Leg-type combined buffer for recoverable rocket landing mechanism

A buffer, leg-type technology, applied in the aerospace field, can solve the problems of low impact energy and inability to meet the rocket landing recovery, etc., to achieve stable impact force, good buffering energy absorption effect, and improving energy effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

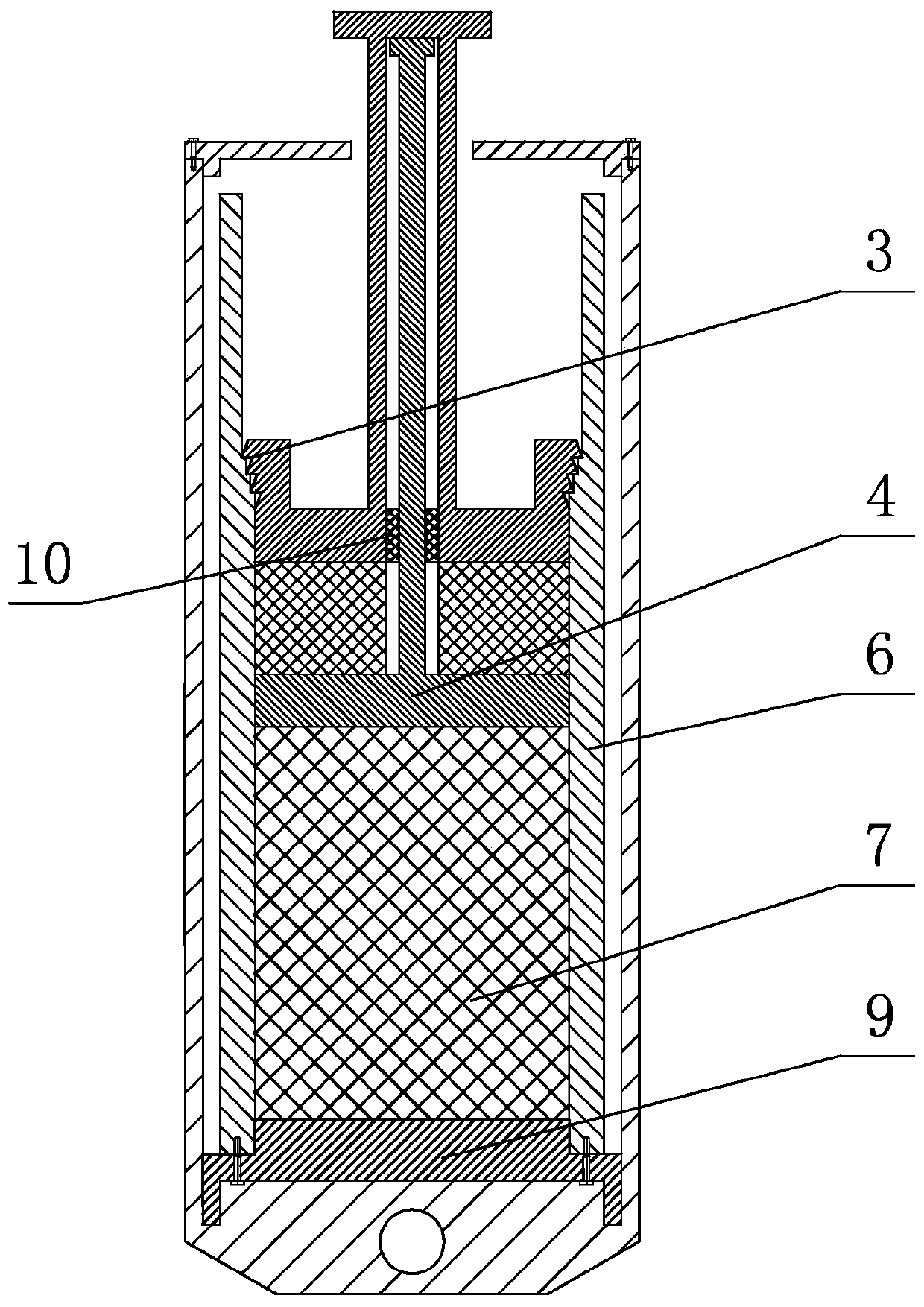

[0033] Specific implementation mode one: combine figure 1 , Figure 4 , Figure 6 and Figure 7 Describe this embodiment, a leg-type combined buffer for a recoverable rocket landing mechanism in this embodiment, it includes a buffer shell 8 and a buffer shell end cover 2, it also includes a first piston push rod 1, a broach 3. Second piston push rod 4, low-density metal honeycomb 5, buffer cavity 6, high-density metal honeycomb 7 and base 9,

[0034] The buffer housing 8 is a hollow cylinder structure, the buffer chamber 6 and the base 9 are sequentially arranged in the buffer housing 8 from top to bottom, the base 9 is fixed on the bottom of the buffer housing 8, and the buffer chamber 6 is fixed on the base 9 ,

[0035] The buffer cavity 6 is a hollow cylindrical structure, the first piston push rod 1, the low-density metal honeycomb 5, the second piston push rod 4 and the high-density metal honeycomb 7 are sequentially arranged in the buffer cavity 6 from top to bottom,...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination Figure 6 Describe this embodiment, the broach 3 of this embodiment has three rows of cutter teeth, respectively the first row of cutter teeth 3-1, the second row of cutter teeth 3-2 and the third row of cutter teeth 3-3, the first row of cutter teeth The outer diameters of the cutter teeth 3-1, the second row of cutter teeth 3-2 and the third row of cutter teeth 3-3 decrease successively from the cutting-in end to the cutting-out end. With such arrangement, when the broach 3 moves axially downward, each tooth will cut off a certain thickness of metal from the inner wall of the buffer cavity 6, thereby realizing cutting energy absorption. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination figure 1 The present embodiment will be described. The outer diameter of the broach 3 in this embodiment is smaller than the outer diameter of the buffer chamber 6 , and the inner diameter of the broach 3 is smaller than the inner diameter of the buffer chamber 6 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com