A Muffle Furnace Used for Determination of Ash Content in Coal Samples

An ash content measurement and muffle furnace technology, which is applied in muffle furnaces, furnaces, cooking furnaces, etc., can solve the problems of non-use of test data, insufficient speed, deflagration, etc., to improve measurement accuracy, reduce reactions, and reduce sulfuric acid. Effect of salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

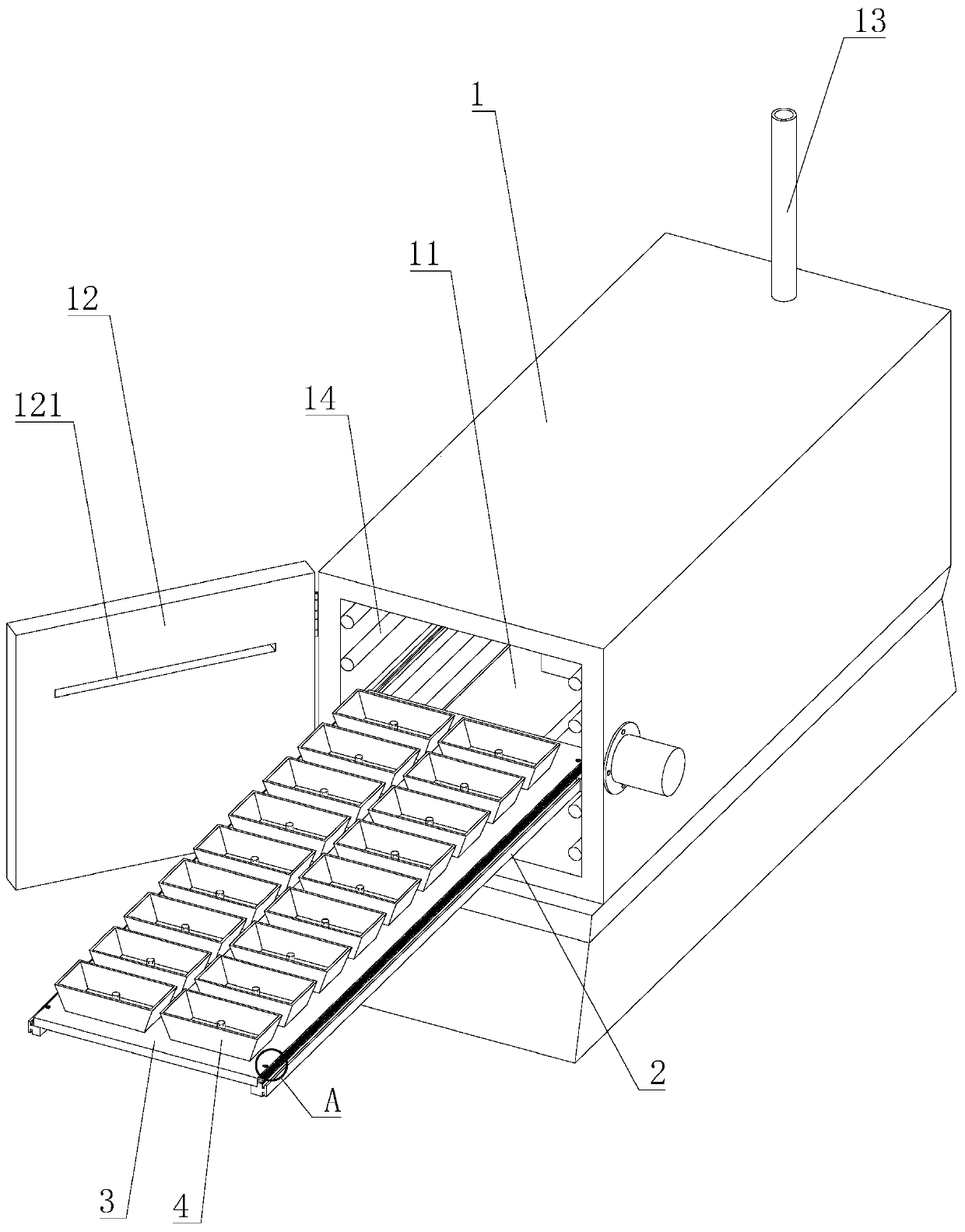

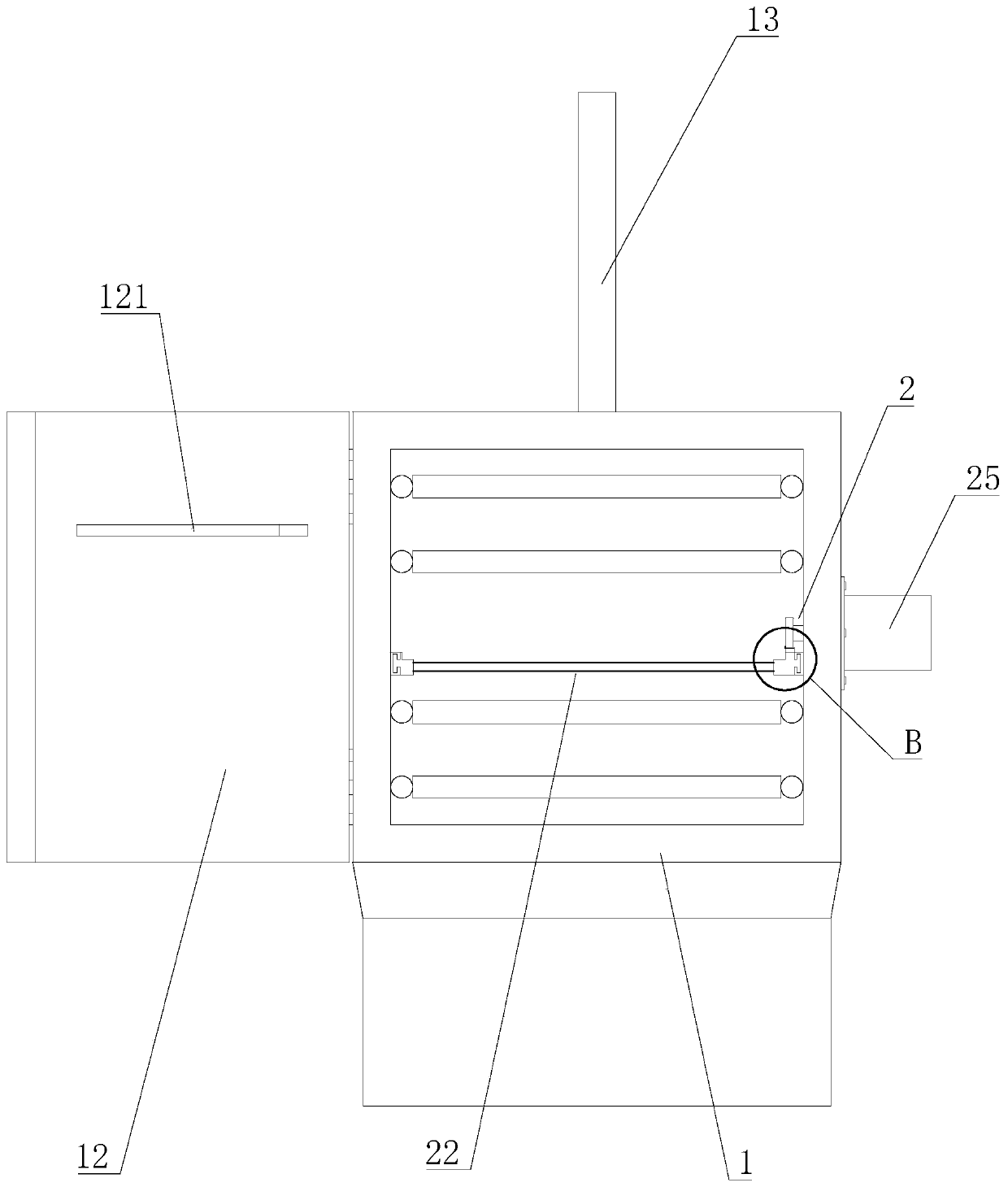

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] Participate in figure 1 And attached image 3, a muffle furnace for coal sample ash determination, comprising a furnace body 1 with a furnace chamber 11, a furnace door 12 hingedly mounted on the furnace body 1, and a chimney 13 arranged on the top of the furnace body 1 and communicating with the furnace chamber 11. Wherein, heaters are provided on the left side wall, right side wall and rear side wall of the furnace 11. In this embodiment, the heaters are a plurality of electric heating tubes 14, and the plurality of heating tubes are arranged in the furnace at intervals along the height direction. 11 on the left side wall, right side wall and rear side wall.

