Sound prompting cover, pipe body and container

A lid and sound technology, which is used in the direction of tightly closing containers with lids, bottle/container caps, capping, etc., can solve problems such as thread failure to open, difficulty, etc., to avoid damage to threads, and to avoid problems that are difficult to rotate and open. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

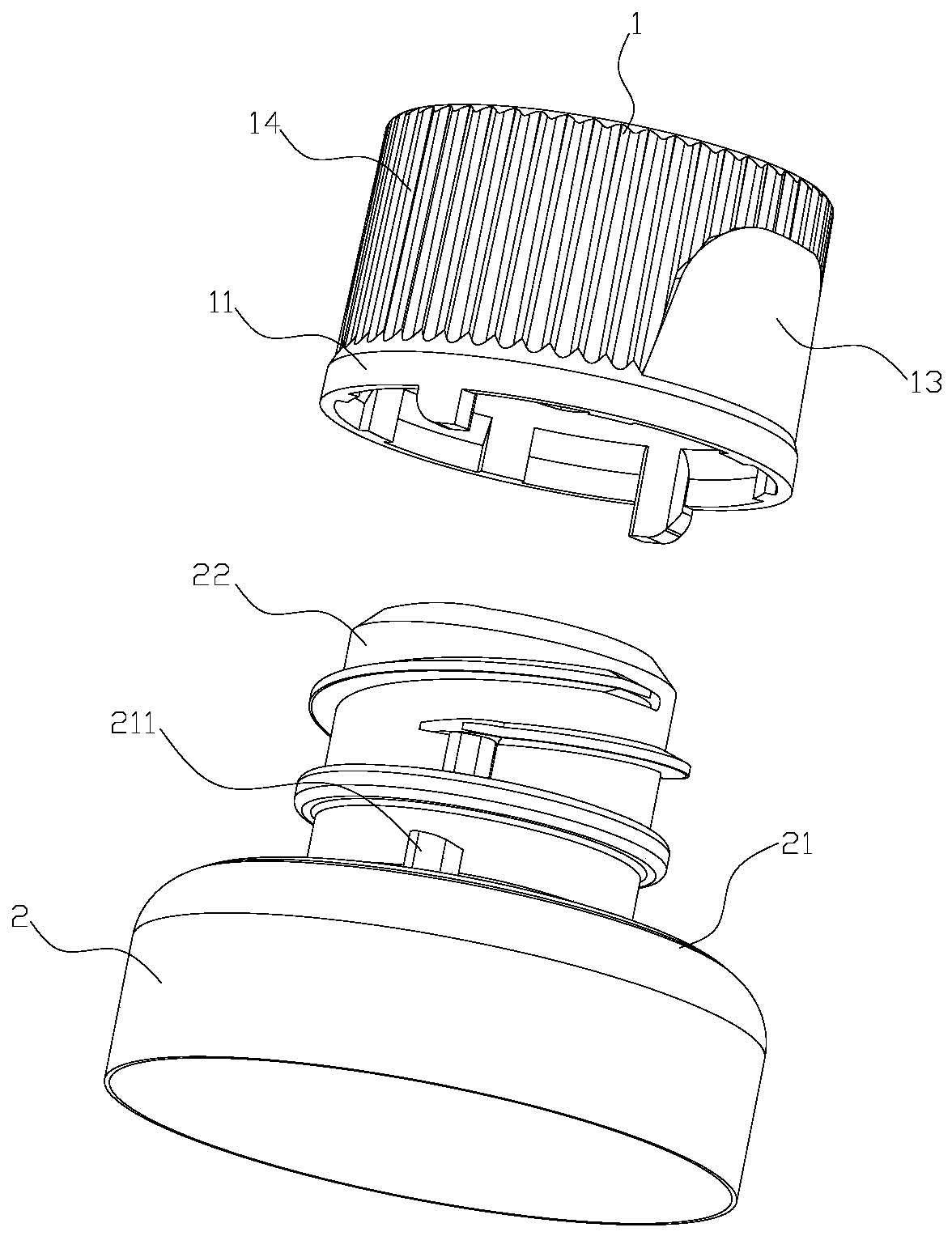

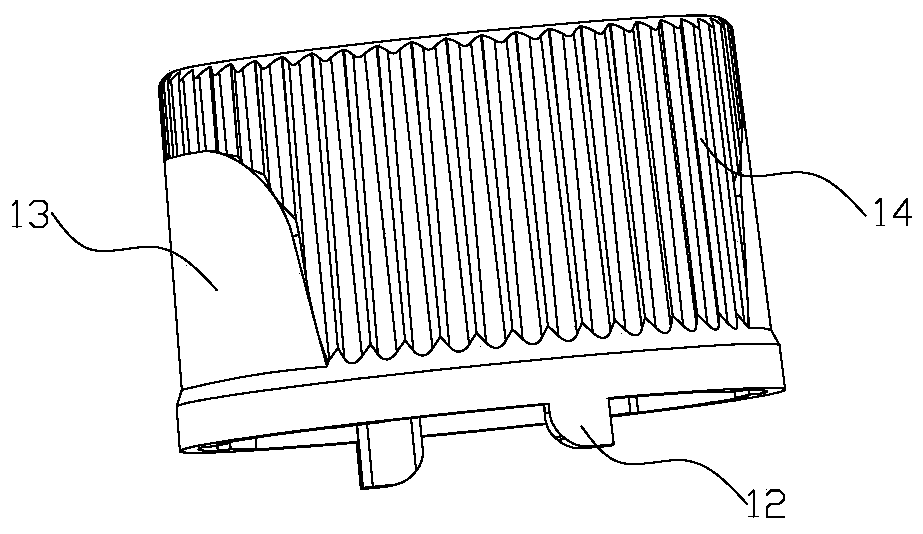

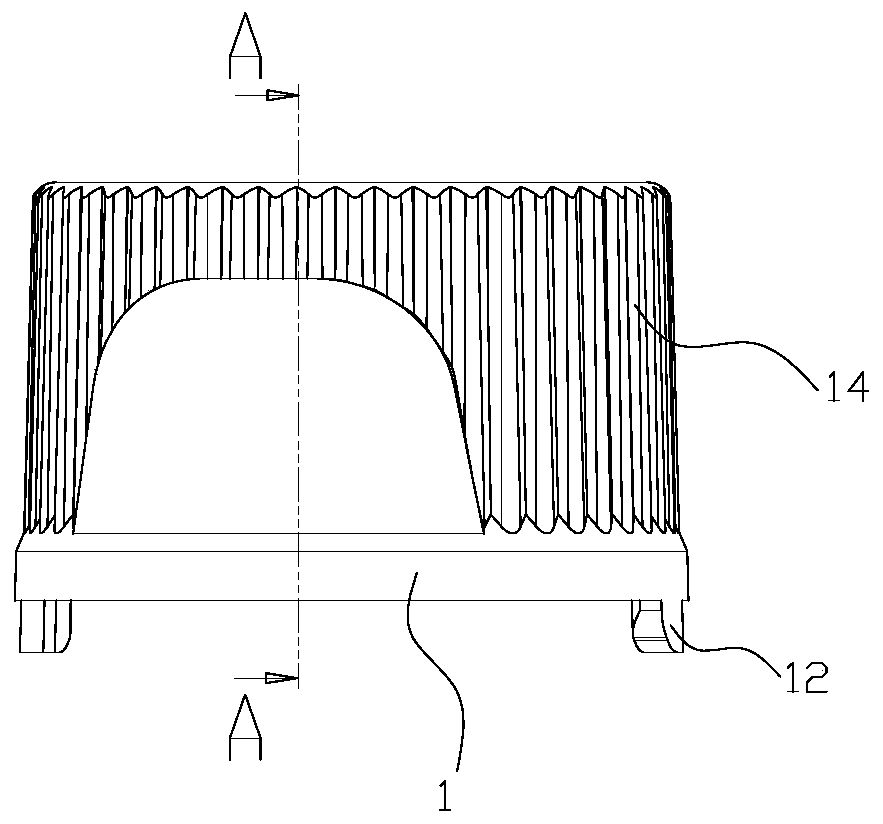

[0042] Such as figure 1 Shown is a container according to one embodiment of the present invention. The container includes a sound prompting cover 1 and a tube body 2, and the sound prompting cover 1 and the tube body 2 are connected by threads.

[0043] The sound prompt cover 1 includes a cover body 11 and a lock foot 12 provided on the cover body 11 , and the lock foot 12 is used to engage the anti-rotation mechanism 211 on the tube body 2 . Correspondingly, the tube body 2 includes a tube shoulder 21 and a discharge nozzle 22 disposed on the tube shoulder 21 , and the discharge nozzle 22 communicates with the inside of the tube body 2 for extruding the contents. An anti-rotation mechanism 211 is also provided on the pipe shoulder 21 .

[0044] When the container is locked, the cover body 11 rotates relative to the tube body 2 , and thus the locking foot 12 rotates relative to the anti-rotation mechanism 211 . When the lock pin 12 rotates to the anti-rotation mechanism 211...

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 is that the first double thread 15 and the second double thread 221 are replaced by a single thread lead structure. The single thread lead structure also has the function of locking the cover body 11 and maintaining the overall airtightness of the container. In other embodiments, the first double thread 15 and the second double thread 221 can also be replaced by a three-thread or four-thread lead structure, which has a similar effect.

Embodiment 3

[0060] The difference between embodiment 3 and embodiment 1 lies in that the number of locking feet 12 and anti-rotation mechanisms 211 is two pairs. The two pairs of locking feet 12 are offset by 90° and are disposed on the lower opening edge of the cover body 11 . The two pairs of anti-rotation mechanisms 211 are misaligned by 90° and are disposed on the tube shoulder 21 . The arrangement of two pairs of locking legs 12 and two pairs of anti-rotation mechanisms 211 can further increase functions such as prompting sound and preventing the cover body from loosening by itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com