Processing technology of minced fruits

A processing technology and fruit technology, applied in the field of fruit puree, can solve the problems of reducing the storage time, difficult to absorb by the human body, and difficult to kill bacteria, and achieve the effects of avoiding the deterioration of nutrients, improving nutritional value, and improving storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

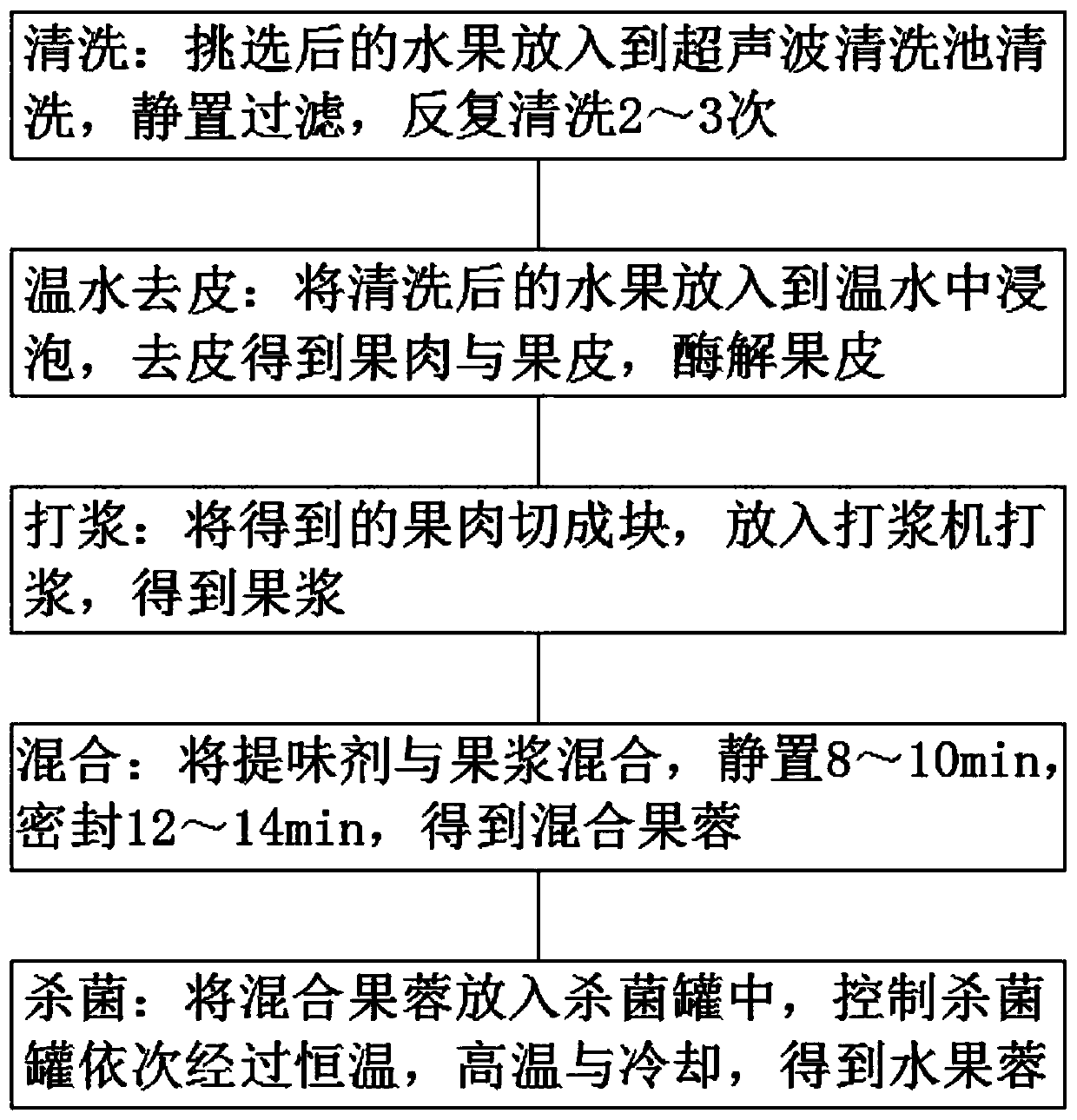

[0028] Such as figure 1 shown, including the following steps:

[0029] (1), Cleaning: Put the selected fruit into an ultrasonic cleaning tank for cleaning, in parts by weight: add 60 parts of flour, 23 parts of edible salt and 13 parts of NaHCO to 1000 parts of water 3 , standing and filtering, when filtering, use a 150-mesh stainless steel filter to filter, and wash it twice;

[0030] (2) Peeling in warm water: soak the cleaned fruit in warm water at a temperature of 40°C. When soaking, use a sieve plate to squeeze the fruit into the water for 12 minutes. Peel the fruit to obtain the pulp and peel , enzymatically hydrolyzing the pericarp to obtain a flavor enhancer, the enzymatically hydrolyzing the pericarp comprises the following steps:

[0031] (2.1), put the pericarp into a grinder and grind it, then add cellulase to mix, leave it alone to obtain the enzymatic hydrolyzed pericarp, in parts by weight, add 1.5 parts of cellulase in every 100 parts of pericarp, the standin...

Embodiment 2

[0037] Such as figure 1 shown, including the following steps:

[0038] (1), Cleaning: Put the selected fruit into an ultrasonic cleaning tank for cleaning, in parts by weight: add 60 parts of flour, 23 parts of edible salt and 13 parts of NaHCO to 1000 parts of water 3 , standing and filtering, when filtering, use a 150-mesh stainless steel filter to filter, and wash it twice;

[0039] (2) Peeling in warm water: soak the cleaned fruit in warm water at a temperature of 40°C. When soaking, use a sieve plate to squeeze the fruit into the water for 12 minutes. Peel the fruit to obtain the pulp and peel , enzymatically hydrolyzing the pericarp to obtain a flavor enhancer, the enzymatically hydrolyzing the pericarp comprises the following steps:

[0040] (2.1), put the pericarp into a grinder and grind it, then add cellulase to mix, leave it alone to obtain the enzymatic hydrolyzed pericarp, in parts by weight, add 1.5 parts of cellulase in every 100 parts of pericarp, the standin...

Embodiment 3

[0046] Such as figure 1 shown, including the following steps:

[0047] (1), Cleaning: Put the selected fruit into an ultrasonic cleaning tank for cleaning, in parts by weight: add 60 parts of flour, 23 parts of edible salt and 13 parts of NaHCO to 1000 parts of water 3 , static filtration, filtration: use 150-mesh stainless steel filter to filter, and wash repeatedly 2 times;

[0048] (2), warm water peeling: put the cleaned fruit into warm water for soaking, the temperature of warm water is 40°C, soaking: use a sieve plate to squeeze the fruit into the water, soaking time is 12min, peel to get pulp and peel, Enzymatically hydrolyzing the pericarp to obtain a flavor enhancer, the enzymatically hydrolyzing the pericarp comprises the following steps:

[0049] (2.1), put the pericarp into a grinder and grind it, then add cellulase to mix, leave it alone to obtain the enzymatic hydrolyzed pericarp, in parts by weight, add 1.5 parts of cellulase in every 100 parts of pericarp, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com