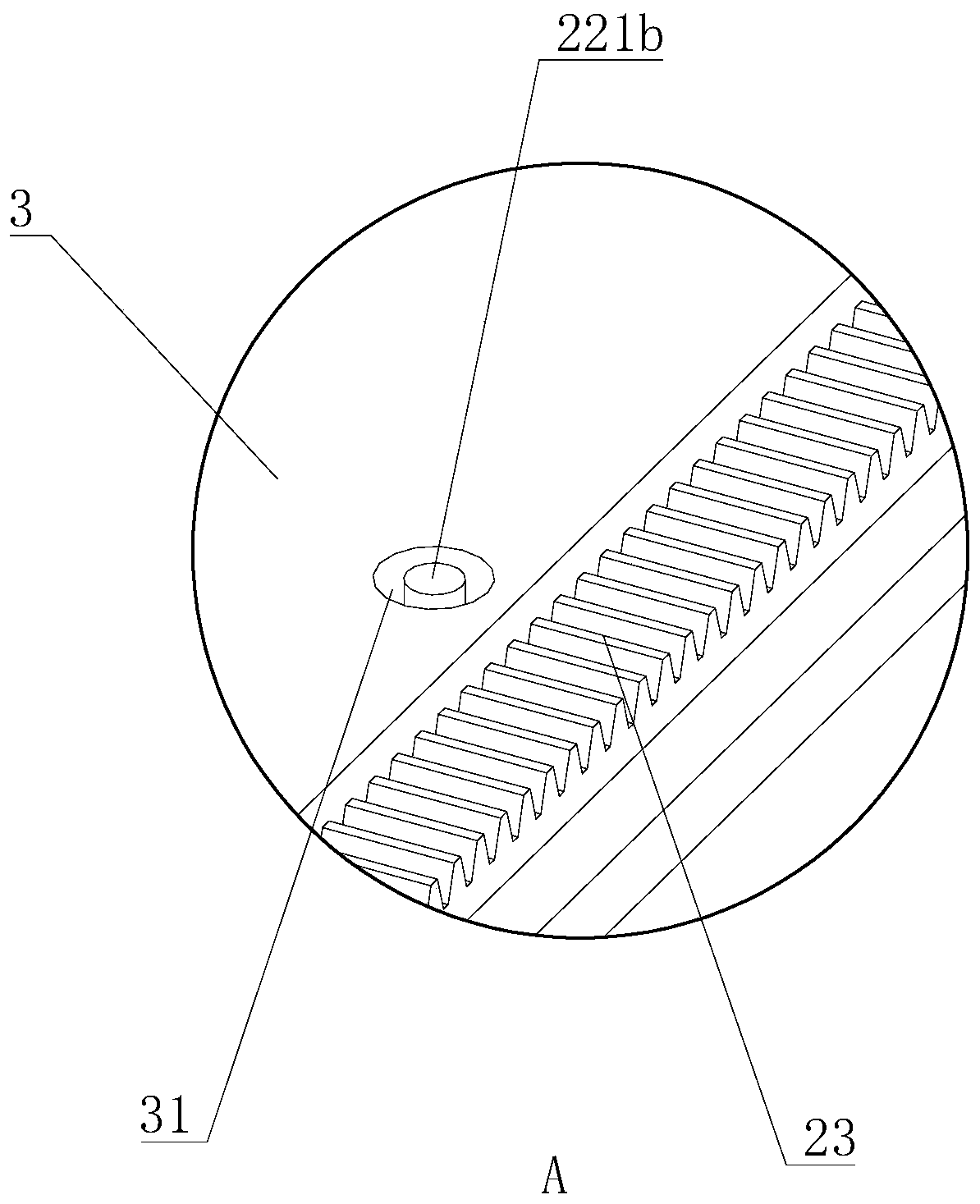

[0040] The furnace body 1 is also provided with a conveying mechanism 2 , a heat-resistant plate 3 placed on the conveying mechanism 2 , and a heat-resistant ash dish 4 placed on the heat-res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com