Preparation method for lithium iron phosphate/graphene composite material with uniformly-dispersed graphene

A lithium iron phosphate and composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of difficult graphene dispersion, large specific surface area, and difficulty in uniform dispersion of dry powder ball milling, and achieve Coulombic efficiency improvement, Simple process and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

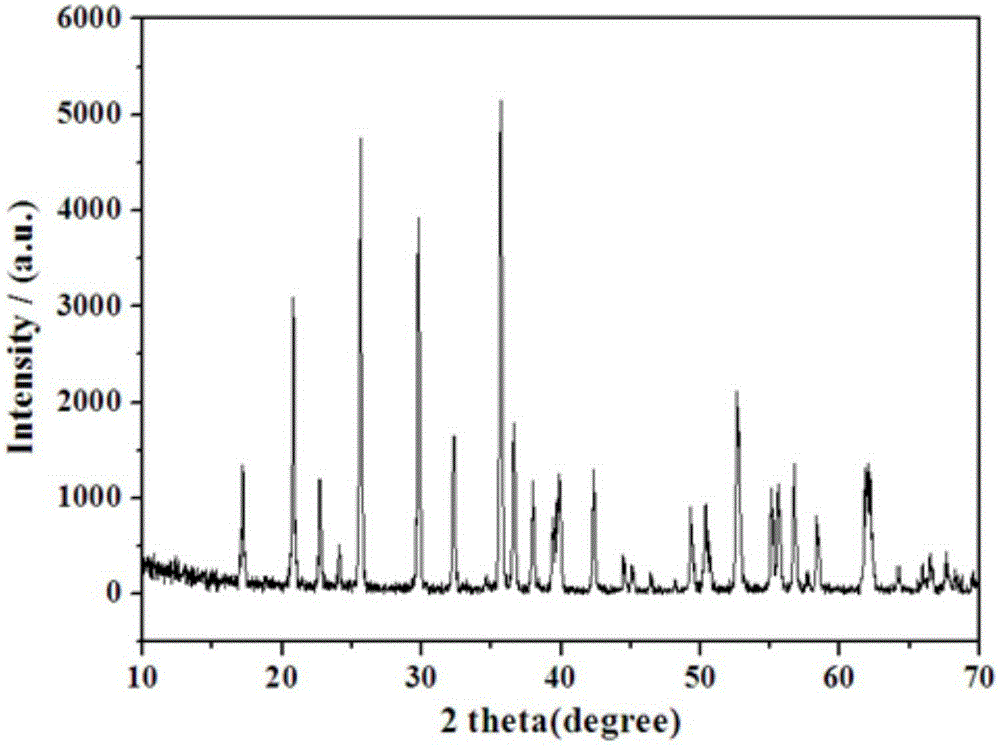

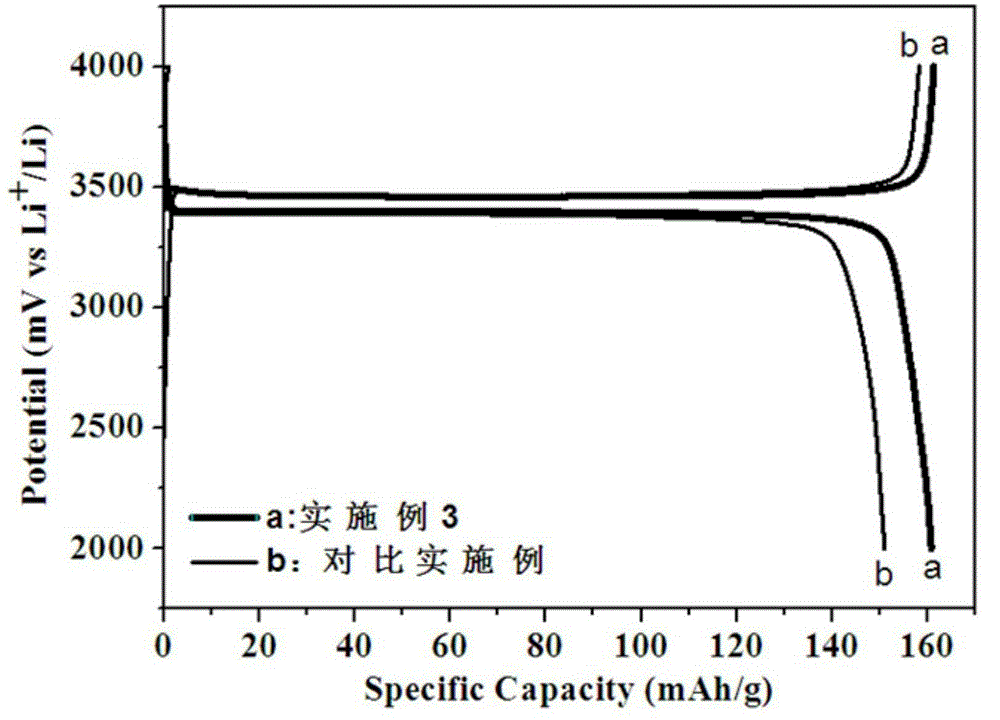

Image

Examples

Embodiment 1

[0021] (1) according to the PVP mass fraction is 0.5% to take by weighing PVP and be dissolved in deionized water to prepare the PVP solution, then according to the molar ratio Li:Fe=0.98:1 to take by weighing an appropriate amount of ferric phosphate raw material and lithium carbonate to join in the PVP solution, control The solid content of the slurry is 45%, and it is added into a stirring mill for grinding and stirring treatment to obtain a lithium iron phosphate precursor slurry.

[0022] (2) Weigh an appropriate amount of water-soluble chitosan and dissolve it in a PVP solution with a mass fraction of 0.5% to obtain a chitosan and PVP blend solution. Wherein the mass concentration of chitosan is 0.5%, then take appropriate amount of graphene powder and join in above-mentioned chitosan, PVP solution, control the mass concentration of graphene to be 3%, promptly obtain graphene slurry after ultrasonic dispersion .

[0023] (3) Both the lithium iron phosphate precursor slu...

Embodiment 2

[0027] (1) according to PVA mass fraction is 1.5% to take by weighing PVA and be dissolved in deionized water to prepare PVA solution, then according to molar ratio Li:Fe=1.0:1 take by weighing an appropriate amount of iron phosphate raw material and Lithium Hydroxide to join in the PVA solution, Control the solid content of the slurry to 35%, add it into a stirring mill, and perform grinding and stirring treatment to obtain a lithium iron phosphate precursor slurry.

