Four-point multi-link pressing machine adopting double-servo drive

A four-point type press technology, applied in the field of forging machinery, can solve the problems of servo motor synchronous control error, reduce the effective output capacity of servo press, and the difficulty of servo motor to meet high power and high torque, etc., to achieve high-efficiency mechanical gain, Effects of reducing power, stabilizing pressure relief and pressure holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

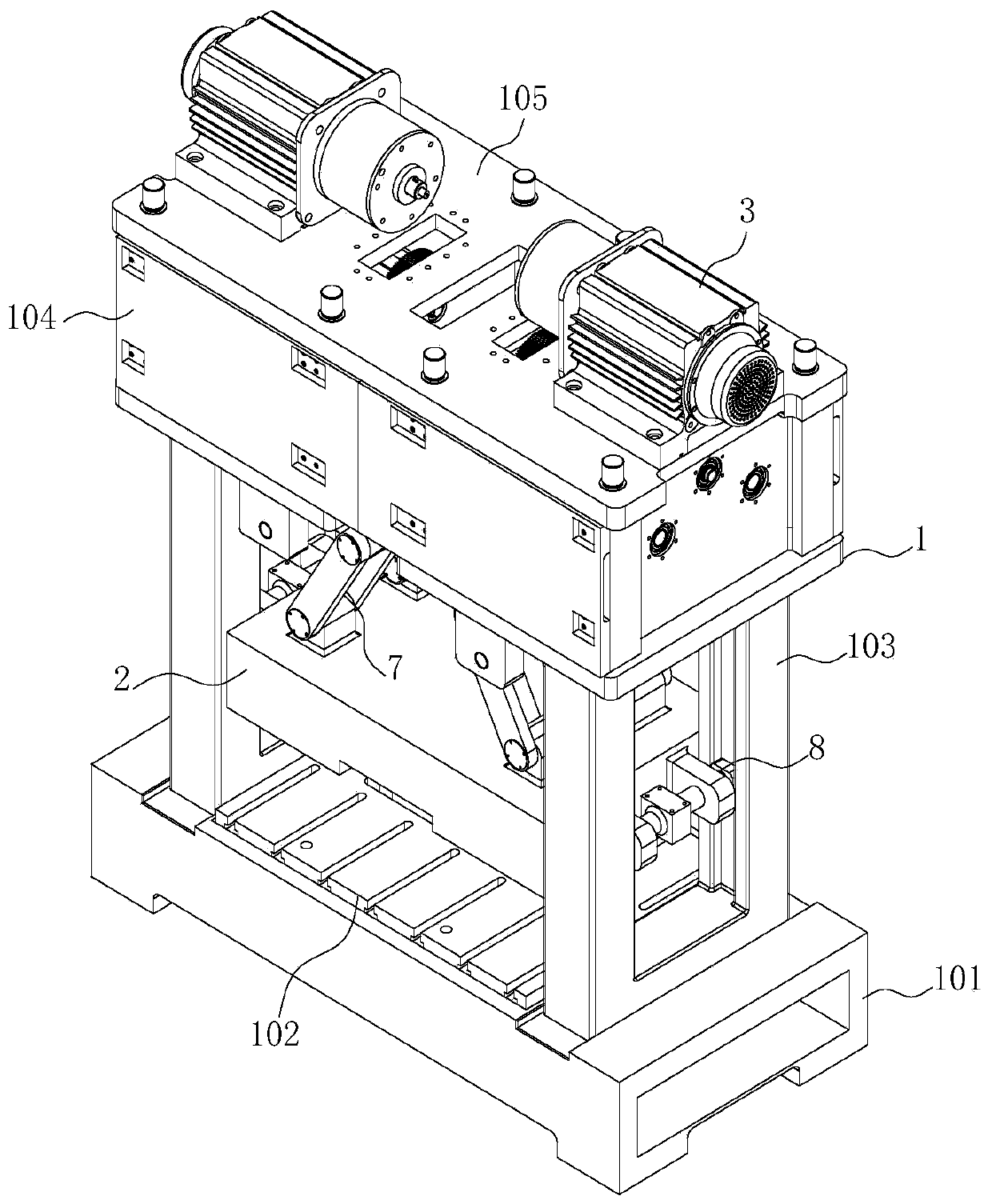

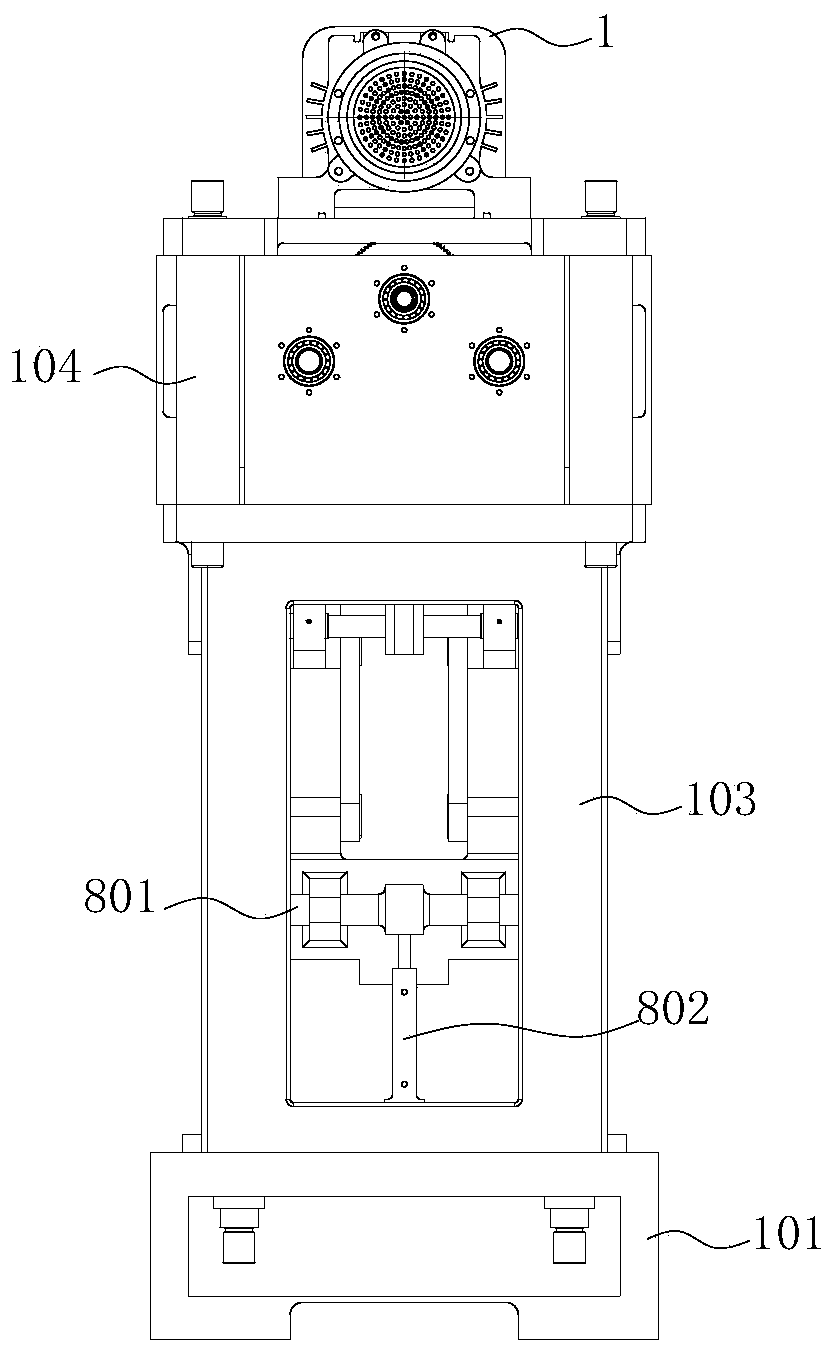

[0051] See attached figure 1 - attached Figure 4 , a kind of double servo drive four-point multi-linkage press of the present invention comprises:

[0052] Fuselage 1, said fuselage 1 comprises a base 101, a workbench 102 fixed on the upper surface of the base 101, a bracket 103 supported on the upper surface of the base 101, a transmission box 104 fixed on the upper end of the bracket 103, and a set A machine cover 105 at the upper end of the transmission box body 104;

[0053] The downward slider 2 that slides up and down relative to the support 103 inside the fuselage 1;

[0054] The planetary gear reduction device 3 fixed on the upper end of the cover 105;

[0055] Auxiliary reduction unit 4 connected with planetary gear reduction device 3;

[0056] A power input unit 5 connected to the auxiliary deceleration unit 4, the power input unit 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com