Machining device

A technology for machining and processing parts, applied in the field of abrasive tool processing equipment, can solve the problems of slow processing and forming of mold processing equipment, insufficient protection of processing personnel, expensive equipment, etc., and achieve fast processing and forming, good protection, and universal processing high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

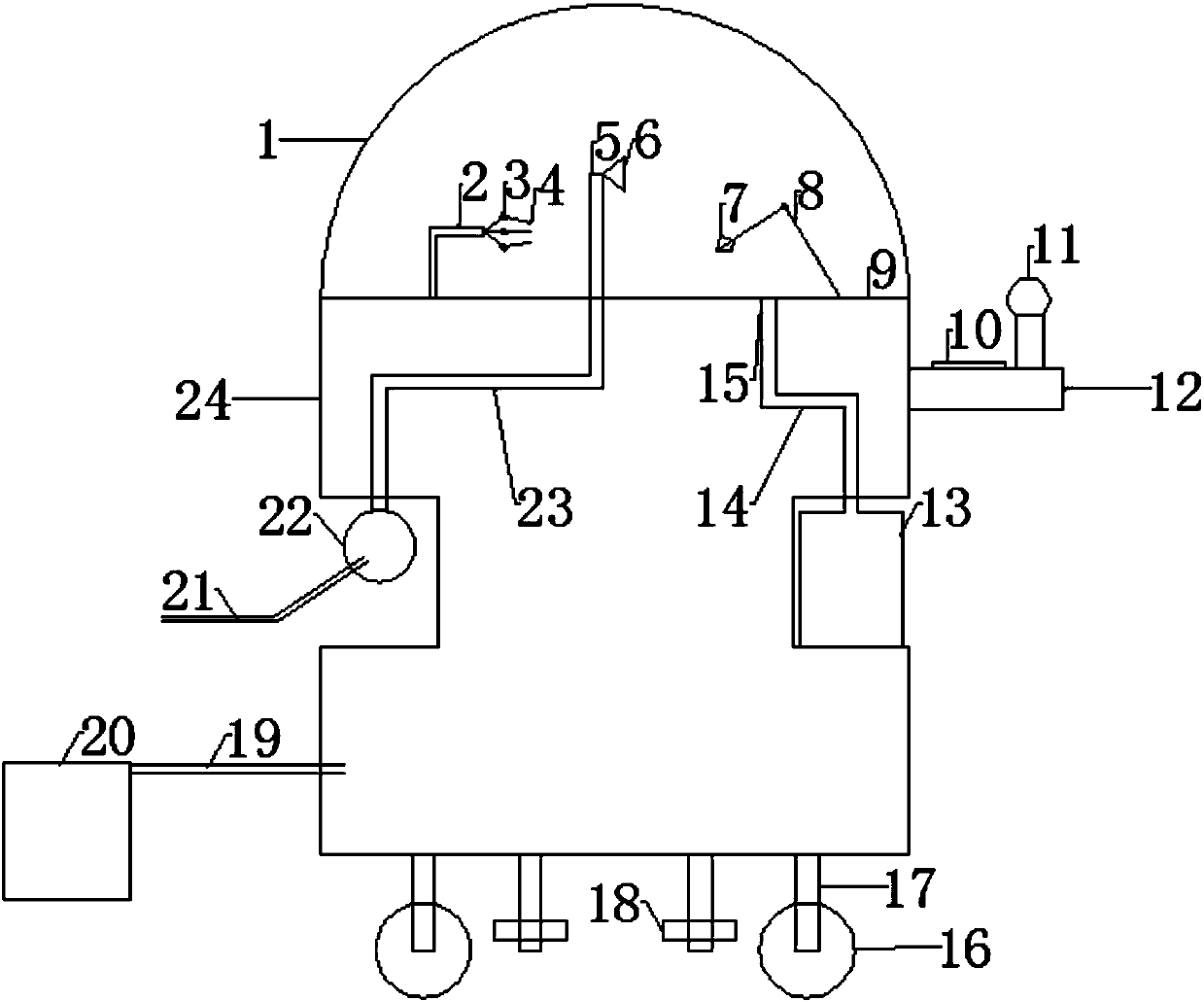

[0032] Cancel the restriction of the fixing device 18, move the machined device to a suitable position through the wheel 16, and use the fixing device 18 to fix it, turn on the drive device 20 to supply energy, fix the workpiece to be processed on the jaw 4, and turn on the water pump 22. The nozzle 6 starts to spray cooling water, and the first processing mechanism and the second processing mechanism are controlled by the button 10 and the operating lever 11 to perform processing. After the operation is completed, the driving device 20 is turned off, and the waste liquid in the water tank is drained to complete Processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com