A method of niobium doping to increase the superconducting transition temperature of iron selenium

A technology of transition temperature and iron-selenium, which is applied in the field of niobium doping to increase the superconducting transition temperature of iron-selenium, can solve the problem that the superconducting performance is not significantly affected, and achieve the effect of increasing the superconducting transition temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

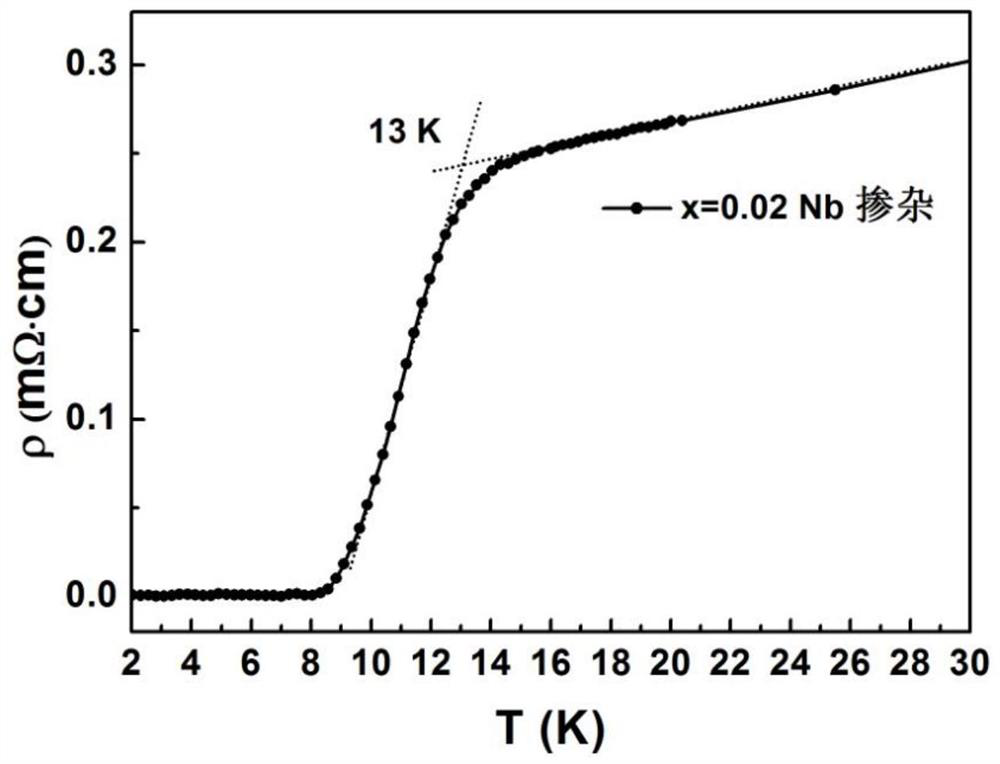

Embodiment 1

[0031] (1) take by weighing 3.006g iron powder and 3.952g selenium powder (the purity of iron powder and selenium powder is 99.5%, the atomic percent Fe of iron powder and selenium powder: Se=1:0.93), fully in agate mortar Grind for 20 minutes to get a uniform mixed powder. The weighing process and grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is pressed into tablets and vacuum-sealed into a quartz tube, and then placed in a tubular sintering furnace , Sintered at 600°C for 72h, and cooled to room temperature.

[0032] (2) Take out the sheet pre-sintered in the first step and place it in an agate mortar, fully grind it and add 0.1g of pure Nb powder (the purity of Nb powder is 99.5%, and the atomic percentage of Nb and FeSe is FeSe:Nb=1:0.02 ) and grind for another 30 minutes to mix well.

[0033] (3) The obtained mixed powder was compressed again and placed in a tube-type sintering furnace, vacuumed and filled with hig...

