A method and device for automatic welding of galvanometer laser-hot wire composite pipelines

A composite pipe and automatic welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as weld defects, poor fusion of groove side walls and weld metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

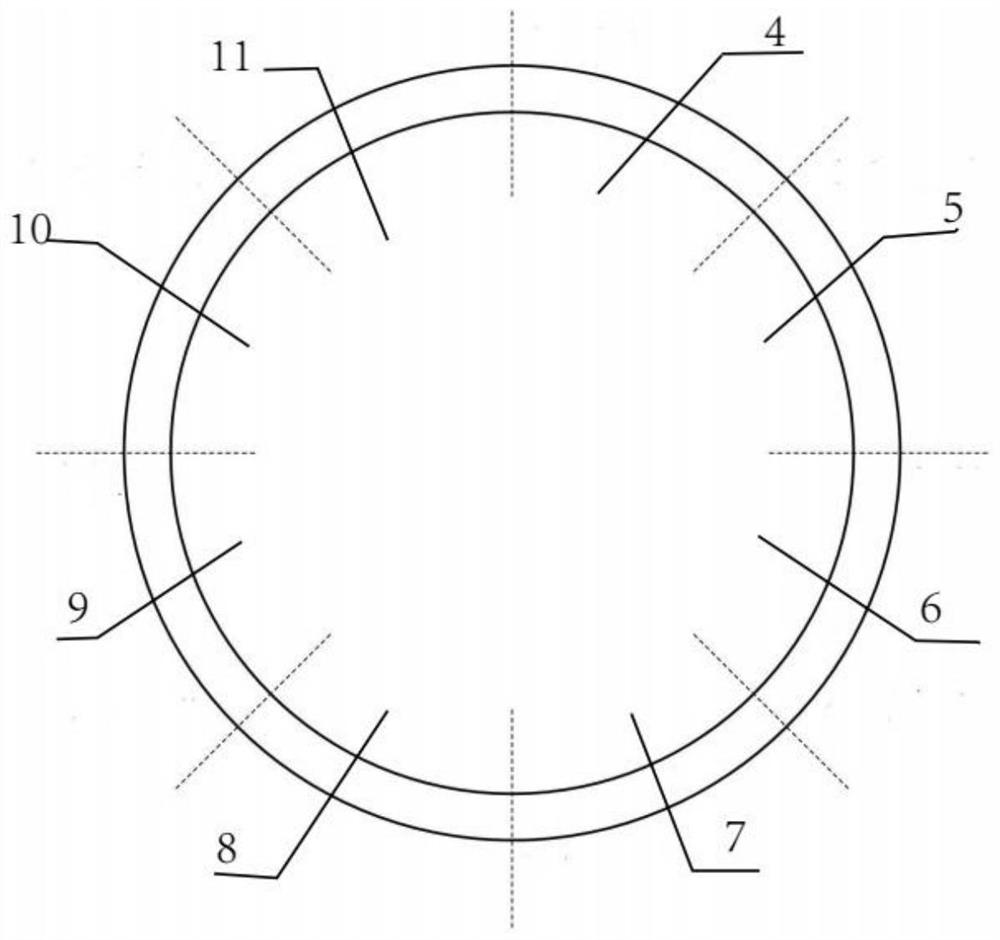

[0039]The 316LN stainless steel pipe with a diameter of 600 mm and a wall thickness of 70 mm is welded by using the galvanometer laser-hot wire TIG composite pipe automatic welding welding technology in this embodiment. The specific experimental method is as follows:

