Sealing system of radiation chamber furnace tube of tube-type heating furnace

A tubular heating furnace and sealing system technology, which is applied to electric furnace heating, lighting and heating equipment, furnaces, etc., can solve the problems of occupying maintenance space, complicated construction procedures, and difficult to find furnace tube problems, so as to avoid through seams and seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

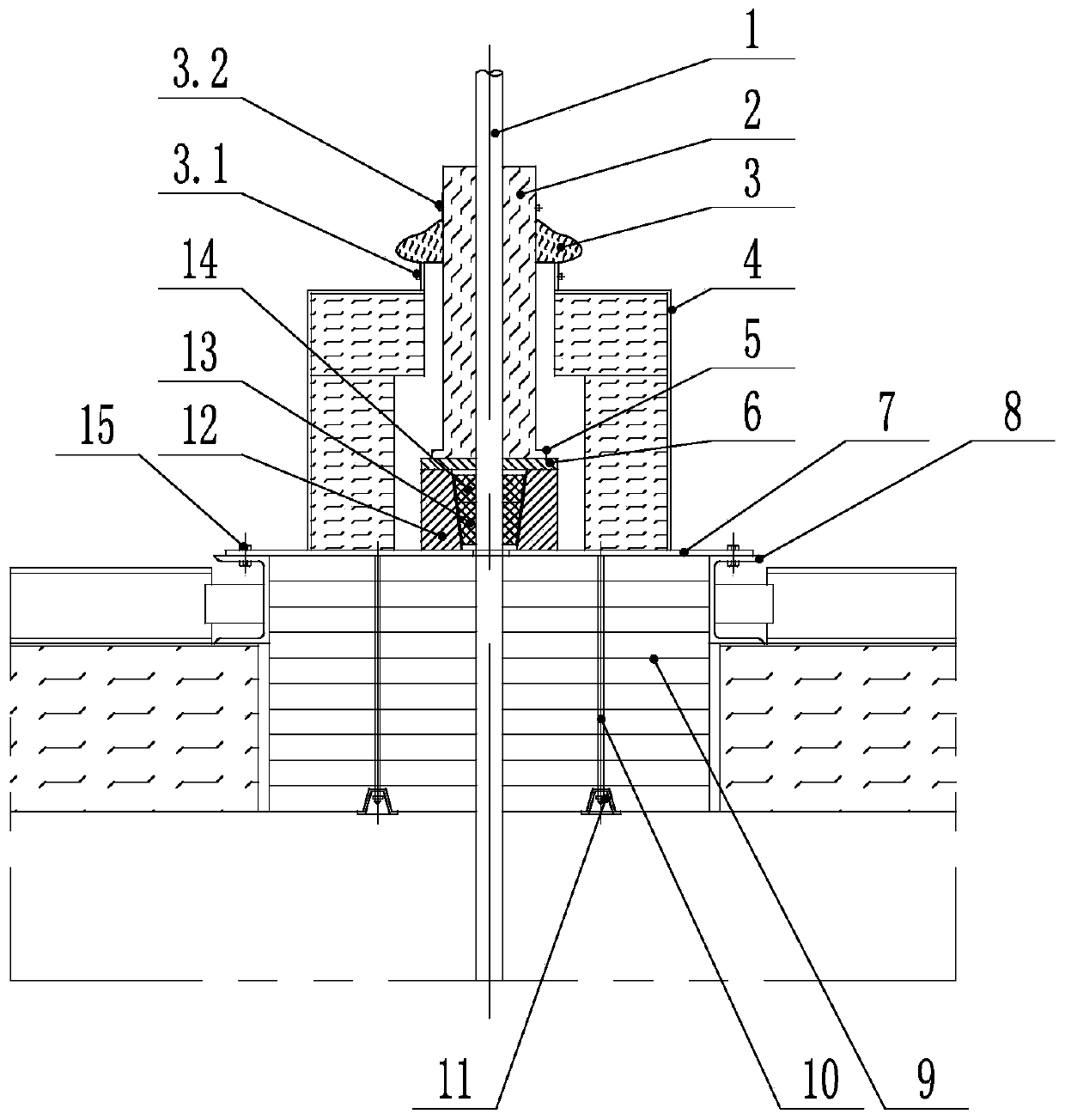

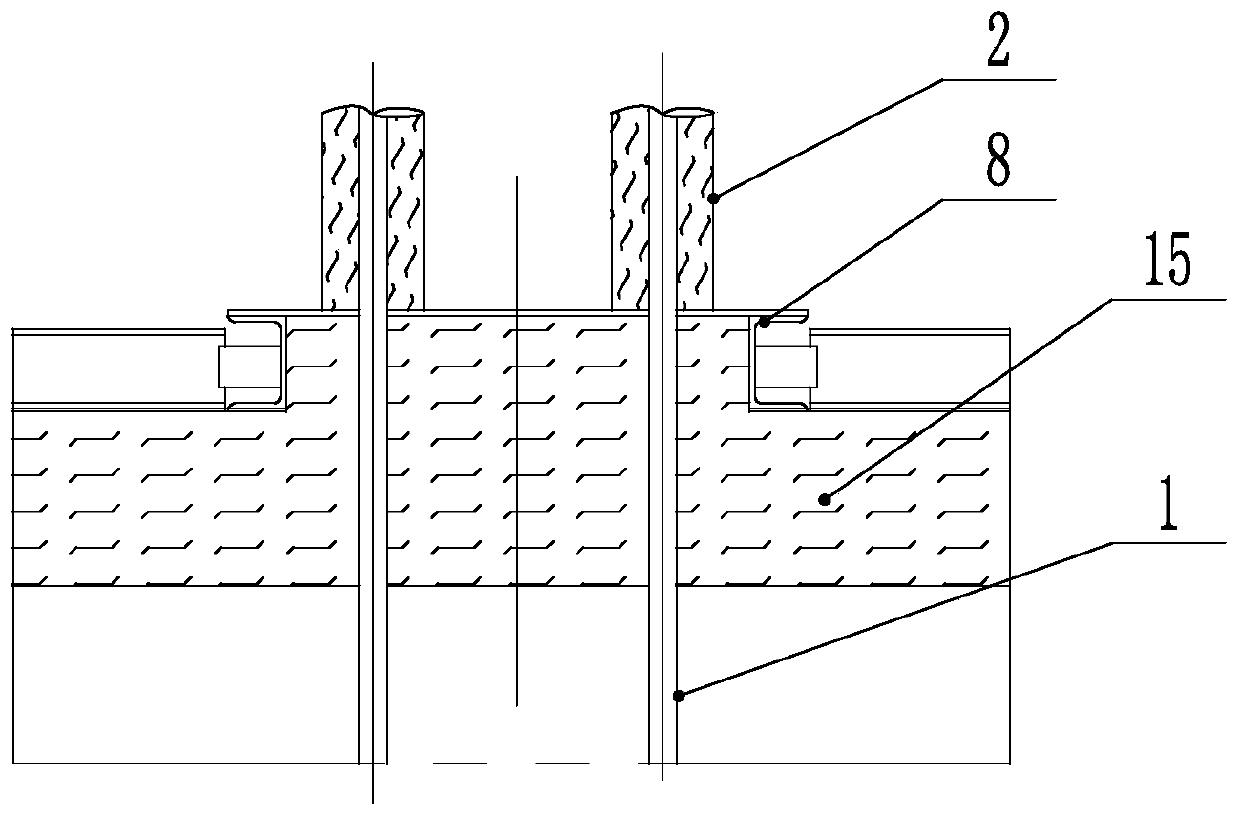

[0098] Such as figure 2 As shown, the furnace tube sealing system of the radiant chamber of the tube heating furnace according to the present invention includes a furnace roof slide plate 7 arranged around the furnace tube 1. The seal arranged on the tube 1, the heat preservation sleeve 2 is arranged around the furnace tube 1 above the seal, the seal and the heat preservation sleeve 2 are provided with a seal box 4, and the heat preservation sleeve 2 protrudes from the seal box 4 to be set; the seal box 4 and There is a margin of activity between the insulation sleeve 2, and a margin of activity between the sealing box 4 and the sealing member;

[0099] The seal includes a seal base 12, the bottom of the seal base 12 is slidably connected to the top slide plate 7, and the seal base 12 runs through the seal base 12 longitudinally to provide a tapered hole, and the tapered hole is provided with a tapered seal. The conical seal is set in cooperation with the conical hole, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com