Process for treating alkaline malachite green wastewater on basis of coagulation sedimentation methods

A technology of coagulation sedimentation and wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problem of low treatment efficiency of alkaline green wastewater and improve treatment efficiency. , The effect of improving the removal rate of lead and improving the solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

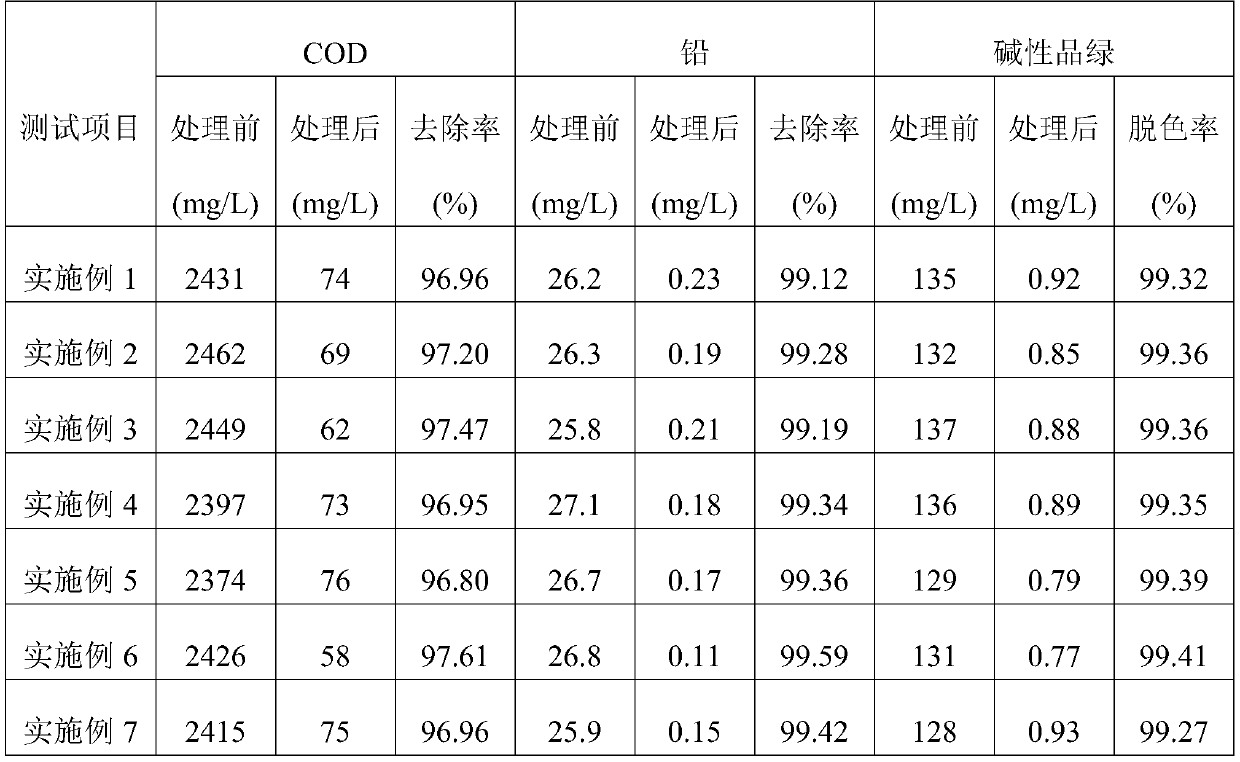

Examples

Embodiment 1

[0031] A kind of technology based on coagulation sedimentation method to process alkaline magenta waste water, comprises the following steps:

[0032] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0033] S1, adding a decolorizing agent to the alkaline magenta wastewater to be treated for decolorizing treatment, the amount of the decolorizing agent added is 1 mg / L, to obtain a decolorized treatment solution;

[0034] S2. After precipitating the decolorized waste water obtained in step S1 for 30 minutes, add iron powder in an amount of 0.7 mg / L, stir under aeration conditions, stir for 1 hour, stop aeration and stirring, and let stand for 4 hours , to obtain the waste water after standing;

[0035] S3. Add an acid-base regulator to the standing wastewater obtained in step S2 to adjust the pH value of the wastewater to 6-6.5;

[0036] S4, add flocculant to the wastewater that has adjusted the pH value obtained i...

Embodiment 2

[0040] A kind of technology based on coagulation sedimentation method to process alkaline magenta waste water, comprises the following steps:

[0041] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0042] S1, adding a decolorizing agent to the alkaline magenta wastewater to be treated for decolorizing treatment, the amount of the decolorizing agent added is 1.2 mg / L, to obtain a decolorized treatment solution;

[0043] S2, after the decolorized waste water obtained in step S1 was precipitated for 30min, iron powder was added in an amount of 1mg / L, stirred under aeration conditions, stirred for 1 hour, and the stirring speed was 120r / min, and the aeration and Stir, stand still for 5 hours, obtain the waste water after standing;

[0044] S3. Add an acid-base regulator to the standing wastewater obtained in step S2 to adjust the pH value of the wastewater to 6-6.5;

[0045] S4, adding a flocculant to the wastewat...

Embodiment 3

[0049] A kind of technology based on coagulation sedimentation method to process alkaline magenta waste water, comprises the following steps:

[0050] S0, pretreatment: filter the alkaline magenta wastewater to be treated to remove impurities in the wastewater;

[0051] S1, adding a decolorizing agent to the alkaline magenta wastewater to be treated for decolorization treatment, the addition of the decolorizing agent is 1.3mg / L to obtain a decolorized treatment solution;

[0052] S2. After precipitating the decolorized waste water obtained in step S1 for 30 minutes, add iron powder in an amount of 1.2 mg / L, stir under the condition of aeration, stir for 1 hour, and the stirring speed is 130 r / min, stop the aeration And stir, leave standstill 5 hours, obtain the waste water after standing;

[0053] S3. Add an acid-base regulator to the standing wastewater obtained in step S2 to adjust the pH value of the wastewater to 6-6.5;

[0054] S4, add flocculant to the wastewater that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com