Lamp demisting structure and motor vehicle illuminating equipment with structure

A lamp and anti-fog technology, which is applied in lighting and heating equipment, motor vehicles, road vehicles, etc., can solve the problems of limited service life of the anti-fog layer, loss of defogging effect, and affecting the use effect of lamps, and achieve the goal of improving the moisture absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein like reference numerals designate like or similar elements throughout. The specific embodiments described below with reference to the accompanying drawings are exemplary and intended to explain the present invention, but not construed as a limitation of the present invention.

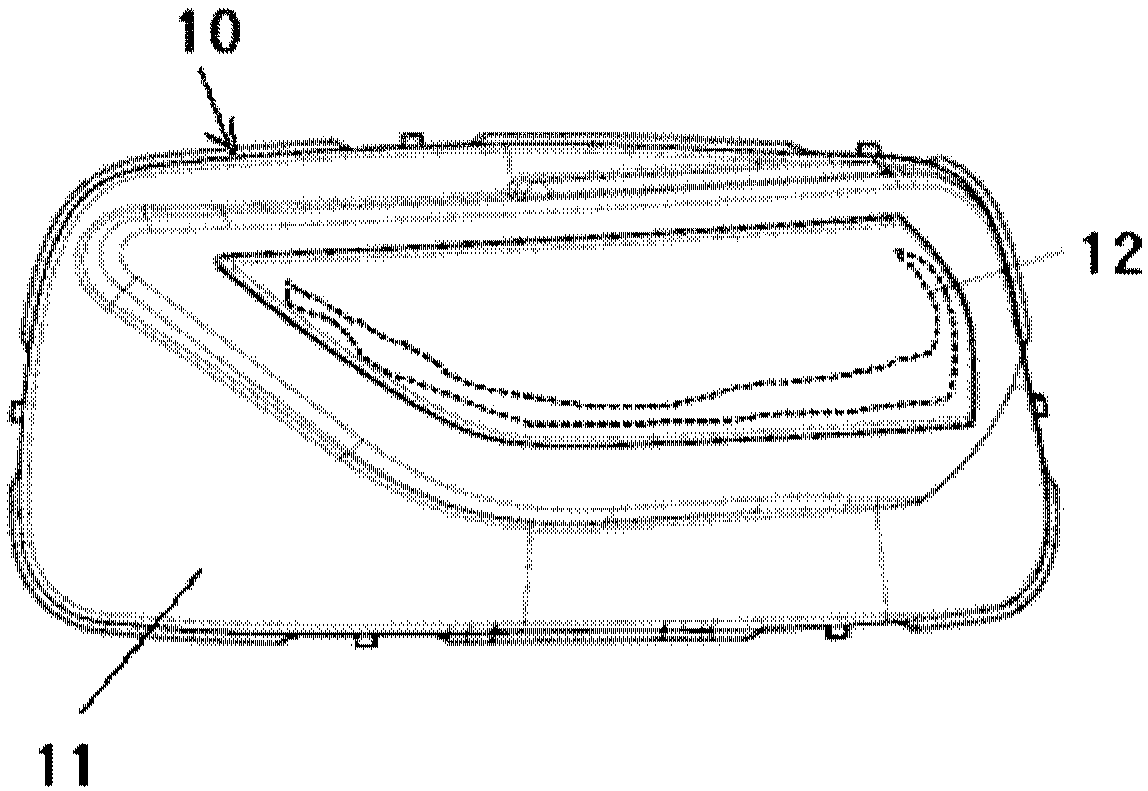

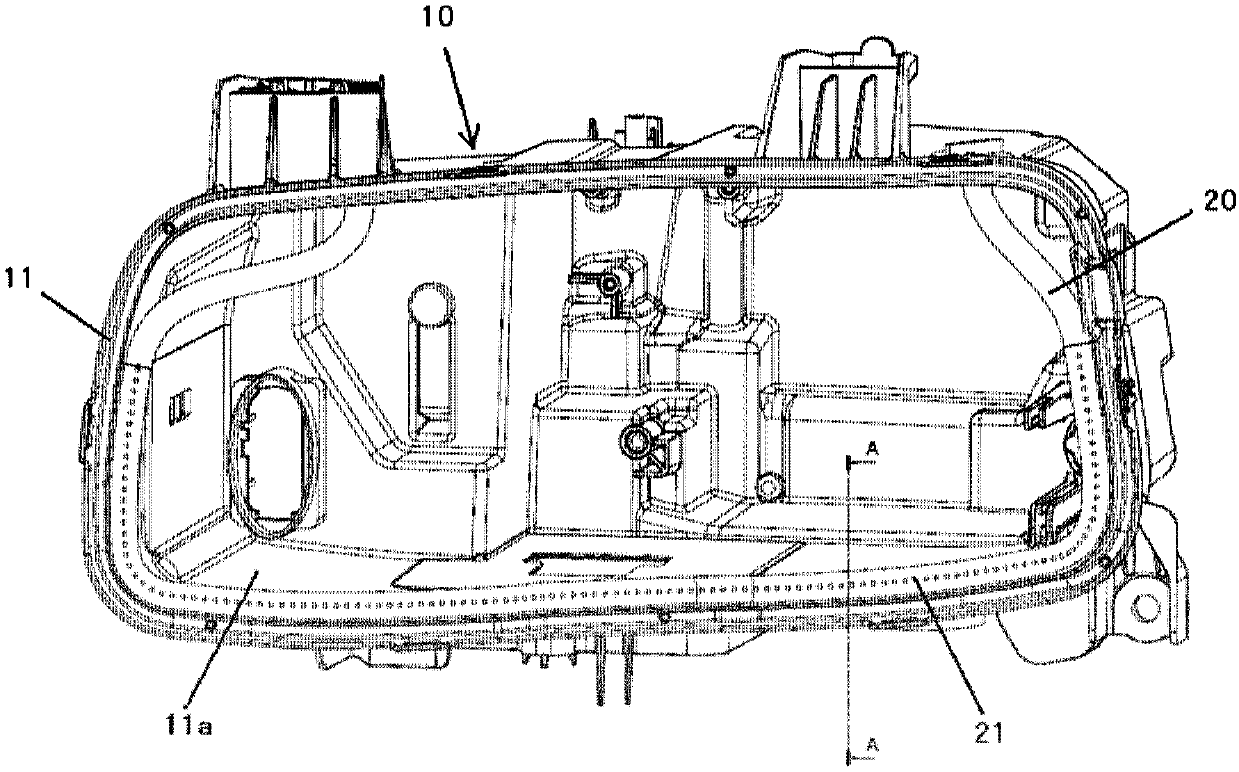

[0038] In order to clearly describe and introduce the inventive concept of the present invention, the motor vehicle headlamp will be adopted as an example below in conjunction with the attached Figure 1-6 Specific examples of the present invention are described. In the attached picture, figure 1 It is a structural schematic diagram of a lighting device for a motor vehicle (for example, a headlight) according to an embodiment of the present invention, where the dotted line part schematically shows the fog condensation area 12 in the lamp; figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com