Grain depot intelligent ventilation system

A technology for ventilation systems and grain depots, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve problems such as moldy grains and affect grain quality, and achieve the effect of reducing air inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

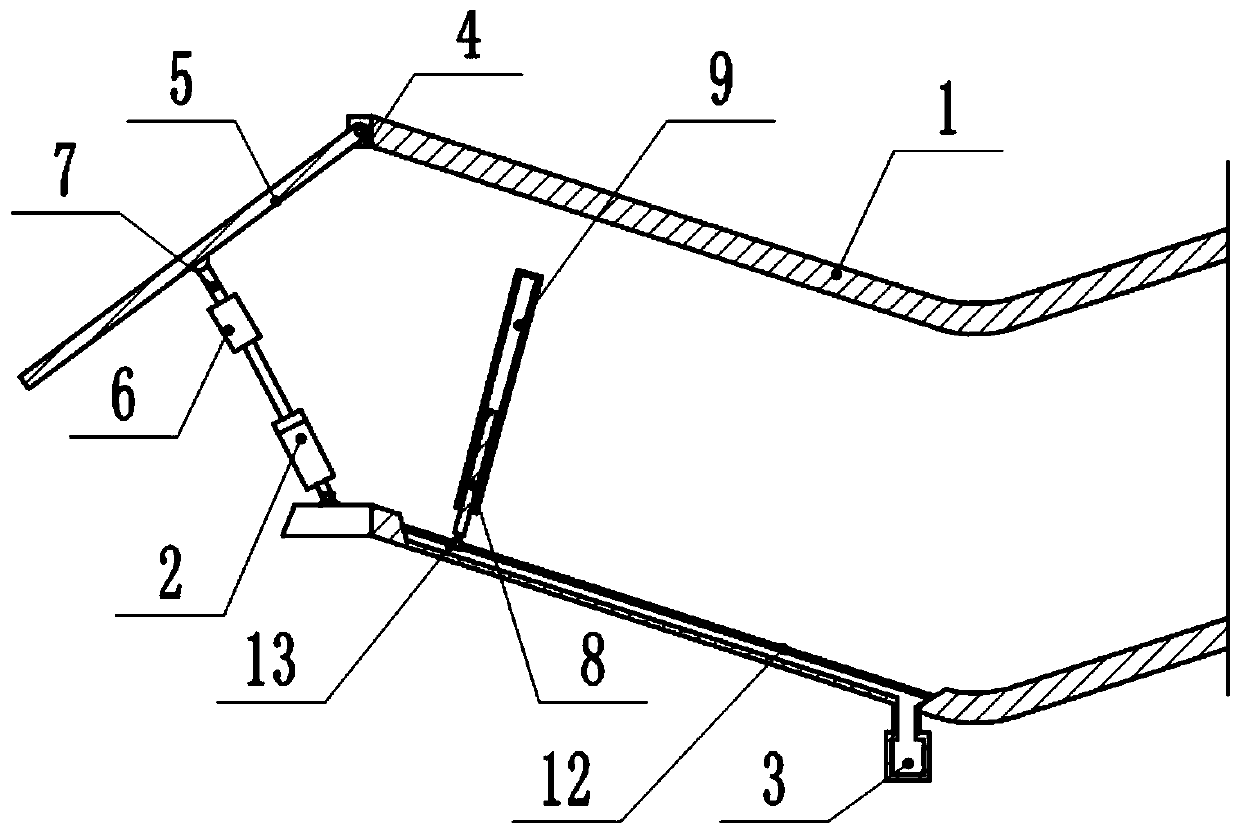

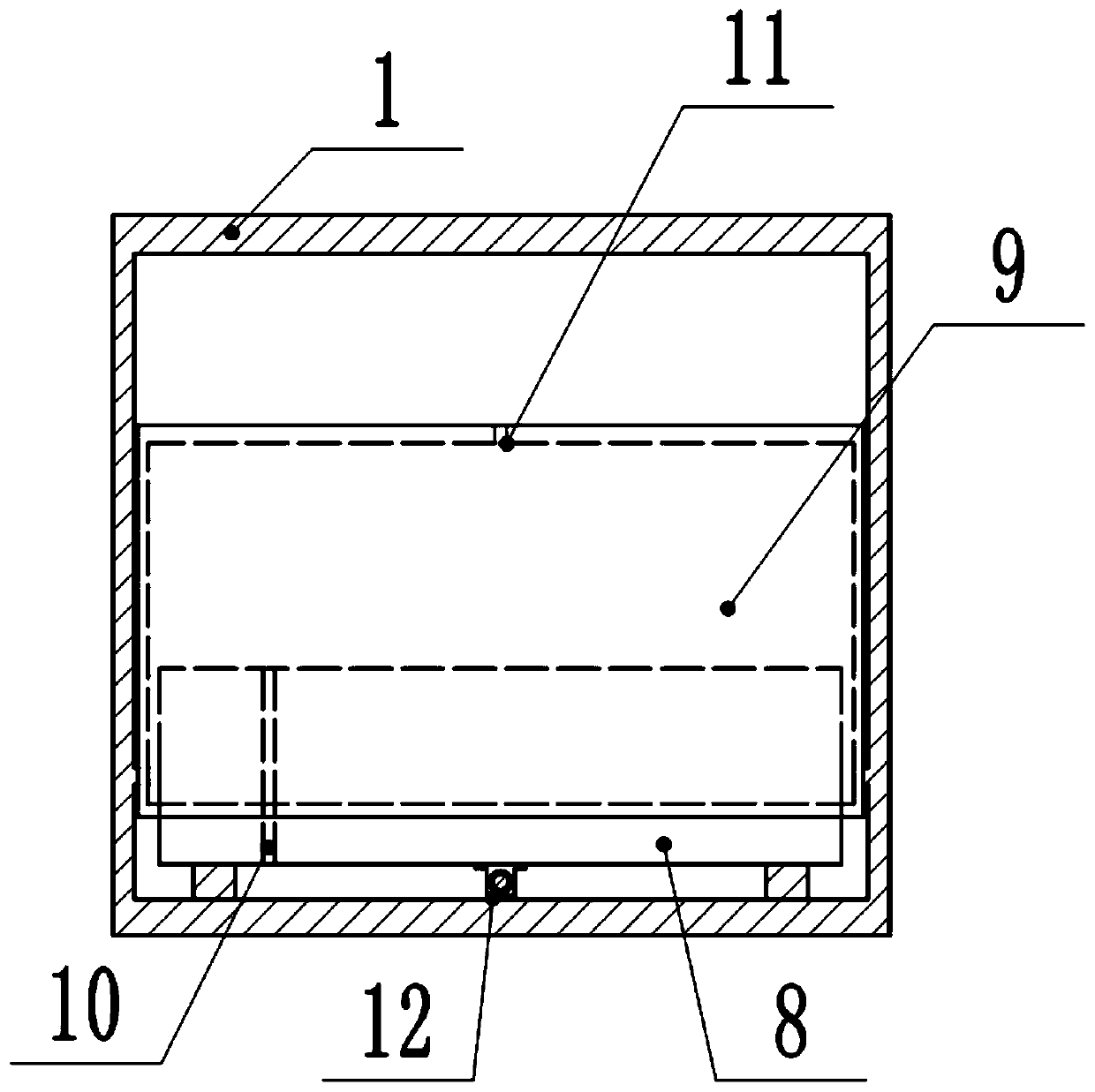

[0046] The intelligent ventilation system of the grain depot includes: an external detection unit, an internal detection unit, a control unit, a main control server, a driving rod 2, a first driving motor, a ventilation window door 5 and an air intake unit;

[0047] Such as image 3 As shown, the external detection unit includes a temperature sensor and a humidity sensor embedded in the outside of the ventilation door and window, and the external temperature sensor and humidity sensor are used to detect the temperature and humidity information outside the ventilation window door 5 respectively;

[0048] The temperature sensor is a GTS200 temperature sensor, which senses temperature quickly, measures temperature accurately, and is waterproof; the humidity sensor is a DS1629S humidity sensor;

[0049] The control unit includes an external communication module and a drive module, the drive module, the external temperature sensor and the humidity sensor are all wired to the external...

Embodiment 2

[0065] The grain depot intelligent ventilation system differs from the first embodiment in that it also includes: a second drive motor, a reversing button group, a generator, a rectifier and a ball screw 12;

[0066] The generator has a protruding rotating shaft, and one end of the connecting shaft is welded to the protruding end of the generator rotating shaft; the inner wall of the descending section of the ventilation pipe 1 is provided with a chute along the air intake direction, and the lower part of the inner baffle 8 is embedded in the chute; the ball screw 12 Including screw mandrel 12 and threaded connection on the screw mandrel 12 to convert the screw mandrel 12 rotary motion into linear motion nut 13; The screw mandrel 12 is installed in the chute, the second driving motor is provided with a drive shaft, one end of the drive shaft is connected with the wire One end of the rod 12 is welded; the lower end of the inner baffle 8 is welded to the nut 13; the direction in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com