Pneumatic anchor net continuous-buckling machine for double-ring forming

A technology of continuous buckle and anchor net, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of cumbersome work, loose knots, high labor intensity, etc., and achieves improved safety performance, easy to carry and move, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

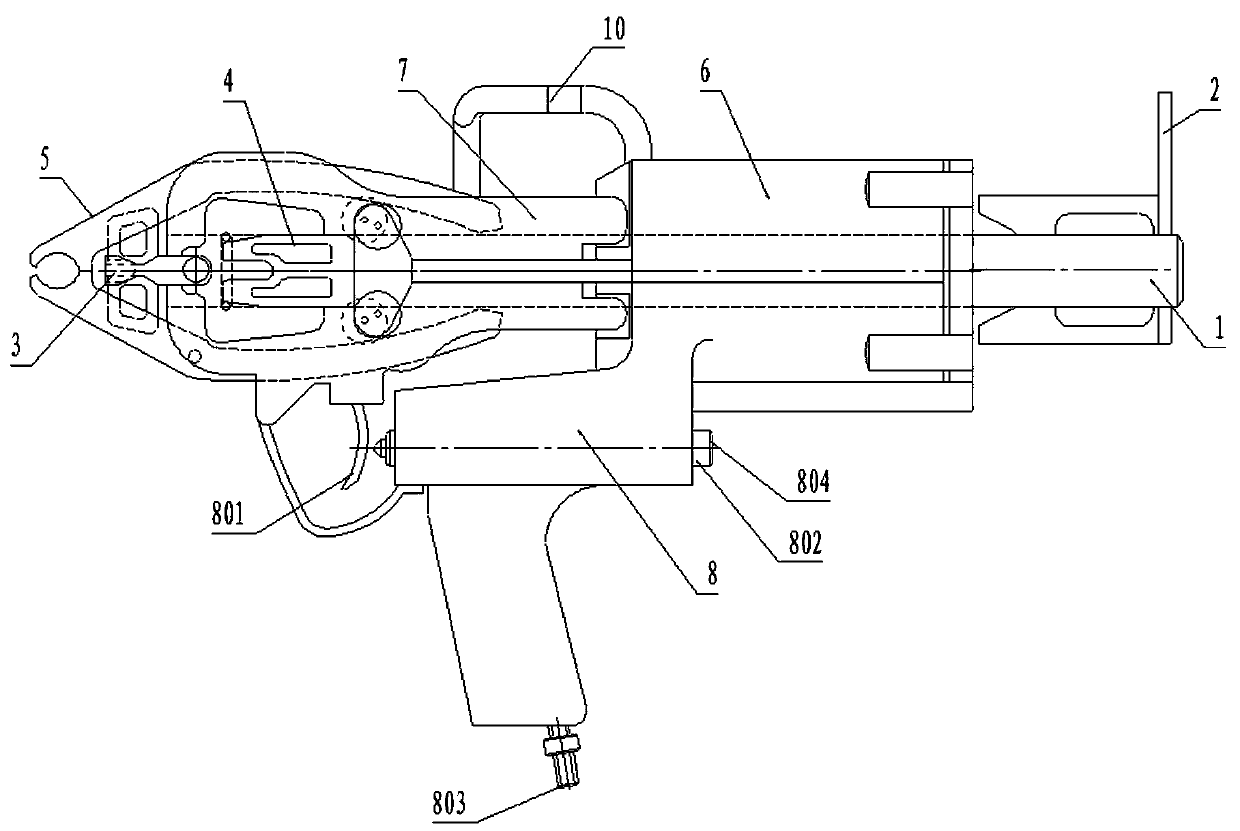

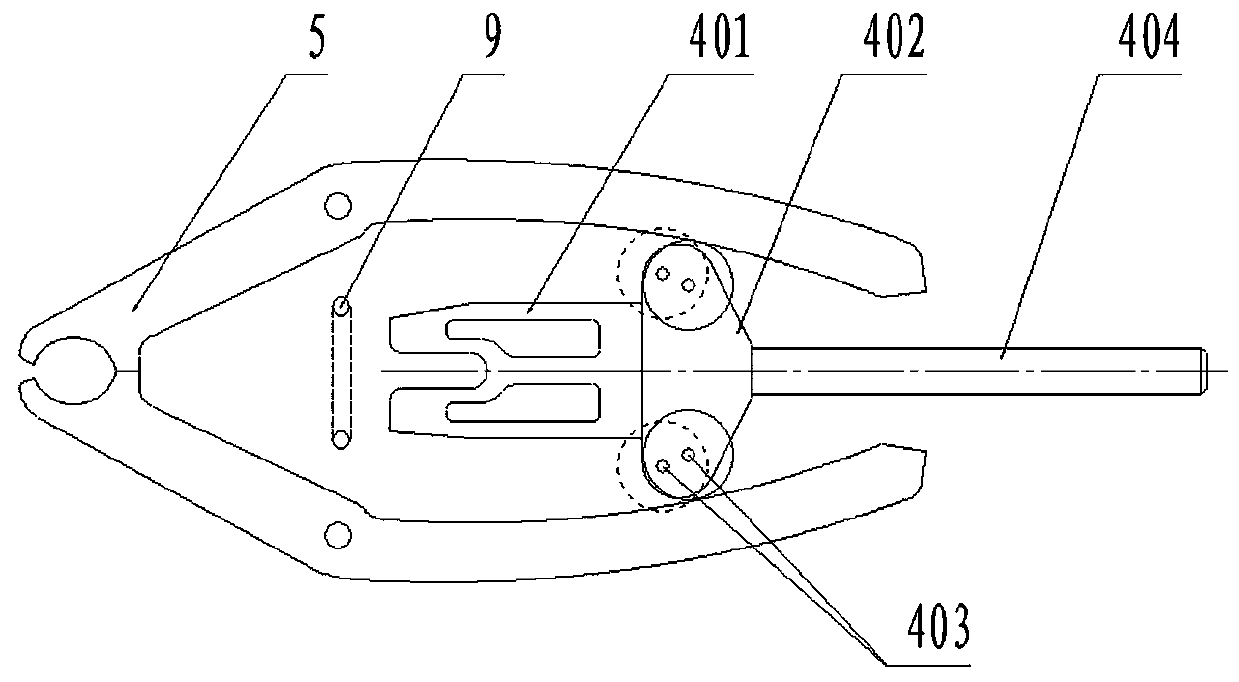

[0027] Such as Figure 1-Figure 11 It can be seen that a double-loop forming pneumatic anchor net fastening machine in this embodiment includes a nail feeding guide rail 1, a nail feeder 2, a nail backstop 3, a push nail assembly 4, a forming clamp 5, a cylinder 6, a whole Machine support 7, pneumatic control assembly 8 and the button nail 9 that movable cover is sent on the nail guide rail 1. A kind of double-circle forming pneumatic anchor net connecting button machine of this embodiment is to fasten the button nail 9 into two circles. The button nail 9 is made of zinc-aluminum alloy material, and the button has high tensile strength and is not easy to rust; Formed twice, the knot is firm, the tensile strength is high, and it can bear the pressure of the top plate.

[0028] The nail feeding guide rail 1 of the present embodiment is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com