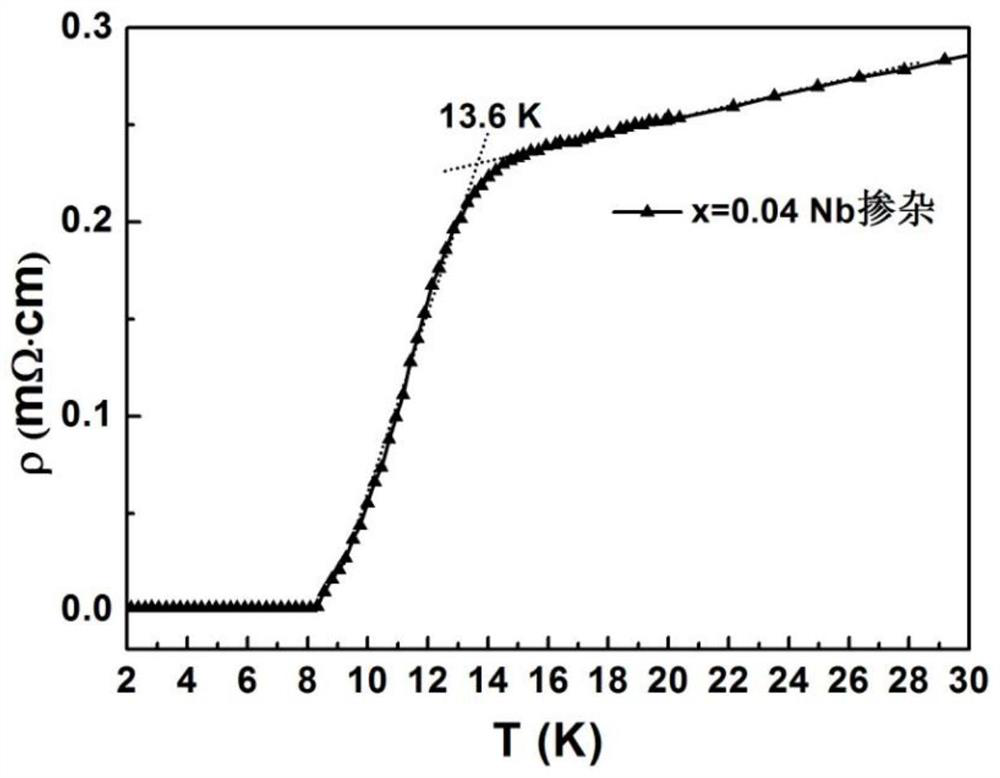

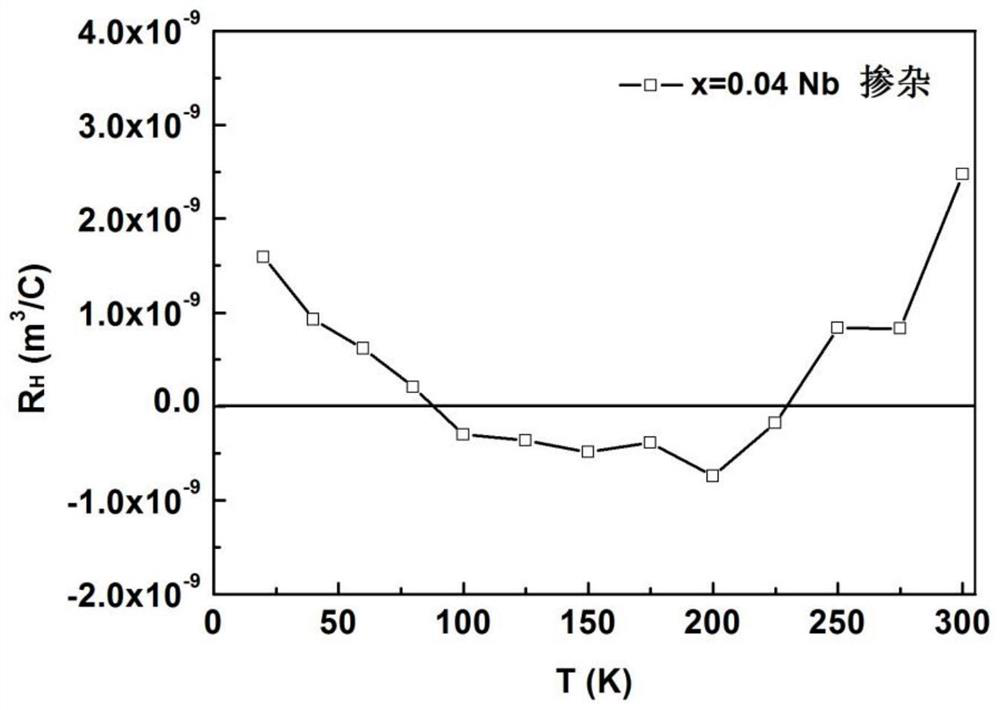

Embodiment 2

[0035] (1) take by weighing 1.503g iron powder and 2.018g selenium powder (the purity of iron powder and selenium powder is 99.5%, the atomic percentage Fe of iron powder and selenium powder: Se=1:0.95), fully in agate mortar Grind for 30 minutes to get a uniform mixed powder. The weighing process and grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is pressed into tablets and vacuum-sealed into a quartz tube, and then placed in a tubular sintering furnace , Sintered at 650°C for 72h, and cooled to room temperature.

[0036] (2) Take out the sheet pre-sintered in the first step and place it in an agate mortar, fully grind it and add 0.1g of pure Nb powder (the purity of Nb powder is 99.5%, and the atomic percentage of Nb and FeSe is FeSe:Nb=1:0.04 ), and grind for another 40 minutes to mix well.

[0037] (3) The obtained mixed powder was compressed again and placed in a tube-type sintering furnace, vacuumed and filled with...

Embodiment 3

[0039](1) take by weighing 1.202g iron powder and 1.615g selenium powder (the purity of iron powder and selenium powder is 99.5%, the atomic percentage Fe of iron powder and selenium powder: Se=1:0.95), fully in agate mortar Grind for 30 minutes to get a uniform mixed powder. The weighing process and grinding process are carried out in a glove box filled with high-purity argon; the ground mixed powder is pressed into tablets and vacuum-sealed into a quartz tube, and then placed in a tubular sintering furnace , Sintered at 650°C for 72h, and cooled to room temperature.

[0040] (2) Take out the sheet pre-sintered in the first step and place it in an agate mortar, fully grind it and add 0.1g of pure Nb powder (the purity of Nb powder is 99.5%, and the atomic percentage of Nb and FeSe is FeSe:Nb=1:0.05 ), and grind for another 40 minutes to mix well.

[0041] (3) The obtained mixed powder was compressed again and placed in a tube-type sintering furnace, vacuumed and filled with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com