Medicine packaging box processing device

A processing device and packaging box technology, applied in the field of pharmaceutical packaging, can solve the problems of high cost, complex structure, low manufacturing and use costs, and achieve the effects of low manufacturing cost, avoiding cardboard damage, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

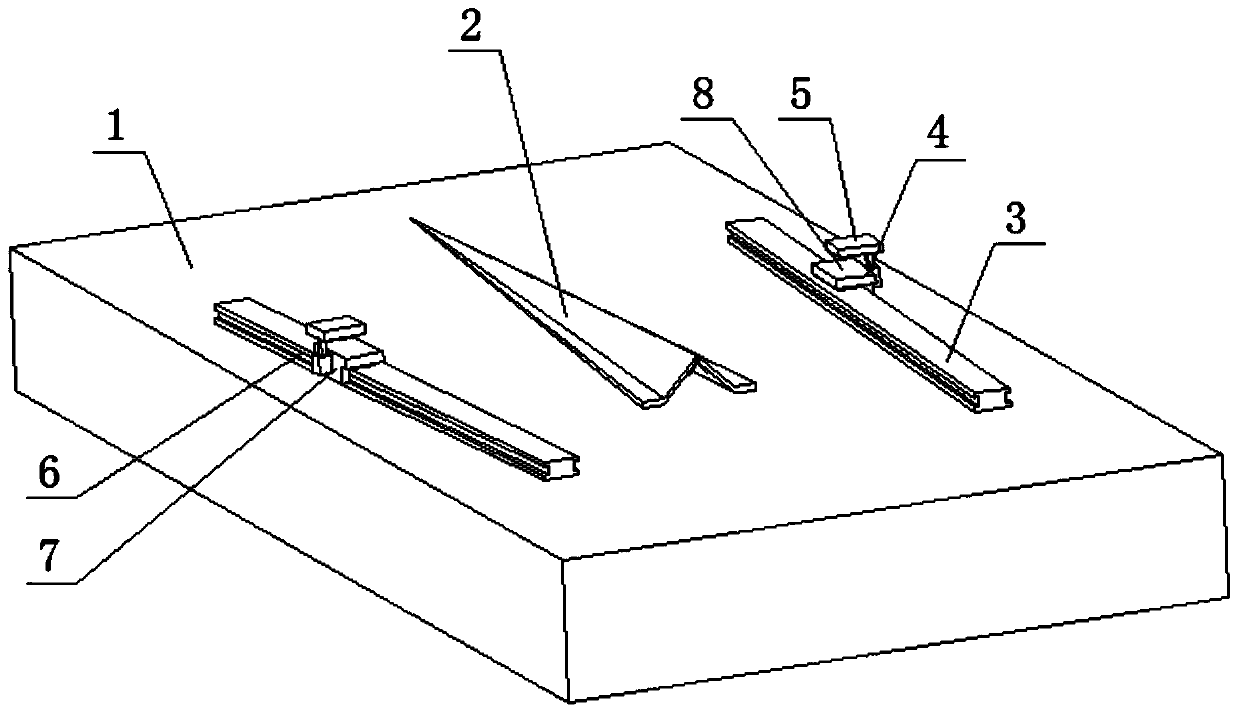

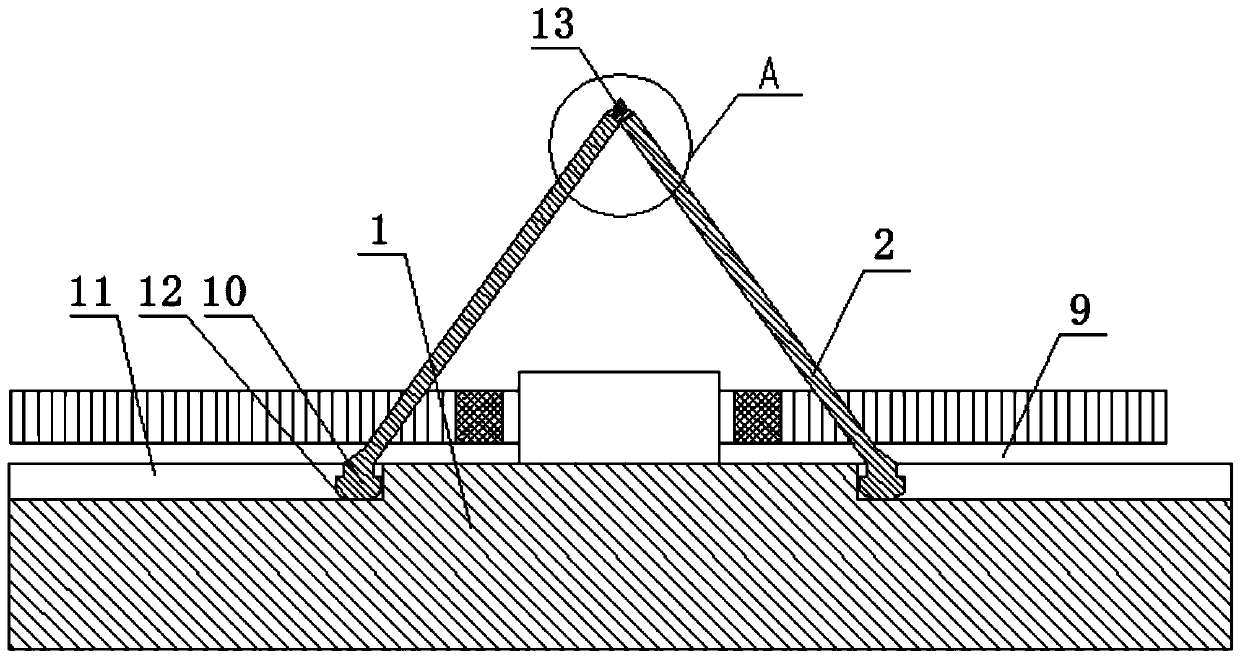

[0045] Such as Figure 1 to Figure 5 The medicine packaging box processing device shown includes a cardboard hemming device, and the cardboard hemming device includes a hemming workbench 1 and a hemming plate 2 installed on the hemming workbench 1, and the hemming plate 2 The upper end of the upper end is also provided with a straight top, and also includes a driving device for driving the cardboard to interact with the top, and the folding board 2 is two pieces, and the two folding boards 2 are in a plane-symmetrical relationship. And the symmetrical planes of the two flanging plates 2 are perpendicular to the table top of the flanging workbench 1;

