using bamboo chips as raw materials, boil and soften at 100°C for 45 minutes in 20g / mL lye, wash thoroughly, place in 25U / g pectinase solution, and vibrate enzymatically at 40°C and 1600Hz frequency After 4 hours, a preliminary porous bamboo sheet was obtained, in which the hole size of the preliminary porous bamboo sheet was 13 mm, and the proportion of unconnected sizes was 45%.

[0032] (2) According to the mass ratio of the porous bamboo sheet to the keratin of 3:1, the porous bamboo sheet is immersed in the keratin solution, taken out, steamed at 130°C for 90 minutes, and dried to obtain keratin The first modified porous bamboo sheet.

[0033] (3) The initial product of keratin-modified porous bamboo chip was heated to 440°C at a rate of 10°C / min for 60 minutes in a nitrogen atmosphere, and then heated to 600°C at a rate of 5°C / min for 90 minutes. The temperature is lowered to 120°C at a rate of 30°C / min, naturally lowered to room temperature, and fully ground to o...

Embodiment 3

[0036] (1) Using bamboo chips as raw material, boil and soften at 99℃ for 35min in 16g / mL lye, wash thoroughly, place in 22U / g pectinase solution, and vibrate enzymatically at 38℃ and 1200Hz frequency After 2 hours, a preliminary porous bamboo sheet was obtained, in which the hole size of the preliminary porous bamboo sheet was 5 mm, and the proportion of unconnected sizes was 38%.

[0037] (2) According to the mass ratio of the porous bamboo sheet to the keratin of 1.9:1, the porous bamboo sheet was immersed in the keratin solution, taken out, steamed at 129°C for 70 minutes, and dried to obtain keratin The first modified porous bamboo sheet.

[0038] (3) The initial product of keratin-modified porous bamboo chip was heated to 435°C at a rate of 6°C / min for 50 minutes in a nitrogen atmosphere, and then heated to 550°C at a rate of 4°C / min for 70 minutes. The temperature is lowered to 105°C at a rate of 27°C / min, naturally lowered to room temperature, and fully ground to obtain mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com