Injection mold convenient to use

A convenient technology for injection molds, applied in the field of injection molds, can solve the problems of increasing the cooling time of injection molds, condensation, etc., to achieve the effects of preventing condensation, reducing cooling time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

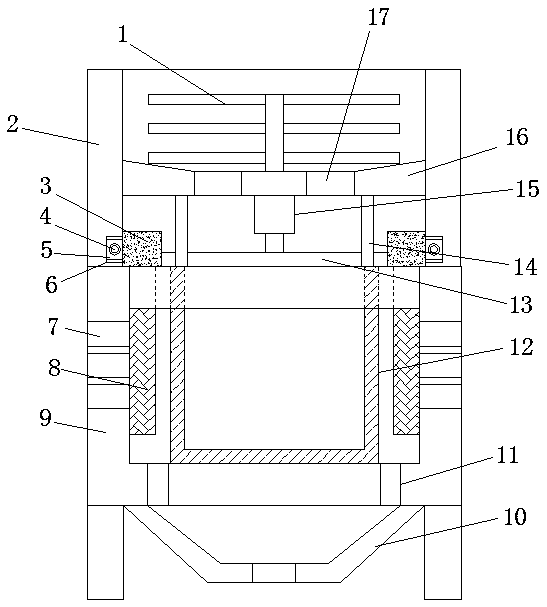

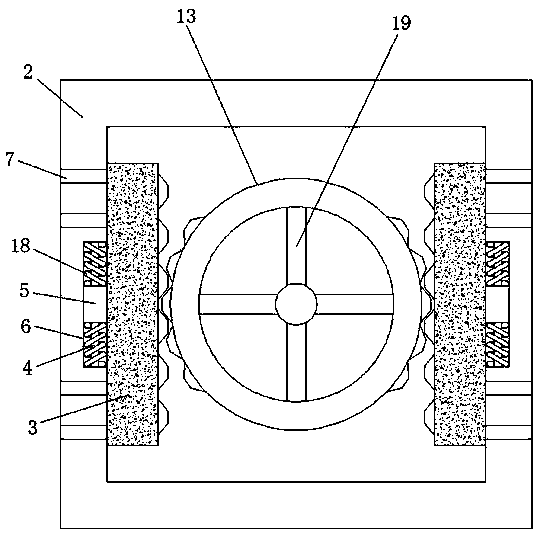

[0018] Embodiment: When in use, first place the material tank 2 on the cooling tank 9, then pour the injection molding material into the material tank 2, start the biaxial motor 15, and the output shaft of the biaxial motor 15 drives the two rotating rods to rotate , the rotating rod located above drives the stirring rod 1 to rotate, and the stirring rod 1 stirs the raw materials in the storage tank 2, and the stirred raw materials enter the injection mold body 12 in the cooling tank 9 through the lower liquid hole 17, and At the same time, the rotating rod positioned below will drive the connecting rod 19 and the gear plate 13 to rotate, the gear plate 13 will drive the movable plate 3 to move, and the movable plate 3 will drive the slider 5 to slide in the chute 6. 4, the slider 5 will also squeeze the spring 18. When the movable plate 3 moves, the movable plate 3 drives the baffle 8 to move, so that the circular through hole on the baffle 8 coincides with the injection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com