[0046] The upper ends of the two flanging plates 2 are close to each other and are hingedly connected, and the upper ends of the two flanging plates 2 are parallel to each other;

[0047] It also includes a driving mechanism for adjusting the relative position of the lower ends of the two flanges 2, the driving mechanism include...

Embodiment 2

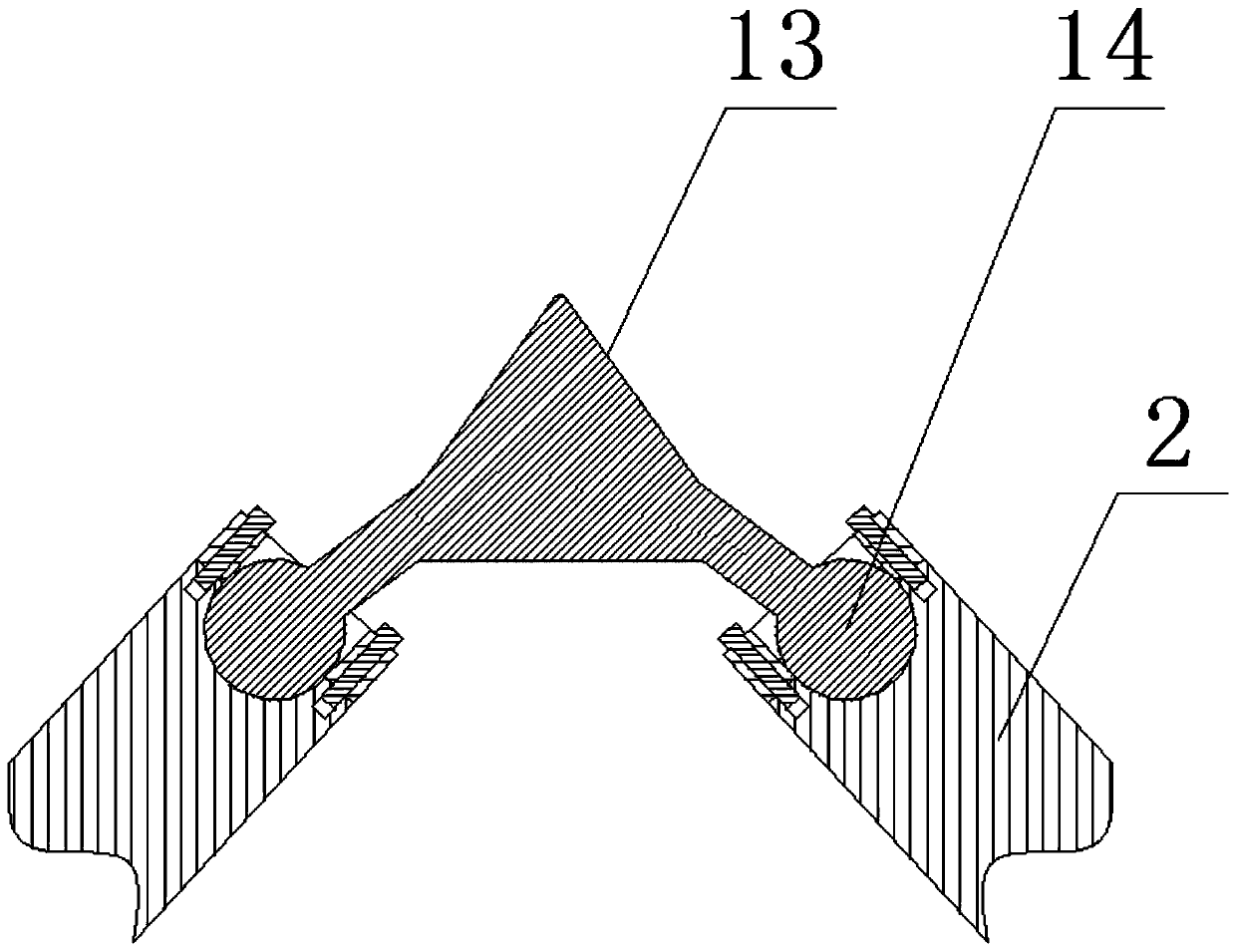

[0057] This embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 5As shown, in order to enable the top to maintain a stable projection position on the table to facilitate the quality of the hemming, it is set as follows: a strip-shaped hemming strip 13 is also included, the top is the top of the hemming strip 13, and the folding The left and right sides of the lower end of the edge strip 13 are all provided with hinged shafts 14, and the hinged shaft 14 on the left side of the hemmed strip 13 is hingedly connected with the upper end of the hemmed plate 2 on the left side of the hemmed strip 13, and the left side of the hemmed strip 13 is hingedly connected. The hinged shaft 14 is hingedly connected to the upper end of the flanged board 2 on the right side of the flanged strip 13, and the hinged shaft 14 is parallel to the upper end of any flanged board 2. The above hinge shafts 14 cooperate with the helical direction of the thread on the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com