Composite floor for floor heating and mounting method of composite floor

A composite floor, floor heating technology, applied in the application, heating method, home appliances and other directions, can solve the problem of high cost, and achieve the effect of reducing labor costs, reducing steps, and avoiding uneven ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

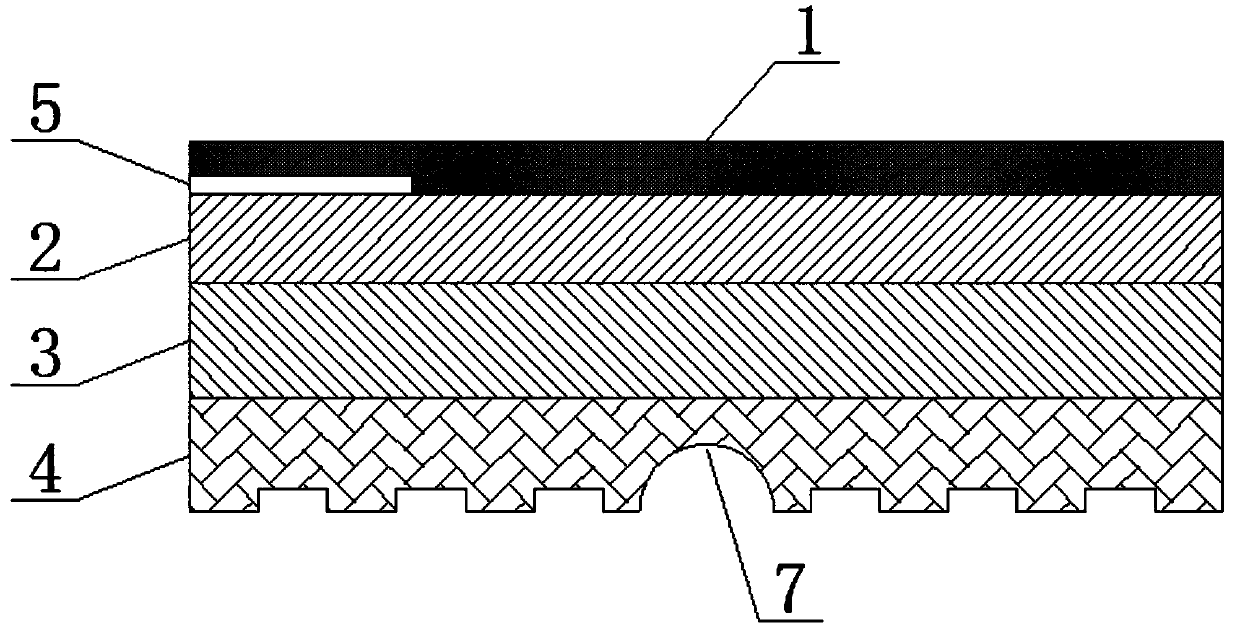

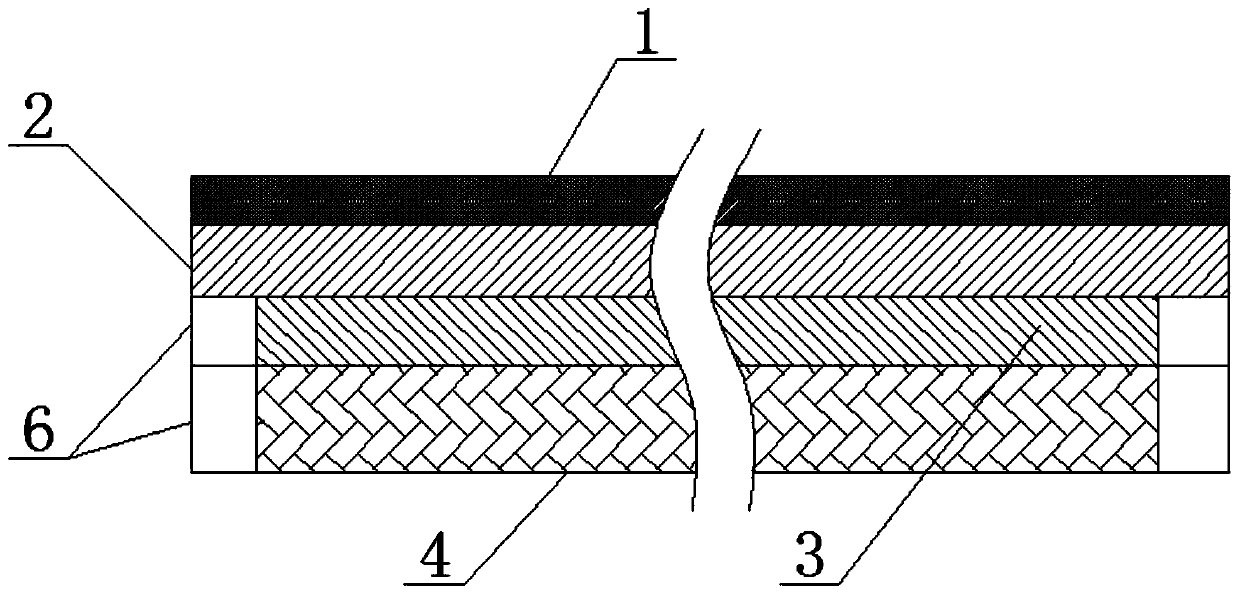

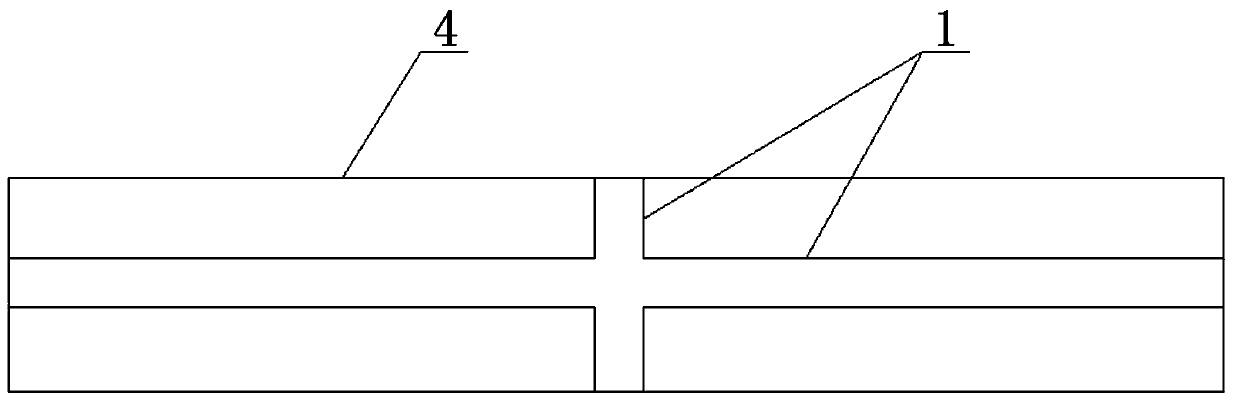

[0046] Such as figure 1A composite floor for floor heating shown includes a protective layer 1, a heating layer 2, an insulating layer 3 and a base layer 4; the protective layer 1 is a plastic coating with a thickness of 1.5 mm coated on the surface of the heating layer 2, and the heating layer 2 is Plate-shaped electric heating heating device, the lower side of the heating layer 2 is bonded with an insulating layer 3, and a base layer 4 is arranged under the insulating layer 3, and the base layer 4 is a keel. The composite floor for floor heating also includes a temperature measuring head 5 and temperature control equipment. The temperature head 5 is closely connected with the heating layer 2, such as figure 2 As shown, the ends of the insulation layer 3 and the base layer 4 have grooves 6 for wiring, such as image 3 As shown, the bottom of the base layer 4 is provided with a wire slot 7, and the wire slot 7 is two straight slots interlaced to form a cross.

[0047] The p...

Embodiment 2

[0064] Such as Figure 4 A composite floor for floor heating shown includes a protective layer 1, a heating layer 2, an insulating layer 3 and a base layer 4; the protective layer 1 is a plastic coating with a thickness of 1.5 mm coated on the surface of the heating