Fabric humidifier for spinning machinery

A technology of textile machinery and humidifier, which is applied to the processing of textile material drums, equipment configuration for processing textile materials, spraying/spraying of textile materials, etc. It can solve the problems of inconvenient ironing, large manpower consumption, and uniform moisture, and achieve overall The structural design is compact and reasonable, reducing the loss of energy consumption and the effect of reducing mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

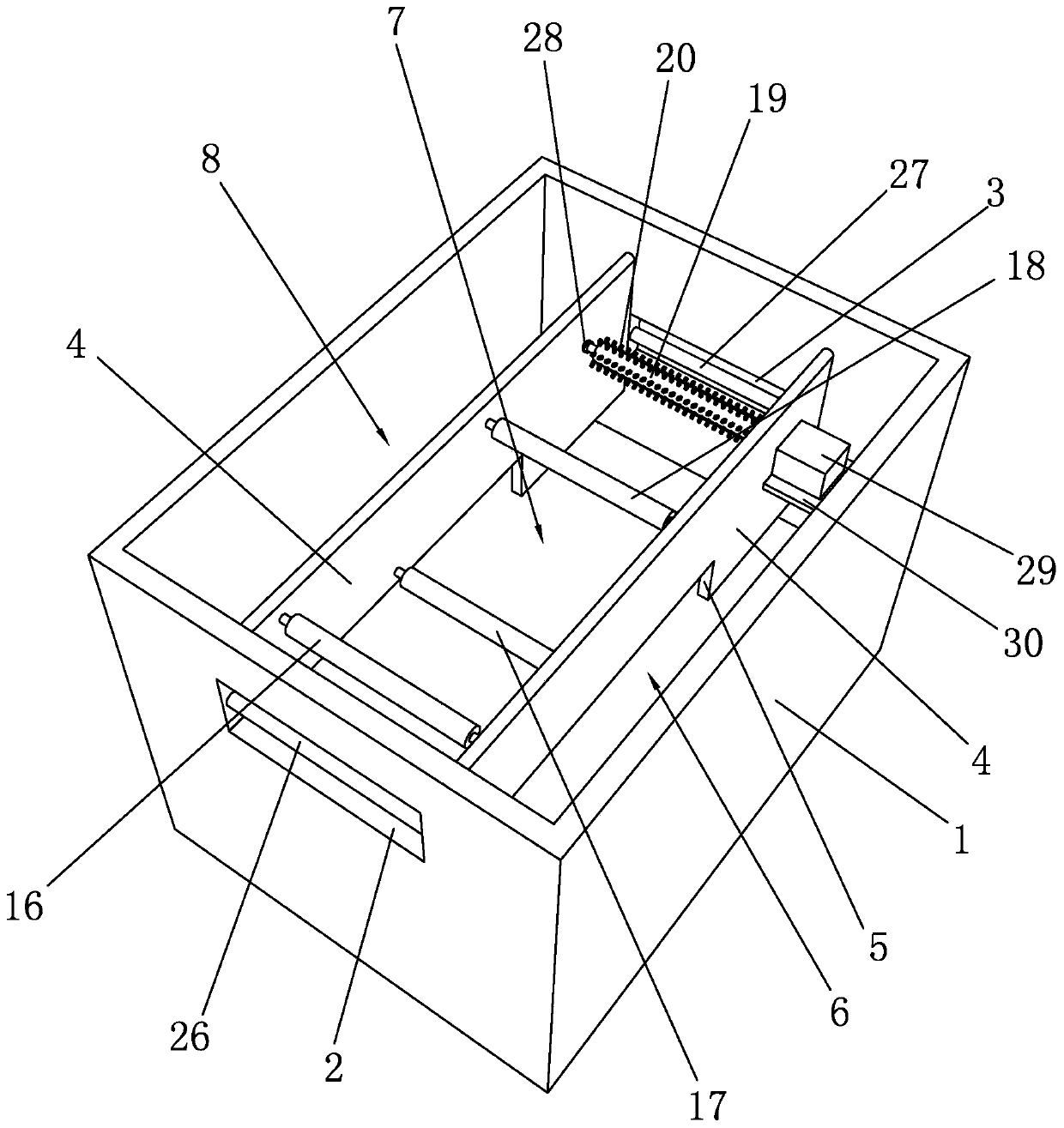

[0027] Such as Figure 1 to Figure 5 As shown, it is a fabric humidifier for textile machinery according to the present invention, which includes a box body 1, the left end of the box body 1 is provided with a cloth inlet groove 2, the right end of the box body 1 is provided with a cloth outlet groove 3, and the cloth inlet groove 2 is provided with There is a cloth feeding roller 26, and a cloth feeding roller 27 is arranged in the cloth outlet trough 3. The design of the cloth feeding roller 26 is more convenient for the cloth to enter the box body 1 for humidification treatment, and prevents the cloth from entering the box body 1. Friction occurs on the side wall of the cloth, and the design of the cloth roller 27 can facilitate the output of the cloth from the casing 1, and avoid friction with the side wall of the cloth outlet trough 3 when the cloth is output from the casing 1.

[0028] There are two spacers 4 arranged horizontally and symmetrically in the box body 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com