A kind of ternary cathode material and preparation method thereof

A positive electrode material, graphene technology, applied in the field of ternary positive electrode materials and its preparation, can solve the problems of cycle performance decline, powder resistivity increase, etc., achieve the effect of reducing powder resistivity, obvious effect, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

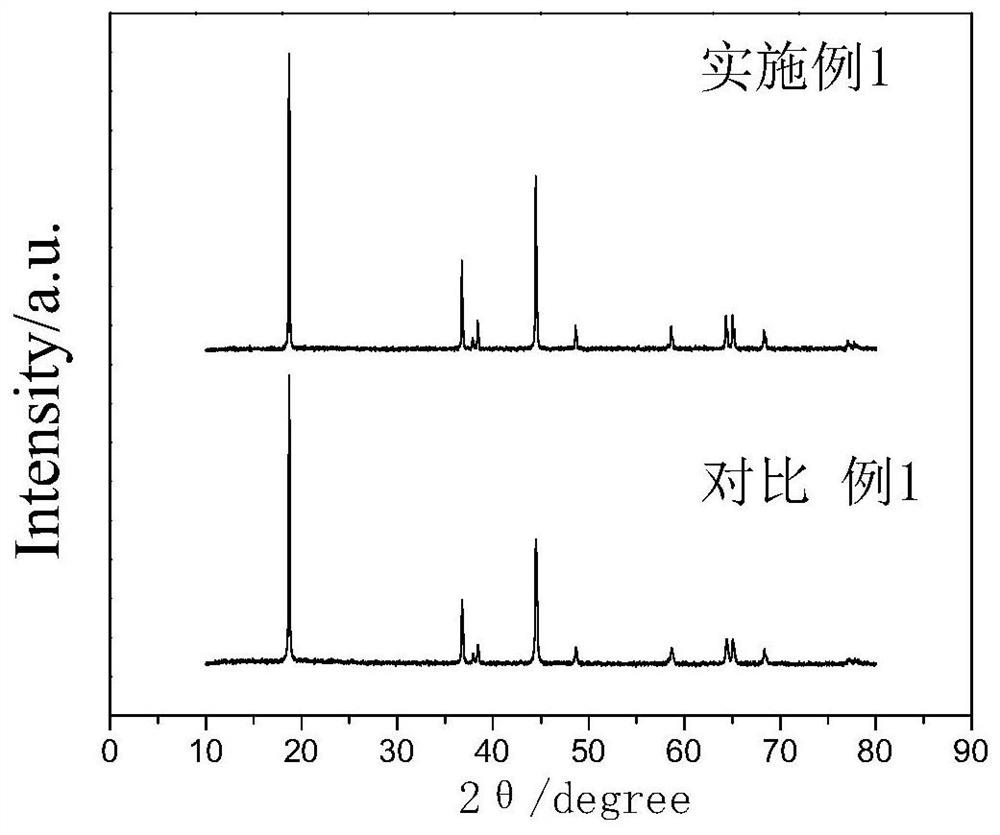

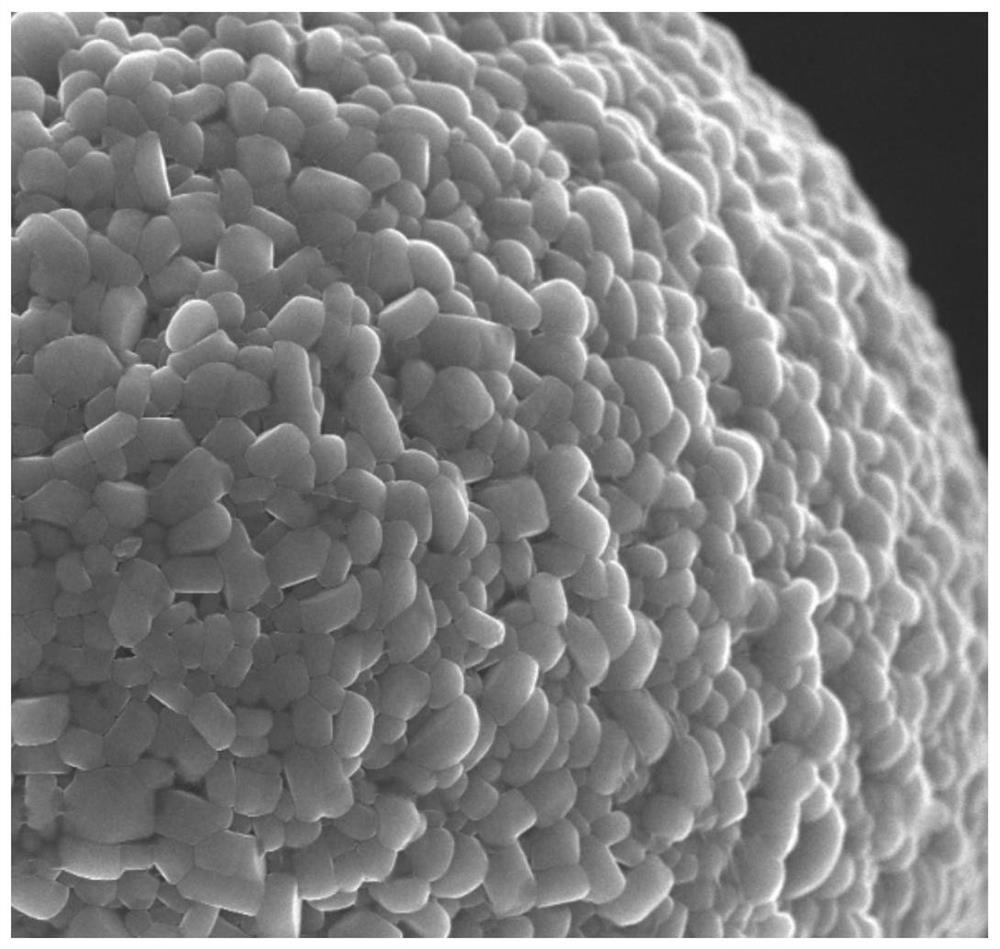

[0033] The ternary cathode material described in Example 1 and Comparative Example 1 is Li n Ni 1-x-y co x mn y o 2 , wherein 0<x<0.5, 0<y<0.5, 0.9<n<1.5, preferably NMC811.

[0034] The size of the graphene oxide described in Example 1 is 0.2 μm, the number of layers is 3 layers, C:O=1.9, and the concentration of the graphene oxide solution is 2 g / L.

[0035] Example 1

[0036] A preparation method of a ternary cathode material, comprising the steps of:

[0037] (1) Add ternary positive electrode material and deionized water according to the ratio of material to water ratio of 2:1 in the washing process, and add 0.0016% (based on graphene oxide weight, the mass ratio to ternary positive electrode material is 0.0016%) graphite oxide Graphene solution, stirred in water washing equipment at a stirring speed of 80r / min for 30min, so that graphene oxide is uniformly and fully coated on the surface of the ternary positive electrode material;

[0038] (2) After the ternary po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com