[0028] (2) Weigh an appropriate amount of water-soluble chitosan, dissolve it in a PVA solution with a mass fraction of 1.5%, and obtain a chitosan-PVA blend solution. Wherein the mass concentration of chitosan is 1.0%, then take appropriate amount of graphene powder and join in above-mentioned chitosan, PVA solution, control the mass concentration of graphene to be 3.5%, promptly obtain graphene slurry after ultrasonic dispersion .

[0029] (3) Both the lithium iron phosphate precursor slurry and the graphene ...

Embodiment 3

[0033] (1) according to PVP mass fraction is 2.0% to take by weighing PVP and be dissolved in deionized water and prepare PVP solution, then according to molar ratio Li:Fe=1.01:1 take by weighing an amount of ferric phosphate raw material and lithium carbonate and join in the PVP solution, control The solid content of the slurry is 40%, and it is added into a stirring mill for grinding and stirring treatment to obtain a lithium iron phosphate precursor slurry.

[0034] (2) Weighing an appropriate amount of water-soluble chitosan and dissolving it in a PVP solution with a mass fraction of 2.0% to obtain a chitosan and PVP blend solution. Wherein the mass concentration of chitosan is 1.5%, then take appropriate amount of graphene powder and join in above-mentioned chitosan, PVP solution, control the mass concentration of graphene to be 4.5%, promptly obtain graphene slurry after ultrasonic dispersion .

[0035] (3) Both the lithium iron phosphate precursor slurry and the graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com