Film forming device and film forming method

A film forming device and metal film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of substrate wrinkles, temperature difference, etc., and achieve the effect of suppressing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0034] (Structure of Film Formation Device)

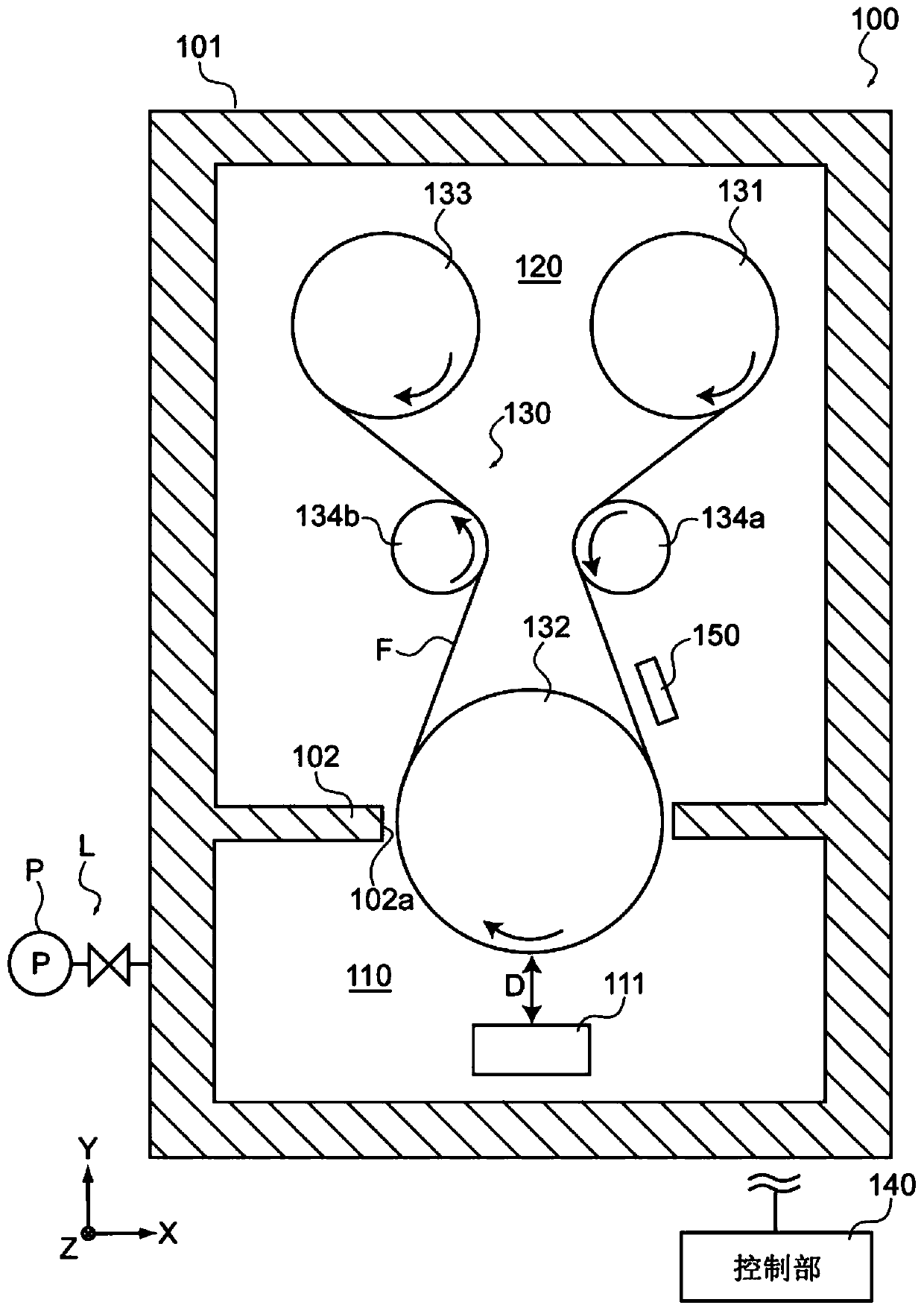

[0035] figure 1 It is a schematic side sectional view showing the structure of the film formation apparatus 100 according to one embodiment of the present invention. figure 1 The illustrated X-axis, Y-axis, and Z-axis directions represent three mutually orthogonal axial directions, the X-axis and Y-axis represent the horizontal direction, and the Z-axis direction represents the vertical direction.

[0036] Such as figure 1 As shown, the film forming apparatus 100 has a vacuum chamber 101 , a film forming unit 110 , a transport unit 120 , a transport mechanism 130 , a control unit 140 , and a preheating unit 150 .

[0037] The vacuum chamber 101 has an airtight structure, and is connected to an exhaust line L having a vacuum pump P. Thus, the vacuum chamber 101 is configured to be able to evacuate the interior to a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com