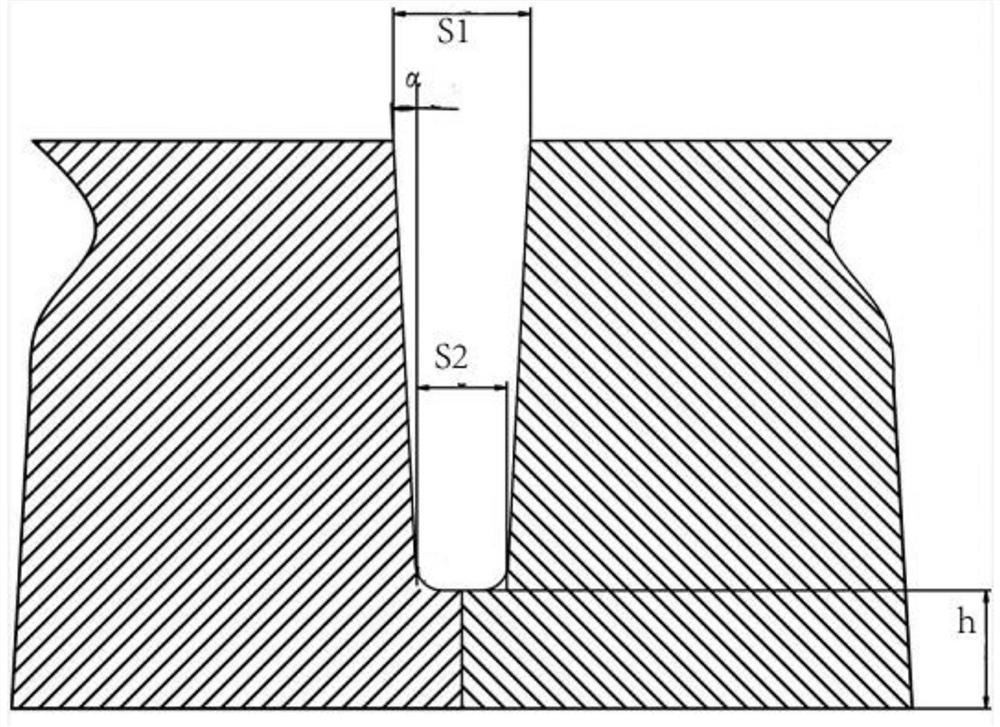

[0040] (1) After the pipes are butted before welding, a combined groove is made. The width S2 of the bottom of the groove is 8mm, the width S1 of the top is 15mm, the angle α of the side wall of the groove is 3°, the thickness h of the blunt edge at the bottom of the groove is 10mm, and the blunt edge The gap is less than 2mm; the shape of the groove and the position of all parameters are as follows image 3 shown;

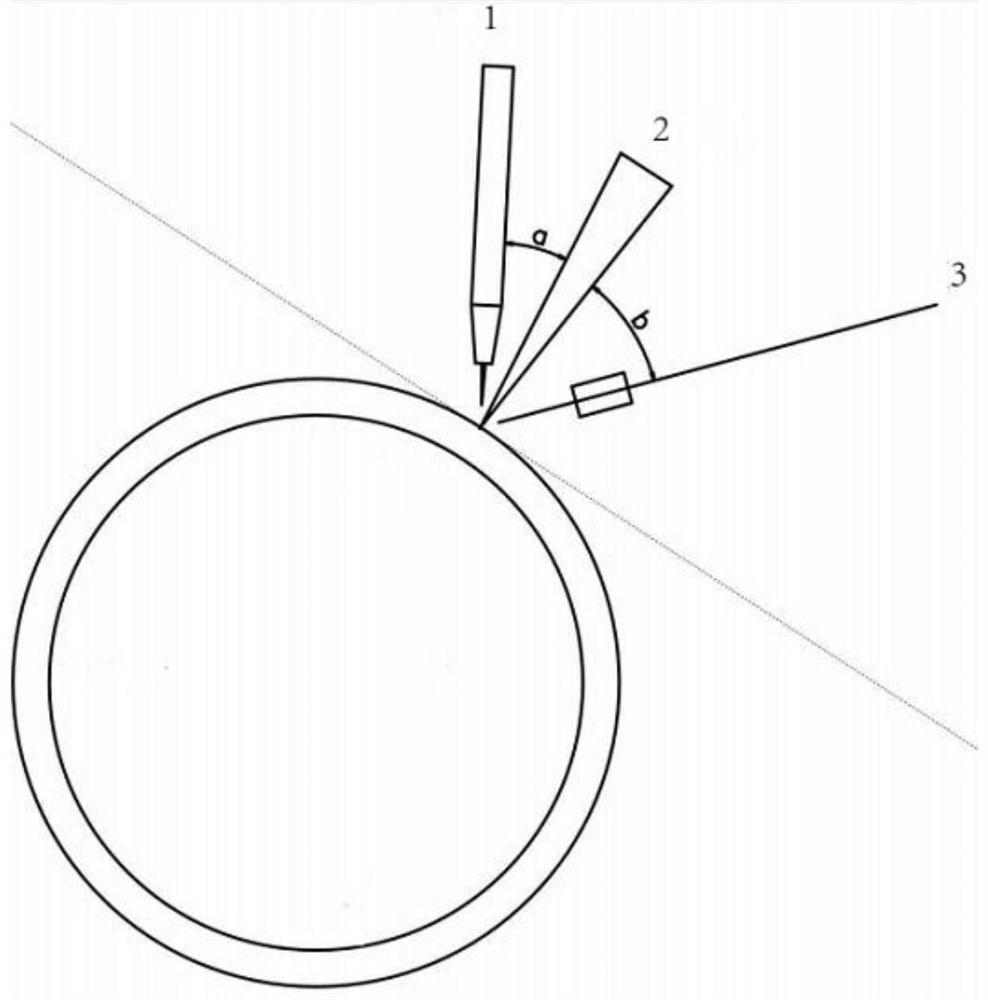

[0041] (2) The welding device is composed of the laser head and the TIG welding torch 1 side shaft and is rigidly connected with the movable trolley. The angle a between the laser beam and the TIG welding torch is adjusted in advance to be 30°, and the laser spot size is 0.6mm. Adjust the laser beam...

Embodiment 2

[0056] The 316L stainless steel pipe with a diameter of 400 mm and a wall thickness of 30 mm is welded by using the galvanometer laser-hot wire TIG composite pipe automatic welding technology in this embodiment. The specific experimental method is as follows:

[0057] (1) After the pipes are butted before welding, a combined groove is made. The width S2 of the bottom of the groove is 8mm, the width S1 of the top is 11mm, the angle α of the side wall of the groove is 3°, the thickness h of the blunt edge at the bottom of the groove is 5mm, and the blunt edge The gap is less than 2mm;

[0058] (2) The welding device is composed of the laser head and the TIG welding torch 1 side shaft and is rigidly connected with the movable trolley. The angle a between the laser beam and the TIG welding torch is adjusted in advance to be 30°, and the laser spot size is 0.5mm. Adjust the laser beam The swing range is -2mm~+2mm, and the protective gas is argon;

[0059] (3) Weld the blunt edge o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com