layer 2, and the heating layer 2 is Plate-shaped electric heating heating device, the lower side of the heating layer 2 is bonded with an insulating layer 3, and a hollow channel 8 is arranged in the insulating layer 3. The cross section of the channel 8 is rectangular, and a base layer 4 is arranged under the insulating layer 3, and the base layer 4 is a keel. The composite floor for floor heating also includes a temperature measuring head 5 and temperature control equipment, and the temperature measuring head 5 is closely connected with the heating layer 2, such as figure 2 As shown, the ends of the insulation layer 3 and the base layer 4 have grooves 6 for wiring, such as image 3 As shown, the bottom of the b...

Embodiment 3

[0082] Such as Figure 5 A composite floor for floor heating shown includes a protective layer 1, a heating layer 2, an insulating layer 3 and a base layer 4; the protective layer 1 is a plastic coating with a thickness of 1.5 mm coated on the surface of the heating layer 2, and the heating layer 2 is A plate-shaped electric heating heating device, the lower side of the heating layer 2 is bonded with an insulating layer 3, and a hollow channel 8 is arranged in the insulating layer 3. The cross section of the channel 8 is circular, and the channel 8 is filled with insulating foam 9. A base layer 4 is arranged under the insulation layer 3, and the base layer 4 is a keel. The composite floor for floor heating also includes a temperature measuring head 5 and a temperature control device. The temperature measuring head 5 is closely connected with the heating layer 2, such as figure 2 As shown, the ends of the insulation layer 3 and the base layer 4 have grooves 6 for wiring, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com